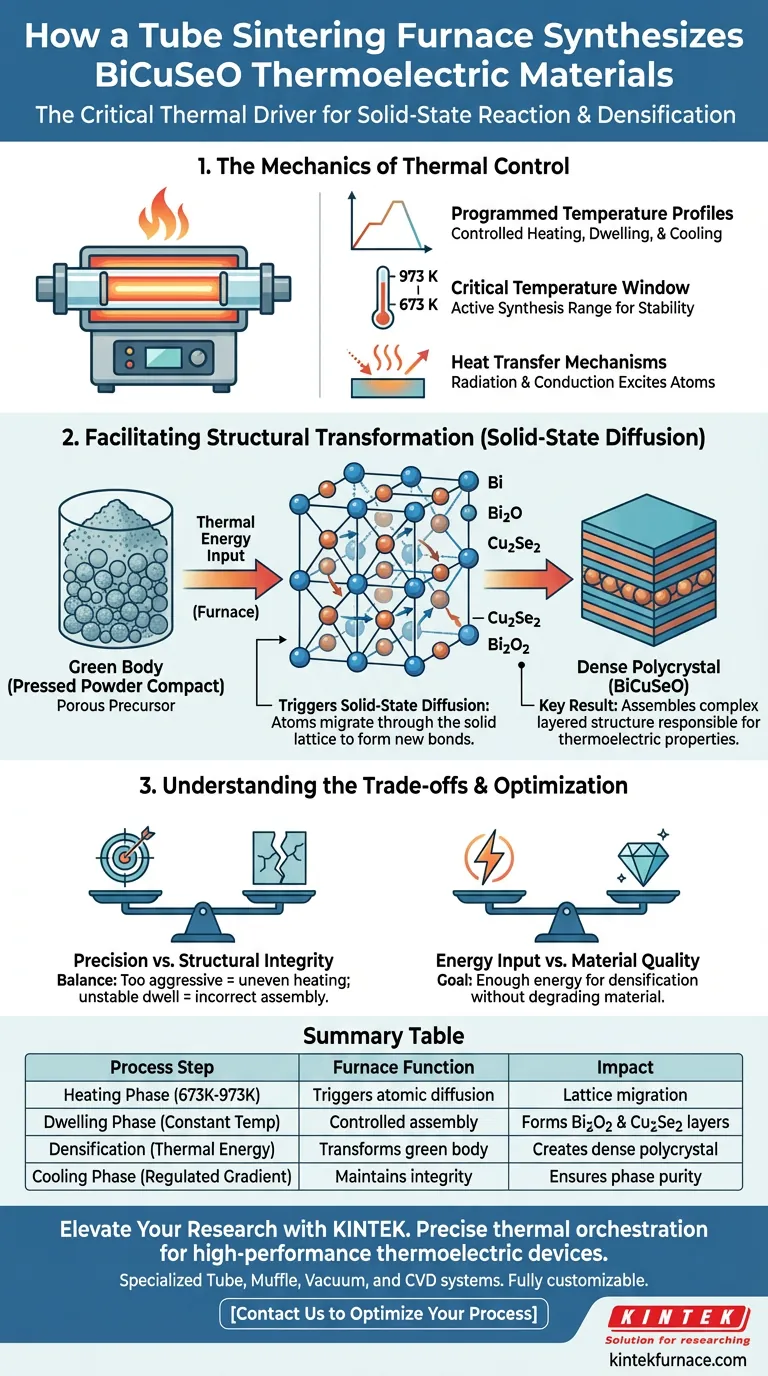

A laboratory tube sintering furnace serves as the critical thermal driver that enables the synthesis of BiCuSeO thermoelectric materials. By executing precise, programmed temperature curves typically ranging from 673 K to 973 K, the furnace applies thermal energy through radiation and conduction to trigger the solid-state diffusion necessary for material formation.

The furnace does not merely heat the sample; it orchestrates a precise transformation from a pressed "green body" to a dense polycrystal by driving the atomic assembly of Bi2O2 and Cu2Se2 layers.

The Mechanics of Thermal Control

Programmed Temperature Profiles

The success of the synthesis relies on the furnace's ability to execute a multi-stage thermal schedule.

This involves controlled heating rates, specific constant temperature phases (dwelling), and regulated cooling periods.

The Critical Temperature Window

The primary reference indicates that the active synthesis typically occurs within a window of 673 K to 973 K.

Maintaining stability within this range is essential, as deviations can alter the reaction kinetics or fail to fully activate the diffusion process.

Heat Transfer Mechanisms

Inside the furnace chamber, thermal energy is transferred to the BiCuSeO samples through radiation and conduction.

This energy transfer is the catalyst that excites the atoms within the precursor materials, allowing them to overcome energy barriers and move into their correct lattice positions.

Facilitating the Structural Transformation

Triggering Solid-State Diffusion

The core function of the thermal energy is to initiate solid-state diffusion reactions.

Unlike liquid-phase reactions, this process relies on atoms migrating through the solid lattice to form new chemical bonds.

Forming the Layered Architecture

BiCuSeO is defined by its specific crystal structure, consisting of alternating Bi2O2 insulating layers and Cu2Se2 conductive layers.

The sintering furnace drives the assembly of this complex layered structure, which is directly responsible for the material's thermoelectric properties.

Densification of the Green Body

Before entering the furnace, the material exists as a pressed powder compact, known as a green body.

The sintering process eliminates the voids between powder particles, transforming the porous compact into a mechanically robust, dense polycrystal.

Understanding the Trade-offs

Precision vs. Structural Integrity

While high temperatures facilitate faster diffusion, the process requires exacting control over the thermal field.

If the programmed curve is too aggressive, you risk uneven heating; if the constant temperature phase is unstable, the layered structure may not assemble correctly.

Energy Input vs. Material Quality

The goal is to provide enough energy to drive densification without degrading the material.

The furnace must balance the thermal input to maximize electrical transport properties while ensuring the correct structural phases are formed.

Making the Right Choice for Your Goal

To optimize your synthesis of BiCuSeO, consider how you program the furnace based on your specific objectives:

- If your primary focus is Structural Homogeneity: Ensure your specific programmed temperature curve includes a stable "constant temperature" phase between 673 K and 973 K to allow complete diffusion.

- If your primary focus is Material Density: Prioritize the precision of the thermal field control to effectively transform the porous green body into a solid polycrystal.

Precise thermal regulation is the key to converting raw powder into a high-performance thermoelectric device.

Summary Table:

| Process Step | Furnace Function | Impact on BiCuSeO |

|---|---|---|

| Heating Phase | Programmed 673 K - 973 K | Triggers atomic diffusion and lattice migration |

| Dwelling Phase | Constant Temperature Control | Assemblies alternating Bi2O2 and Cu2Se2 layers |

| Densification | Thermal Energy Transfer | Transforms porous 'green body' into dense polycrystal |

| Cooling Phase | Regulated Thermal Gradient | Maintains structural integrity and phase purity |

Elevate Your Thermoelectric Research with KINTEK

Precise thermal orchestration is the difference between a porous sample and a high-performance thermoelectric device. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Tube, Muffle, Vacuum, and CVD systems designed to meet the exacting temperature profiles required for complex material synthesis like BiCuSeO.

Whether you need custom dimensions or advanced multi-stage programming, our lab high-temp furnaces are fully customizable for your unique research needs. Contact us today to optimize your sintering process and achieve superior structural homogeneity.

Visual Guide

References

- N. P. Madhukar, Saikat Chattopadhyay. Role of sintering temperature in modulating the charge transport of BiCuSeO thermoelectric system: correlations to the microstructure. DOI: 10.1007/s00339-023-07218-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What role does a high-temperature tube furnace play in the post-treatment of Ir-TiO2 samples? Master Material Purity

- How does an atmosphere tube furnace support energy conservation and environmental protection? Boost Efficiency and Cut Emissions

- What maintenance practices are recommended for a multi zone tube furnace? Ensure Safety and Precision in Your Lab

- What is the working principle of a vacuum tube experimental electric furnace? Master Precise Atmosphere Control

- How are tubular furnaces used in chemical synthesis? Unlock Precise Material Creation

- What are the key features of a split tube furnace? Unlock Superior Access and Control for Complex Samples

- What is the importance of maintaining an argon atmosphere in a quartz tube furnace for LiFePO4? Achieve Pure Synthesis

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency