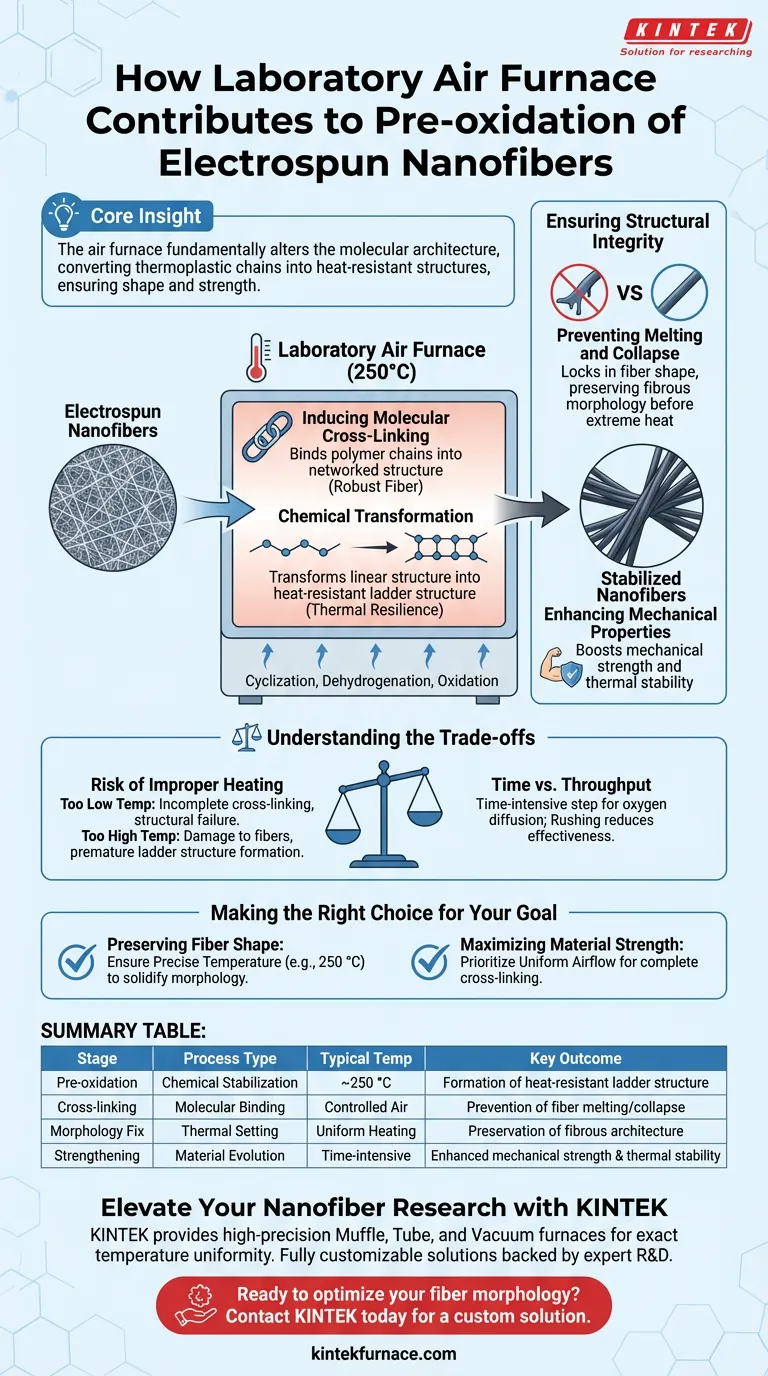

The primary role of a laboratory air furnace in the context of electrospun nanofibers is to execute the critical stabilization or pre-oxidation phase. By subjecting fibers to a controlled air environment at specific temperatures—typically around 250 °C—the furnace facilitates a chemical transformation that prevents the material from melting during subsequent processing.

Core Insight: The air furnace does not merely dry the fibers; it fundamentally alters their molecular architecture. It converts thermoplastic chains into heat-resistant structures, ensuring the fibers retain their shape and strength during high-temperature carbonization.

The Mechanics of Stabilization

Inducing Molecular Cross-Linking

The heat treatment provided by the furnace drives cross-linking within the polymer molecular chains.

This process binds the polymer chains together, creating a networked structure. This network is essential for shifting the material from a simple plastic to a robust, stable fiber.

Chemical Transformation

Inside the furnace, specific reactions such as cyclization, dehydrogenation, and oxidation occur, particularly in polymers like polyacrylonitrile (PAN).

These reactions transform the polymer's original linear structure into a heat-resistant ladder structure. This structural evolution is what ultimately grants the fiber its thermal resilience.

Ensuring Structural Integrity

Preventing Melting and Collapse

Without the pre-oxidation step performed in the air furnace, electrospun fibers remain thermoplastic.

If these untreated fibers were exposed to the extreme heat of carbonization, they would simply melt or collapse. The furnace "locks in" the fiber shape, preserving the fibrous morphology.

Enhancing Mechanical Properties

Beyond shape retention, the furnace treatment significantly boosts the physical attributes of the material.

The cross-linking process directly enhances the mechanical strength of the nanofibers. It also improves thermal stability, preparing the material to withstand temperatures far exceeding the 250 °C stabilization point.

Understanding the Trade-offs

The Risk of Improper Heating

The stabilization process is highly sensitive to temperature accuracy.

If the furnace temperature is too low, the cross-linking will be incomplete, leading to structural failure later. Conversely, excessive heat can damage the fibers before the ladder structure fully forms.

Time vs. Throughput

Achieving full stabilization requires a specific duration in the air environment to ensure oxygen diffuses through the fiber diameter.

Rushing this stage reduces the effectiveness of the oxidation reactions. You must accept that this is a time-intensive step necessary to guarantee the quality of the final carbonized product.

Making the Right Choice for Your Goal

To ensure your electrospun fibers perform as intended, consider how the furnace parameters align with your specific objectives.

- If your primary focus is preserving fiber shape: Ensure the furnace maintains a precise temperature (e.g., 250 °C) to solidify the fibrous morphology before carbonization.

- If your primary focus is maximizing material strength: Prioritize a furnace with uniform airflow to guarantee complete cross-linking and ladder structure formation throughout the fiber mat.

The laboratory air furnace is the gatekeeper that determines whether your nanofibers become high-performance materials or simply melted plastic.

Summary Table:

| Stage | Process Type | Typical Temp | Key Outcome |

|---|---|---|---|

| Pre-oxidation | Chemical Stabilization | ~250 °C | Formation of heat-resistant ladder structure |

| Cross-linking | Molecular Binding | Controlled Air | Prevention of fiber melting/collapse during carbonization |

| Morphology Fix | Thermal Setting | Uniform Heating | Preservation of fibrous architecture and shape |

| Strengthening | Material Evolution | Time-intensive | Enhanced mechanical strength and thermal stability |

Elevate Your Nanofiber Research with KINTEK

Don't let improper thermal stabilization compromise your material integrity. KINTEK provides high-precision Muffle, Tube, and Vacuum furnaces designed to deliver the exact temperature uniformity required for complex pre-oxidation and carbonization workflows.

Whether you are a researcher or a commercial manufacturer, our systems are fully customizable to meet your specific stabilization parameters. Backed by expert R&D, KINTEK lab high-temp furnaces ensure your electrospun fibers achieve peak mechanical strength and thermal resilience.

Ready to optimize your fiber morphology? Contact KINTEK today for a custom solution.

Visual Guide

References

- Qinghua Li, Shaoming Huang. Efficient Polytelluride Anchoring for Ultralong-Life Potassium Storage: Combined Physical Barrier and Chemisorption in Nanogrid-in-Nanofiber. DOI: 10.1007/s40820-023-01318-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is a retort furnace and what are its key features? Discover Precision Heating for Superior Material Processing

- What types of gases are used in controlled atmosphere furnaces? Optimize Material Protection and Transformation

- Why are retort furnaces considered versatile tools? Unlock Precise Thermal Processing Control

- What gases are commonly used in heat treatment furnace atmospheres? Optimize Your Process with the Right Gas Mix

- What types of gases can a controlled atmosphere furnace handle? Master Inert and Reactive Gases for Your Lab

- Why is a high-purity argon protection system required for CP-Ti? Protect Ductility in Titanium Heat Treatment

- Why would a heat treatment process require an inert atmosphere furnace? Prevent Oxidation and Ensure Material Integrity

- Why is it necessary to use a high-purity argon gas protective atmosphere? Ensure Precision in Brazing Filler Melting