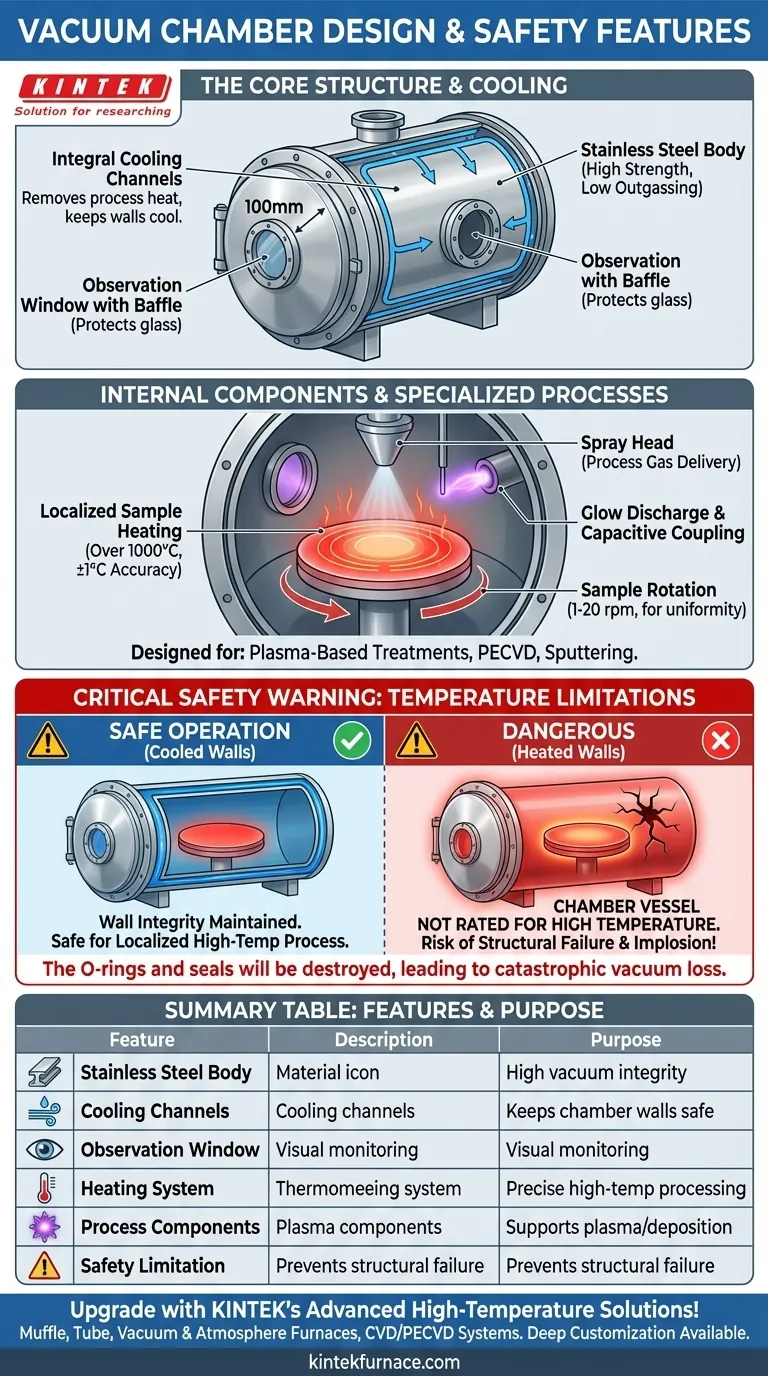

In short, the vacuum chamber is constructed from stainless steel and features a front-door design with an observation window and internal cooling channels. Its specific internal components, such as a high-temperature sample stage, a spray head, and a power supply for glow discharge, indicate it was designed for specialized processes like thin-film deposition or plasma treatment, not for heating the entire chamber vessel.

The most critical takeaway is that this chamber is designed to contain a localized high-temperature process while its walls remain cool. The fact that the chamber vessel itself is not temperature-rated is a crucial safety limitation that must be respected.

Deconstructing the Chamber's Design

To properly assess this chamber, we must look at its components not as a simple list, but as a system designed for a specific purpose. The materials and features work together to create a controlled environment.

The Core Structure: Stainless Steel Body

The chamber body is made of stainless steel. This is a standard and ideal material for high-vacuum applications due to its strength, low corrosion, and low outgassing properties, meaning it doesn't release trapped gases that would contaminate the vacuum.

The physical design is a front-door type with a diameter of 245mm and a height of 300mm, allowing for easy access to the internal components.

The Critical Safety Feature: Integral Cooling

The presence of integral cooling channels is the most important structural feature. These channels allow a fluid, typically water, to circulate through the chamber walls.

Their purpose is to remove heat generated by the process inside the chamber, keeping the chamber body, welds, and vacuum seals at a safe, near-ambient temperature.

Access and Observation

The chamber includes a 100mm observation window, which is essential for monitoring the process visually.

The inclusion of a baffle is a key detail. This shield protects the glass window from being coated by process materials (deposition) or damaged by intense heat, ensuring clear observation over time.

Understanding the Internal Components and Intended Use

The components inside the chamber reveal its original application. This is not just an empty box; it's a specialized reactor.

The Heating System: Localized Sample Heating

The system supports sample heating to over 1000°C with ±1°C accuracy. This specification refers exclusively to the 100mm diameter sample stand, not the entire chamber.

Heat is delivered directly to the sample, allowing for precise, high-temperature processing in a small, controlled zone. The temperature controller and power supply are designed for this specific task.

Process-Specific Features

The chamber includes a 100mm spray head and electronics for capacitive coupling and glow discharge. These are tell-tale signs of a system designed for plasma-based processes.

Such processes could include Plasma-Enhanced Chemical Vapor Deposition (PECVD), sputtering, or surface cleaning and modification. The gas supply nozzle and spray head deliver precursor gases or materials to the sample surface.

Sample Manipulation

The sample stand features an adjustable rotation speed of 1-20 rpm. This is used to ensure that the deposition or treatment is applied uniformly across the entire surface of the sample.

Understanding the Critical Trade-offs and Risks

A vacuum chamber is a system of balanced constraints. Understanding its limitations is essential for safe operation.

The "Not Rated for Temperature" Warning

This is the single most important safety consideration. This statement means the chamber vessel itself cannot be heated. Its structural integrity is only guaranteed near room temperature.

The O-rings or gaskets that create the vacuum seal are typically made of elastomers that would be destroyed by high temperatures, leading to a catastrophic loss of vacuum.

The Risk of High-Temperature Operation

Attempting to heat the entire chamber to 1100°C would be extremely dangerous. The atmospheric pressure on the outside (roughly 14.7 psi) exerts an enormous force on the chamber walls.

Heating the vessel would soften the metal, weaken welds, and destroy the seals, creating a severe risk of a structural failure and implosion. This must be avoided.

Atmosphere vs. Vacuum

The chamber is designed to either remove atmosphere to create a high vacuum or to be backfilled with a specific process gas (like argon) at a controlled low pressure. This prevents unwanted chemical reactions, such as oxidation of the sample or molten metals at high temperatures.

Making the Right Choice for Your Goal

To use this chamber safely and effectively, you must operate it within its intended design parameters.

- If your primary focus is to heat a sample internally to ~1000°C: This system is well-suited for your goal, provided the cooling system for the chamber walls is fully operational.

- If your primary focus is to perform surface deposition or plasma treatment: The chamber's features, including the spray head and glow discharge supply, are designed specifically for this purpose.

- If your primary focus is to heat the entire chamber vessel to 1100°C: Do not proceed. This is far outside the chamber's design limits and presents a significant safety hazard.

Understanding that this is a system for localized internal heating is the key to operating it successfully and safely.

Summary Table:

| Feature | Description | Purpose |

|---|---|---|

| Material | Stainless steel | High strength, low corrosion, minimal outgassing for vacuum integrity |

| Cooling Channels | Integral water-cooling system | Removes heat to keep chamber walls cool and safe |

| Observation Window | 100mm with baffle | Allows visual monitoring while protecting from damage |

| Heating System | Localized sample stage up to 1000°C with ±1°C accuracy | Enables precise high-temperature processing of samples |

| Process Components | Spray head, glow discharge electronics, rotation (1-20 rpm) | Supports plasma-based treatments like PECVD and uniform deposition |

| Safety Limitation | Chamber not rated for high-temperature heating | Prevents structural failure and ensures safe operation |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for safe and efficient processes. Contact us today to discuss how we can enhance your research and development!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance