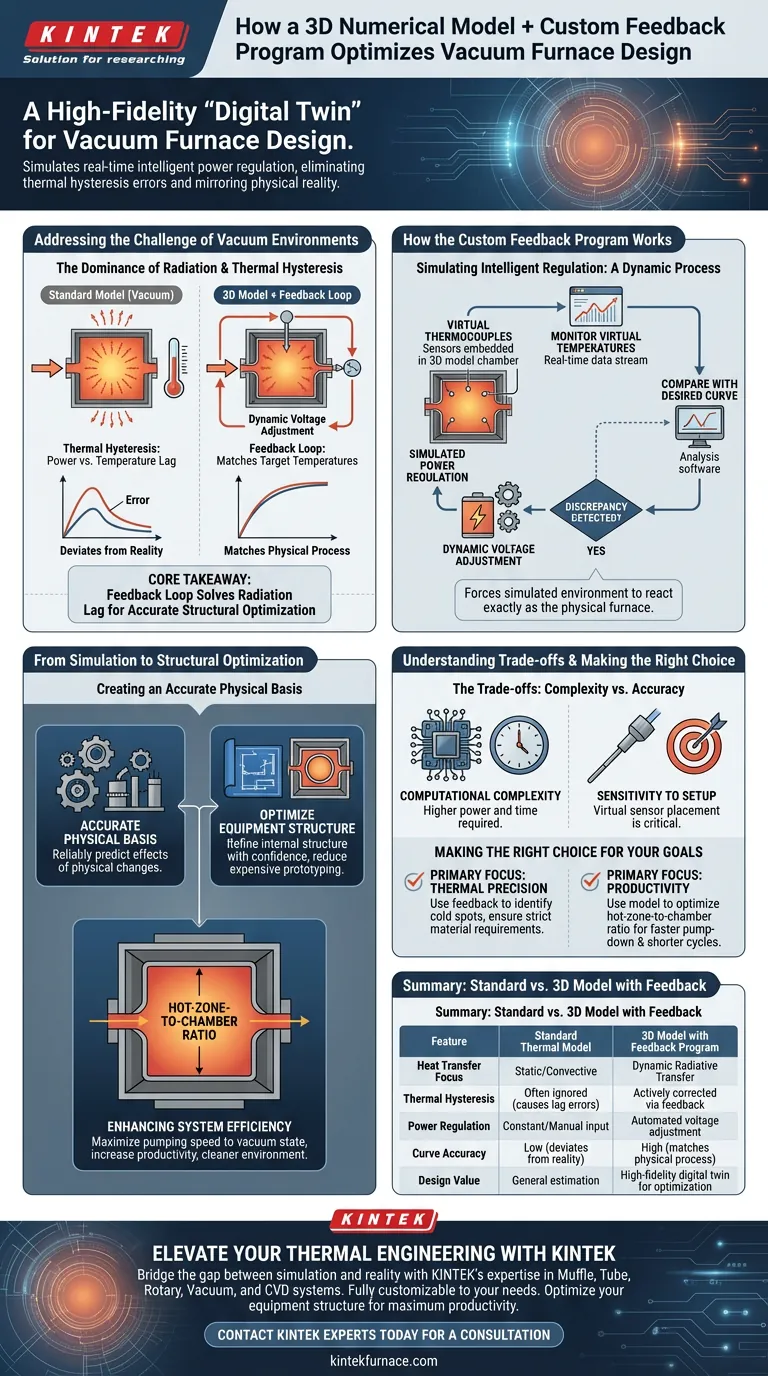

A three-dimensional numerical model combined with a custom temperature-voltage feedback program serves as a high-fidelity "digital twin" for vacuum furnace design. By simulating real-time intelligent power regulation, this method actively monitors virtual temperatures and automatically adjusts input voltage. This dynamic process eliminates the predictive errors caused by thermal hysteresis, ensuring the simulation mirrors the physical reality of vacuum heating.

Core Takeaway: Standard thermal models often fail in vacuum environments due to the lag caused by radiation heat transfer. This advanced approach solves that by integrating a feedback loop that dynamically adjusts voltage to match target temperatures, providing a mathematically accurate foundation for structural optimization.

Addressing the Challenge of Vacuum Environments

The Dominance of Radiation

In a vacuum furnace, convective heat transfer is virtually non-existent. The system relies almost exclusively on radiation heat transfer to heat the workload.

Understanding Thermal Hysteresis

Radiation transfer creates a distinct disconnect between the power applied and the immediate temperature change. This phenomenon, known as thermal hysteresis, causes a lag that static models frequently miscalculate.

The Limitation of Standard Models without Feedback

Without accounting for this lag, a standard simulation will produce a heating curve that deviates from the actual process. This discrepancy renders the model unreliable for making precise structural changes to the equipment.

How the Custom Feedback Program Works

Simulating Intelligent Regulation

The custom program is designed to mimic the intelligent power regulation systems used in actual production environments. It transforms the model from a passive observation into an active simulation.

The Monitoring Process

The system places "virtual thermocouples" within the 3D space to monitor temperatures in real-time. It constantly compares these simulated readings against the desired process curve.

Dynamic Voltage Adjustment

When a discrepancy is detected, the program automatically adjusts the input voltage within the simulation. This creates a feedback loop that forces the simulated environment to react exactly as the physical furnace would.

Matching the Heating Curves

The result is a simulated heating curve that aligns perfectly with the actual process curve. This alignment validates the model as an accurate representation of the furnace's physical behavior.

From Simulation to Structural Optimization

Creating an Accurate Physical Basis

Once the feedback loop ensures the heating curve is accurate, the model provides a reliable physical basis for design. Engineers can now predict exactly how physical changes will affect thermal performance.

Optimizing Equipment Structure

With a validated model, designers can refine the internal structure of vacuum sintering equipment with confidence. This reduces the need for expensive physical prototyping.

Enhancing System Efficiency

Accurate modeling allows for the optimization of critical design elements, such as the hot-zone-to-chamber ratio. A well-designed ratio ensures the pumping system reaches a vacuum state more quickly, maximizing productivity and maintaining a cleaner work environment.

Understanding the Trade-offs

Computational Complexity

Implementing a real-time feedback loop within a 3D numerical model significantly increases the complexity of the simulation. It requires more computational power and time than a simple, linear thermal analysis.

Sensitivity to Setup

Because the system mimics a feedback loop, the initial setup of the "virtual sensors" is critical. Placing simulated thermocouples in the wrong location can lead to over-correction or under-heating in the model, just as it would in real life.

Making the Right Choice for Your Design Goals

If you are designing vacuum sintering equipment, applying this modeling approach allows you to balance precision with efficiency.

- If your primary focus is Thermal Precision: Use the feedback program to identify cold spots and ensure the heating curve matches the strict requirements of the material being processed.

- If your primary focus is Productivity: Use the model to optimize the hot-zone-to-chamber ratio, ensuring faster vacuum pump-down times and shorter cycle durations.

By virtually eliminating the gap between simulation and reality, you turn the design process from a guessing game into an exact science.

Summary Table:

| Feature | Standard Thermal Model | 3D Model with Feedback Program |

|---|---|---|

| Heat Transfer Focus | Static/Convective | Dynamic Radiative Transfer |

| Thermal Hysteresis | Often ignored (causes lag errors) | Actively corrected via feedback |

| Power Regulation | Constant/Manual input | Automated voltage adjustment |

| Curve Accuracy | Low (deviates from reality) | High (matches physical process) |

| Design Value | General estimation | High-fidelity digital twin for optimization |

Elevate Your Thermal Engineering with KINTEK

Bridge the gap between simulation and reality with KINTEK’s industry-leading expertise. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to your unique thermal processing needs.

Whether you are a researcher or an industrial manufacturer, our lab high-temp furnaces are designed to provide the precision and efficiency your materials require. Let us help you optimize your equipment structure for maximum productivity.

Contact KINTEK Experts Today for a Consultation

Visual Guide

References

- Mao Li, Hesong Li. Numerical simulation of the heating process in a vacuum sintering electric furnace and structural optimization. DOI: 10.1038/s41598-024-81843-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are the different types of vacuum furnaces? Find the Perfect Fit for Your Process

- What types of heat treatment processes can be performed in a vacuum furnace? Unlock Superior Material Quality and Control

- What materials and features does the vacuum chamber have? Discover Its Design for Safe, High-Temp Processing

- What is the function of a flow-guiding grille in a vacuum high-pressure gas quenching furnace? Ensure Uniform Cooling

- What temperature range can most vacuum furnace systems operate within? Discover the Capabilities for Your Process

- Why use a vacuum oven for composite fillers? Protect Material Integrity & Prevent Oxidation

- What are the main functions of an annealing furnace? Achieve Precise Material Control and Enhanced Performance

- What are the main advantages of multi-chamber vacuum furnaces? Boost Efficiency and Cut Costs