In the world of thermal processing, few tools match the adaptability of a retort furnace. Their versatility stems from a single, powerful design feature: a sealed inner chamber, or "retort," that isolates the material being processed. This allows for precise and independent control over both the atmosphere and temperature, enabling a wide range of sensitive applications from metallurgy and ceramics to advanced scientific research.

The core reason for a retort furnace's versatility is not just its ability to heat, but its ability to create a completely controlled and isolated process environment. The sealed retort separates the material from the furnace's heating elements and ambient air, unlocking advanced processes that are impossible in a standard oven.

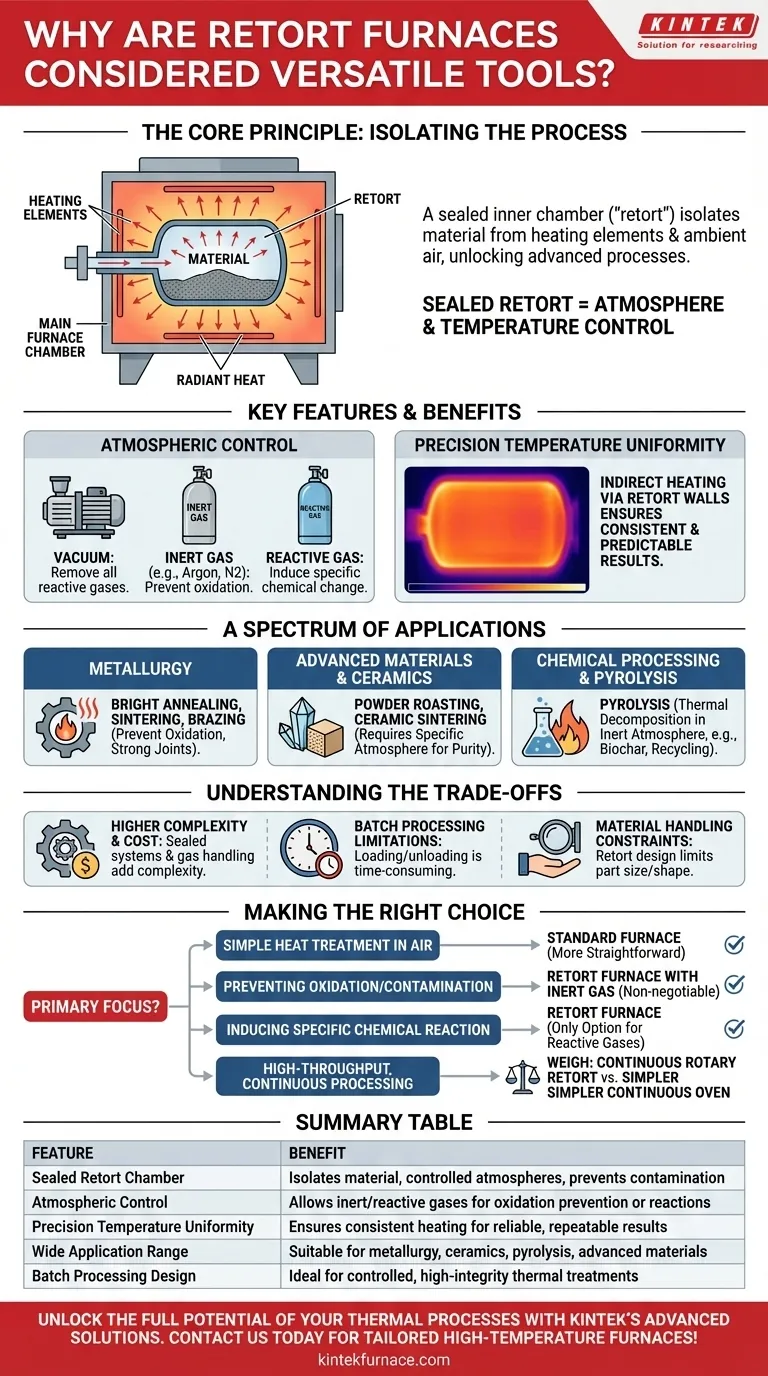

The Core Principle: Isolating the Process

To understand the versatility of a retort furnace, you must first understand the function of the retort itself. It is the key differentiator that sets this equipment apart.

What is a Retort?

A retort is a sealed, gas-tight vessel placed inside the main furnace chamber. Your material goes inside this retort, not into the main furnace.

The furnace's heating elements heat the outside of the retort, and the retort, in turn, radiates heat evenly to the material inside. Think of it as a high-integrity reaction chamber placed inside a powerful oven.

The Power of Atmospheric Control

Because the retort is sealed, you have complete control over the gaseous environment surrounding your material. This is the furnace's most powerful feature.

You can pull a vacuum to remove all reactive gases. You can also introduce specific gases, such as inert gases (like argon or nitrogen) to prevent oxidation, or reactive gases to induce a specific chemical change in the material.

Precision Temperature Uniformity

By heating the material indirectly via the retort walls, these furnaces typically achieve excellent temperature uniformity. This ensures that the entire batch of material is processed at the exact same temperature, which is critical for achieving consistent and predictable results.

A Spectrum of Applications

The ability to finely control both atmosphere and temperature opens up a vast range of applications across numerous industries.

Metallurgy and Metal Treatment

In metallurgy, preventing oxidation is paramount for many processes. Retort furnaces are essential for bright annealing, a process that softens metals without causing surface discoloration.

They are also used for sintering (fusing powdered metal into a solid mass) and brazing in a controlled atmosphere to ensure strong, clean joints.

Advanced Materials and Ceramics

For creating advanced materials, purity is everything. Retort furnaces are used for powder roasting and ceramic sintering where a specific atmosphere is required to achieve the desired final material properties.

Any unwanted reaction with oxygen or other elements in the air can compromise the integrity of the final product.

Chemical Processing and Pyrolysis

Retort furnaces are fundamental tools for high-temperature chemistry. They enable pyrolysis, the thermal decomposition of materials at elevated temperatures in an inert atmosphere.

This is critical for applications ranging from creating biochar to recycling plastics and electronics, where burning the material must be avoided.

Understanding the Trade-offs

While highly versatile, retort furnaces are not the universal solution for every heating task. Understanding their limitations is key to making an informed decision.

Higher Complexity and Cost

The addition of a sealed retort, gas-handling systems, and vacuum pumps makes these furnaces more complex and expensive than a simple air-atmosphere box furnace. The operational procedures are also more involved.

Batch Processing Limitations

Most standard retort furnaces are designed for batch processing. Loading, sealing, processing, and unloading a single batch can be time-consuming.

While rotary retort furnaces exist for continuous processing, they represent an even greater level of complexity and investment compared to simpler continuous belt furnaces.

Material Handling Constraints

Getting materials into and out of a sealed retort can be more cumbersome than simply opening the door of a box furnace. The design of the retort may place constraints on the size and shape of the parts that can be processed.

Making the Right Choice for Your Goal

The decision to use a retort furnace hinges entirely on the requirements of your process, specifically the need for atmospheric control.

- If your primary focus is simple heat treatment in air: A standard, non-retort furnace is likely more straightforward and cost-effective.

- If your primary focus is preventing any oxidation or contamination: A retort furnace with an inert gas atmosphere is non-negotiable.

- If your primary focus is inducing a specific chemical reaction: A retort furnace is the only tool that allows you to safely introduce reactive gases at high temperatures.

- If your primary focus is high-throughput, continuous processing: You must weigh the benefits of a continuous rotary retort furnace against a simpler continuous oven that operates in air.

Ultimately, the retort furnace's versatility is a direct result of its ability to decouple the heating environment from the process environment, offering a level of control that unlocks a world of advanced material processing.

Summary Table:

| Feature | Benefit |

|---|---|

| Sealed Retort Chamber | Isolates material, enabling controlled atmospheres and preventing contamination |

| Atmospheric Control | Allows use of inert or reactive gases for oxidation prevention or chemical reactions |

| Precision Temperature Uniformity | Ensures consistent heating for reliable, repeatable results |

| Wide Application Range | Suitable for metallurgy, ceramics, pyrolysis, and advanced materials processing |

| Batch Processing Design | Ideal for controlled, high-integrity thermal treatments in various industries |

Unlock the full potential of your thermal processes with KINTEK's advanced retort furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your efficiency and results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing