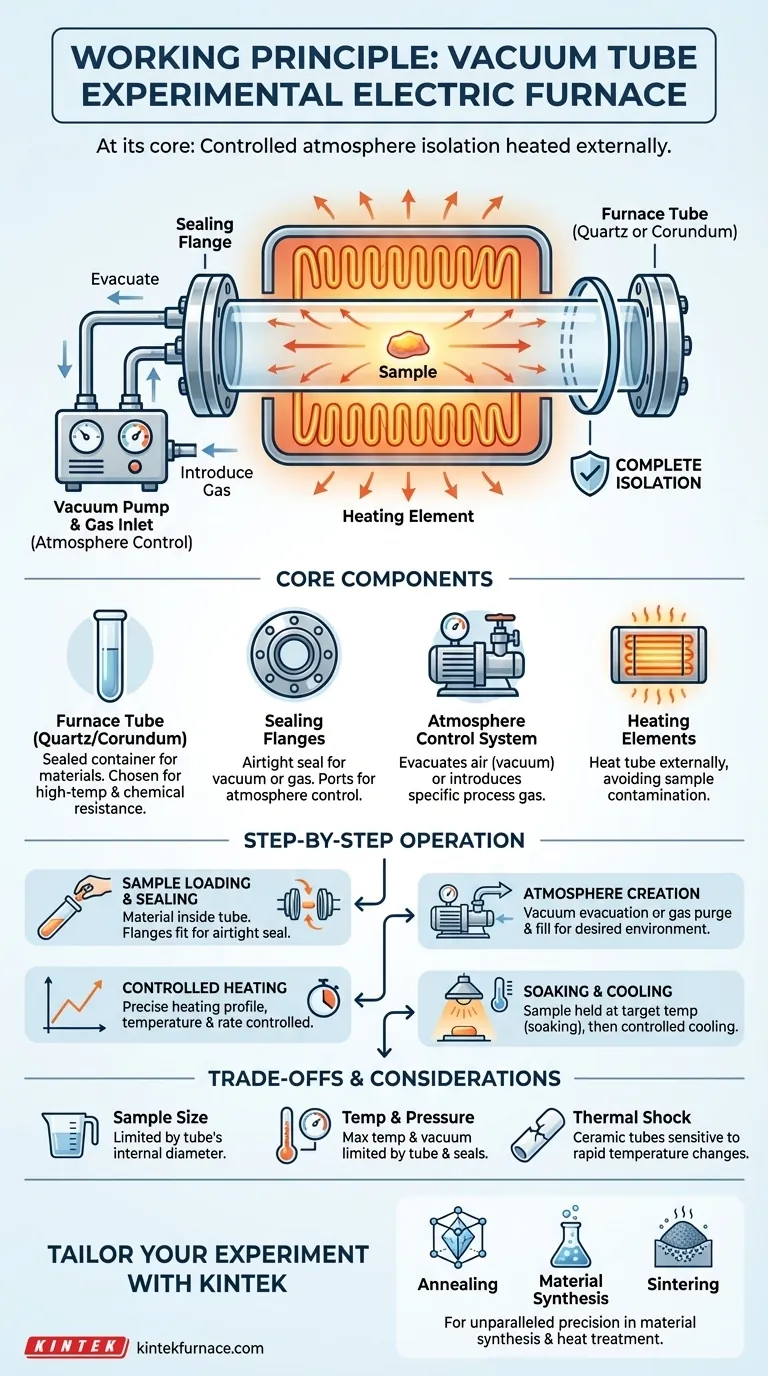

At its core, a vacuum tube experimental electric furnace works by creating a highly controlled environment inside a sealed tube, which is then heated externally. This process involves placing a sample into a quartz or corundum tube, sealing it with specialized flanges, and then using a vacuum pump to remove air or an inlet to introduce a specific gas before the heating cycle begins.

The crucial principle isn't just heating; it's the complete isolation of the experimental sample. The tube acts as a self-contained chamber, allowing you to precisely control the atmosphere (from a vacuum to a specific gas) independently of the external heating elements.

The Core Components and Their Roles

To fully grasp the working principle, it's essential to understand the function of each key component. These parts work in concert to achieve a precise, repeatable experimental condition.

The Furnace Tube (Quartz or Corundum)

The tube is the heart of the furnace, serving as the sealed container for your materials. The choice between quartz and corundum is based on the temperature requirements of your experiment.

These materials are chosen for their high-temperature resistance and chemical inertness, ensuring they don't react with the sample.

The Sealing Flanges

Stainless steel flanges are attached to both ends of the tube. Their primary job is to create an airtight seal, which is critical for maintaining a vacuum or a pure gas atmosphere.

These flanges also feature ports for connecting a vacuum pump and gas inlets, providing the gateway for atmosphere control.

The Atmosphere Control System

This system typically consists of a vacuum pump and a gas inlet valve. The pump is used to evacuate the air and other reactive gases from the sealed tube, preventing oxidation and contamination.

Alternatively, the gas inlet allows you to purge the tube and introduce a specific inert (like argon) or reactive atmosphere required for the experiment.

The Heating Elements

The heating elements are located in the main body of the furnace, positioned outside the sealed tube. They generate the thermal energy that heats the tube and, in turn, the sample inside it.

This external heating method ensures that the elements do not contaminate the sample's controlled atmosphere.

A Step-by-Step Operational Breakdown

The working principle is best understood as a sequence of controlled steps, each serving a distinct purpose.

Step 1: Sample Loading and Sealing

First, the experimental material is placed inside the tube. The sealing flanges are then carefully fitted onto the ends of the tube to ensure a completely airtight chamber.

Step 2: Atmosphere Creation

Next, the atmosphere control system is engaged. The vacuum pump evacuates the tube to the desired pressure level, or the chamber is purged and filled with a specific process gas.

Step 3: Controlled Heating

Once the atmosphere is stable, the furnace's temperature controller is programmed to heat the tube. The system follows a precise profile, controlling the heating rate and final temperature.

Step 4: Soaking and Cooling

The furnace holds the sample at the target temperature for a predetermined duration (known as soaking). After the process is complete, the furnace begins a controlled cooling cycle, bringing the material safely back to room temperature.

Understanding the Trade-offs

While powerful, this technology has practical limitations that are important to consider for successful experimental design.

Sample Size Limitations

The internal diameter of the furnace tube inherently restricts the size and volume of the sample that can be processed at one time.

Temperature and Pressure Constraints

The maximum operating temperature is dictated by the tube material (corundum tubes can withstand higher temperatures than quartz). Likewise, the quality of the vacuum is limited by the pump and the integrity of the flange seals.

Risk of Thermal Shock

The ceramic tubes, especially quartz, can be sensitive to rapid temperature changes. An improperly programmed heating or cooling rate can cause the tube to crack, ruining the experiment and requiring replacement.

Making the Right Choice for Your Experiment

Understanding the furnace's working principle allows you to tailor its use to your specific scientific or industrial goal.

- If your primary focus is annealing or purifying materials: The key is achieving a deep vacuum to eliminate oxygen and prevent any unwanted chemical reactions.

- If your primary focus is material synthesis in a specific environment: The key is the system's ability to purge the chamber and introduce a controlled, flowing gas atmosphere.

- If your primary focus is high-temperature sintering: The key is selecting the right tube material, such as high-purity corundum, that can withstand the extreme thermal demands.

By mastering these principles, you transform the vacuum tube furnace from a simple heater into a precision instrument for advanced material innovation.

Summary Table:

| Component | Primary Function |

|---|---|

| Furnace Tube (Quartz/Corundum) | Sealed chamber for the sample; resistant to high temperatures and chemical reactions. |

| Sealing Flanges | Create an airtight seal on tube ends; feature ports for vacuum and gas connections. |

| Atmosphere Control System | Evacuates air (vacuum pump) or introduces a specific process gas (inlet valve). |

| Heating Elements | Heat the tube externally to avoid contaminating the sample's controlled atmosphere. |

Ready to achieve unparalleled precision in your material synthesis or heat treatment processes?

KINTEK's advanced vacuum tube furnaces are engineered for researchers and engineers who demand exact control over temperature and atmosphere. Leveraging our exceptional R&D and in-house manufacturing, we provide solutions like our Muffle, Tube, and Vacuum & Atmosphere Furnaces, complemented by strong deep customization capabilities to meet your unique experimental requirements.

Contact our experts today to discuss how a KINTEK furnace can be tailored to power your innovation.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab