A high vacuum furnace ensures purity through a dual mechanism of active extraction and strict atmospheric isolation. By maintaining a controlled low-pressure environment, the furnace actively removes gaseous by-products released during binder decomposition while simultaneously shielding reactive titanium and niobium atoms from external contaminants like oxygen and nitrogen.

The vacuum environment acts as both a shield and a broom: it prevents environmental oxidation while actively sweeping away organic impurities, ensuring that the diffusion of metal atoms occurs in a pristine state.

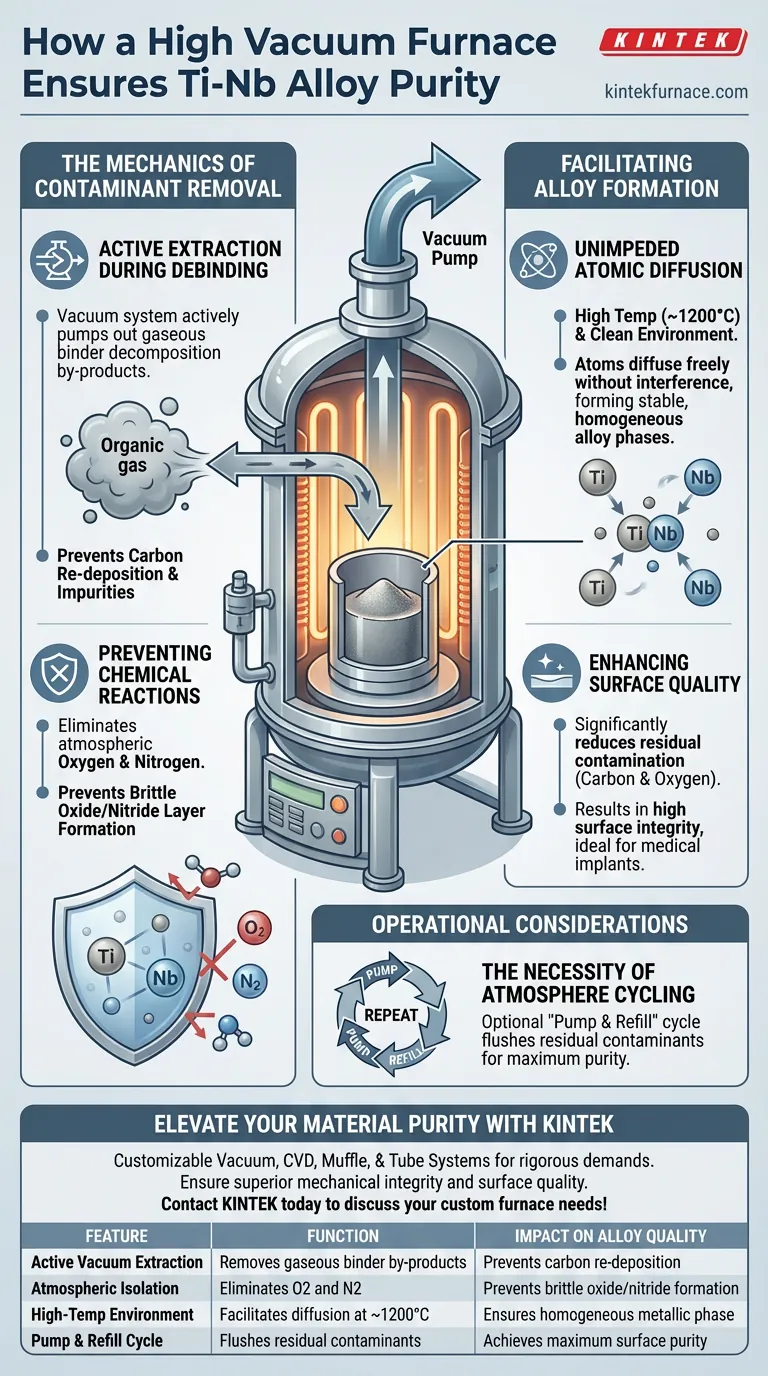

The Mechanics of Contaminant Removal

Active Extraction During Debinding

During the initial heating stages, the organic binders used to shape the alloy begin to decompose.

The vacuum system is essential here. It does not just hold a static environment; it actively pumps out the gaseous by-products resulting from this decomposition.

Without this active extraction, these gases would linger around the metal, re-depositing carbon or other impurities onto the alloy surface.

Preventing Chemical Reactions

Titanium is highly reactive, particularly prone to oxidation and nitridation when heated.

A high vacuum environment eliminates the presence of atmospheric oxygen and nitrogen.

This isolation prevents the formation of brittle oxide or nitride layers that would compromise the mechanical integrity of the final alloy.

Facilitating Alloy Formation

Unimpeded Atomic Diffusion

To create a true Ti-Nb alloy, titanium and niobium atoms must diffuse into one another.

This process typically requires temperatures around 1200 degrees Celsius.

The vacuum ensures this occurs without interference. By removing physical barriers (like oxide layers) and gaseous contaminants, the atoms can diffuse freely to form stable, homogeneous alloy phases.

Enhancing Surface Quality

For applications requiring ultra-clean surfaces, such as medical implants, vacuum sintering is superior.

It significantly reduces residual contamination from carbon and oxygen.

This results in a final product with high surface integrity, free from the inclusions that often plague atmosphere-sintered parts.

Operational Considerations and Trade-offs

The Necessity of Atmosphere Cycling

Achieving maximum purity often requires more than a simple "pump down."

Supplementary protocols suggest a "pump and refill" cycle. This involves pre-pumping a vacuum, introducing a pure atmosphere, and repeating the cycle.

While this technique significantly increases purity by flushing out residual contaminants, it adds time and complexity to the overall processing cycle. Ignoring this step in experimental or high-stakes batches can lead to inconsistent results.

Making the Right Choice for Material Integrity

To maximize the quality of your Ti-Nb alloys, consider your specific processing goals:

- If your primary focus is Avoiding Embrittlement: Prioritize a high vacuum level to strictly prevent oxidation and nitridation, which are the main causes of brittle phase formation in titanium.

- If your primary focus is Surface Purity: Implement a "pump and refill" pre-processing cycle to flush the furnace chamber of residual atmospheric contaminants before heating begins.

True material purity is not just about the temperature you reach, but the cleanliness of the environment in which that temperature is applied.

Summary Table:

| Feature | Function in Ti-Nb Processing | Impact on Alloy Quality |

|---|---|---|

| Active Vacuum Extraction | Removes gaseous binder by-products | Prevents carbon re-deposition and surface contamination |

| Atmospheric Isolation | Eliminates oxygen and nitrogen | Prevents brittle oxide/nitride layer formation |

| High-Temp Environment | Facilitates diffusion at ~1200°C | Ensures a stable, homogeneous metallic phase |

| Pump & Refill Cycle | Flushes residual contaminants | Achieves maximum surface purity for medical/aerospace use |

Elevate Your Material Purity with KINTEK

Don't let oxidation or carbon inclusions compromise your high-performance Ti-Nb alloys. KINTEK provides industry-leading vacuum solutions designed specifically for the rigorous demands of thermal debinding and sintering.

Backed by expert R&D and precision manufacturing, our range of Vacuum, CVD, Muffle, and Tube systems are fully customizable to meet your unique metallurgical needs. Whether you are producing medical implants or aerospace components, we ensure your materials achieve superior mechanical integrity and surface quality.

Ready to optimize your high-temperature processes? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Diego Michael Cornelius dos Santos, Natália de Freitas Daudt. Powder Metallurgical Manufacturing of Ti-Nb alloys Using Coarse Nb Powders. DOI: 10.1590/1980-5373-mr-2023-0478

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are the advantages of using graphite as a heating element in vacuum furnaces? Achieve Extreme Heat with Superior Stability

- Why is a high-temperature homogenization furnace treatment necessary for (CoCrNi)94Al3Ti3 alloys? Ensure Metal Purity

- How does the vacuum brazing process work? Achieve Clean, Strong Metal Joining Without Flux

- What is the necessity of using a vacuum drying oven for the 70 °C treatment of synthesized TF-COF? Essential Guide

- How does vacuum sintering improve material properties? Boost Strength, Purity, and Performance

- How does a vacuum furnace prevent oxidation and decarburization? Achieve Flawless Metal Processing with Precision Control

- How does optimizing the graphite base material improve the quality of cemented carbide sintering? Master Thermal Uniformity

- How has vacuum technology enabled high vacuum conditions in furnace chambers? Achieve Clean, Oxidation-Free Processing