At its core, vacuum brazing is a high-purity joining process where metal components are bonded together using a filler metal with a lower melting point. The entire operation occurs inside a vacuum furnace, which removes atmospheric contaminants like oxygen, preventing oxidation and resulting in an exceptionally clean, strong, and metallurgically sound joint without melting the base components themselves.

The crucial insight is that vacuum brazing leverages the absence of atmosphere as its greatest strength. By removing oxygen and other reactive gases, the process eliminates the need for chemical fluxes, allowing for the creation of intricate, high-integrity joints that would be impossible to achieve with conventional methods.

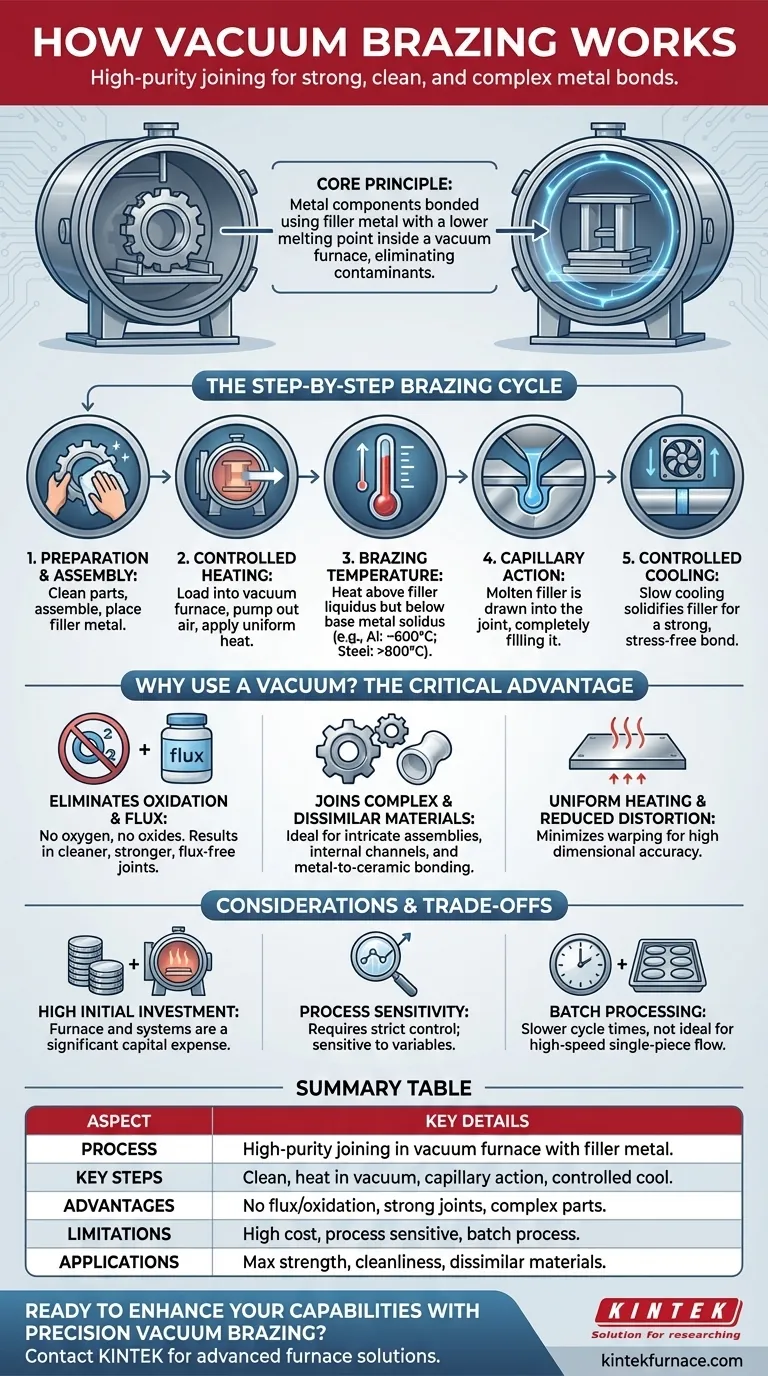

The Step-by-Step Brazing Cycle

The vacuum brazing process is a precisely controlled thermal cycle. Each stage is critical to achieving a successful and reliable joint.

1. Meticulous Preparation and Assembly

Before any heating occurs, the components must be thoroughly cleaned to remove any oils, grease, and surface oxides.

The parts are then assembled in their final configuration. The filler metal, often a thin foil or paste, is placed at or near the joint line.

2. The Controlled Heating Phase

The assembled parts are loaded into a vacuum furnace. The furnace chamber is sealed, and powerful pumps remove the air to create a high-vacuum environment.

Heat is then applied in a slow, controlled manner. This uniform heating minimizes thermal stress and prevents distortion of the components.

3. Reaching Brazing Temperature: Liquidus vs. Solidus

The furnace heats the assembly to a specific brazing temperature. This temperature is carefully chosen to be above the liquidus point (fully melted) of the filler metal but below the solidus point (starts to melt) of the base materials.

Temperature ranges vary significantly based on the materials. For example, aluminum alloys are brazed around 580-620°C, while stainless steels and superalloys require temperatures from 800°C to over 1150°C.

4. Capillary Action: The Engine of the Joint

Once the filler metal melts, a powerful physical phenomenon called capillary action takes over. The molten filler is drawn into the tight gap between the mating surfaces, completely filling the joint.

Think of how a paper towel wicks water into its fibers—the same principle pulls the molten metal into the joint, ensuring complete coverage.

5. Controlled Cooling for Joint Integrity

After a short "soak" at the brazing temperature to ensure the filler has fully flowed, the assembly is slowly and controllably cooled.

This slow cooling solidifies the filler metal, creating a strong metallurgical bond. It also prevents the introduction of residual stresses that could compromise the part's strength and dimensional stability.

Why Use a Vacuum? The Critical Advantage

The use of a vacuum is not incidental; it is the defining feature that provides the process with its unique capabilities.

Eliminating Oxidation Without Flux

In a normal atmosphere, heating metals creates a layer of oxide that acts as a barrier, preventing the filler metal from bonding properly. Traditional brazing uses a chemical flux to dissolve this oxide.

A vacuum furnace simply removes the oxygen, preventing oxides from forming in the first place. This results in cleaner, stronger joints with no risk of flux entrapment, which can cause corrosion.

Joining Complex and Dissimilar Materials

The fluxless, clean environment of vacuum brazing is ideal for joining chemically sensitive or dissimilar materials, such as metal to ceramic.

It also allows for the brazing of highly complex assemblies with internal channels that would be impossible to clean of flux residue.

Uniform Heating and Reduced Distortion

A furnace provides extremely uniform heating to the entire assembly. This minimizes temperature gradients, which are a primary cause of part warping and distortion, ensuring high dimensional accuracy.

Understanding the Trade-offs and Considerations

While powerful, vacuum brazing is not a universal solution. Understanding its limitations is key to using it effectively.

High Initial Investment

Vacuum furnaces and the associated high-purity pumping systems represent a significant capital expense. This makes the process more costly upfront than many other joining methods.

Process Sensitivity

The quality of the final joint is highly sensitive to process variables. Improper cleaning, poor part fit-up, or incorrect thermal profiles can easily lead to failed parts. Success demands strict process control.

Batch Processing Limitations

Vacuum brazing is a batch process. Loading, pumping down the vacuum, running the thermal cycle, and cooling can take several hours. It is not well-suited for high-speed, single-piece flow production.

Making the Right Choice for Your Application

Use these guidelines to determine if vacuum brazing is the right fit for your project.

- If your primary focus is maximum joint strength and cleanliness: Vacuum brazing is superior, as it creates oxide-free, flux-free joints with parent-metal-like strength.

- If your primary focus is joining complex geometries or dissimilar materials: The process is exceptionally well-suited for intricate assemblies and bonding materials like metals to ceramics.

- If your primary focus is cost-sensitive, high-volume production of simple parts: You should carefully evaluate if the performance benefits justify the higher cost and slower cycle times compared to torch brazing or welding.

By understanding these core principles, you can confidently determine when this advanced technique is the optimal solution for your engineering challenge.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | High-purity joining in vacuum furnace using filler metal below base material melting points |

| Key Steps | 1. Cleaning and assembly 2. Controlled heating in vacuum 3. Brazing temperature (above filler liquidus) 4. Capillary action fills joint 5. Controlled cooling |

| Advantages | No oxidation or flux, strong joints, suitable for complex geometries and dissimilar materials |

| Limitations | High initial cost, process sensitivity, batch processing not ideal for high-volume production |

| Applications | Ideal for maximum strength, cleanliness, and joining metals to ceramics or intricate parts |

Ready to enhance your laboratory's capabilities with precision vacuum brazing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet unique experimental requirements. Whether you're working with complex assemblies or dissimilar materials, our expertise ensures clean, strong joints without flux. Contact us today to discuss how we can support your projects with reliable, high-performance equipment!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering