By creating a pristine environment free of contaminants, vacuum sintering fundamentally improves material properties through three primary actions. It prevents the formation of oxide films that hinder bonding, removes trapped gases to achieve near-total density, and allows for the formation of a highly refined and uniform internal microstructure, which is the foundation of superior strength and performance.

Vacuum sintering is not merely a heating process; it is a purification and structural refinement technique. It transforms a porous powder compact into a dense, high-performance solid by controlling the material's environment on a molecular level.

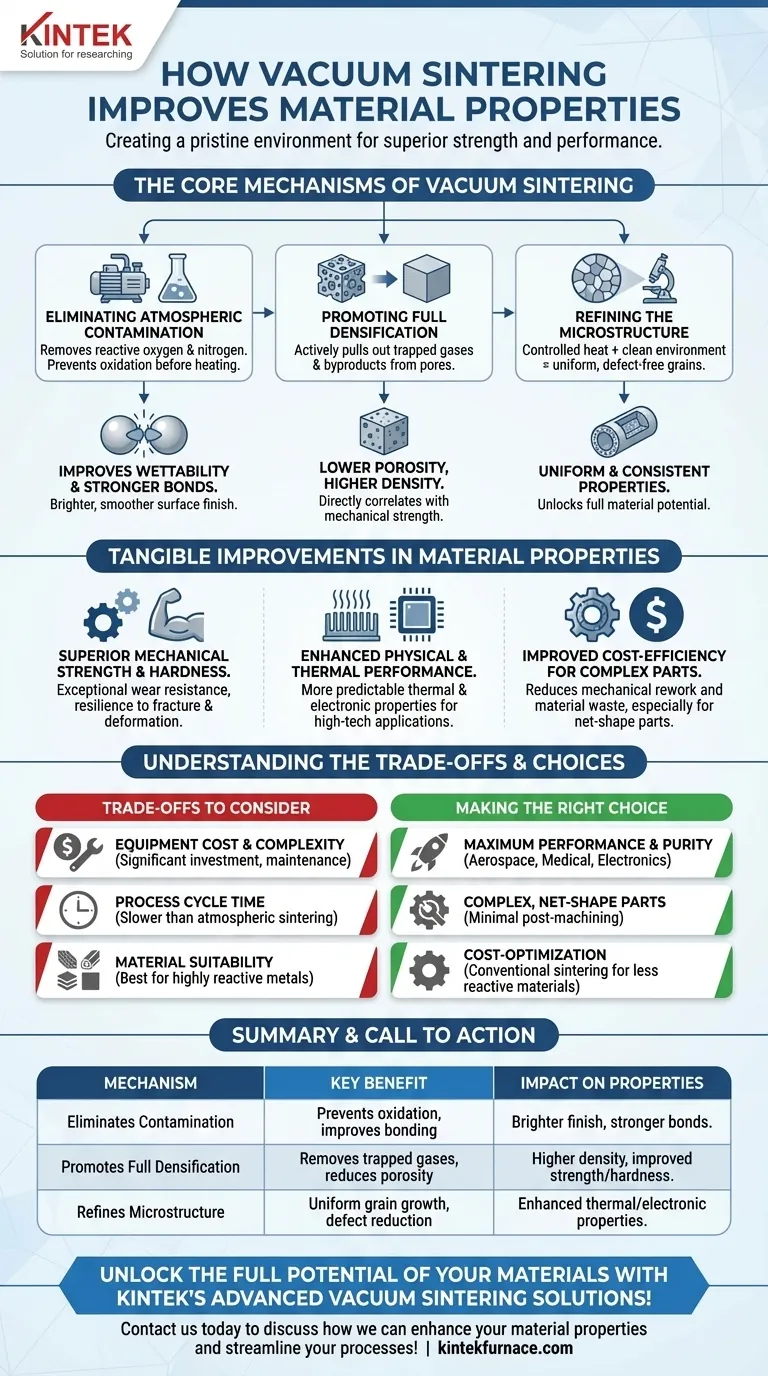

The Core Mechanisms of Vacuum Sintering

To understand the benefits of vacuum sintering, you must first understand the problems it solves. Traditional sintering in an open atmosphere introduces contaminants—primarily oxygen and nitrogen—that compromise the final material's integrity.

Eliminating Atmospheric Contamination

During heating, metal powders are highly reactive. The vacuum environment removes the air, preventing oxidation before the material reaches its sintering temperature.

This accomplishes two things. First, it ensures that no oxide films form on the surfaces of the powder particles. These films act as barriers, improving the wettability between particles and allowing for a stronger metallic bond to form.

Second, the lack of oxidation results in a brighter, smoother surface finish on the final part, often reducing or eliminating the need for secondary mechanical cleaning or polishing.

Promoting Full Densification

A block of pressed powder, known as a "green part," contains a significant volume of trapped gas within its pores. During atmospheric sintering, this gas can become trapped, leading to residual porosity.

Vacuum sintering actively pulls these gases out of the material. This promotes the escape of gaseous byproducts and dissolved gases from deep within the part's structure.

The result is a component with significantly lower porosity and higher density. Since density is directly correlated with mechanical strength, this is one of the most critical benefits of the process.

Refining the Microstructure

The combination of controlled heat and a clean environment allows for the formation of a uniform and defect-free microstructure. Without unwanted chemical reactions occurring, the material's grains can grow and bond in a predictable and optimal way.

This structural refinement is what unlocks the material's full potential, ensuring that properties like hardness and strength are consistent throughout the entire component.

Tangible Improvements in Material Properties

The underlying mechanisms of vacuum sintering translate directly into measurable performance gains in the finished product.

Superior Mechanical Strength and Hardness

By eliminating internal voids and ensuring strong inter-particle bonds, vacuum sintering produces parts with exceptional strength, hardness, and wear resistance. The refined microstructure makes the material more resilient to fracture and deformation.

Enhanced Physical and Thermal Performance

Higher density does more than improve strength. It also enhances other physical characteristics, leading to more predictable thermal and electronic properties. This is critical for components used in high-performance electronic or thermal management applications.

Improved Cost-Efficiency for Complex Parts

While the equipment can be expensive, the process can reduce overall costs. By producing parts with excellent surface quality, the need for mechanical rework is minimized.

This is especially true for small or complex net-shape parts, where vacuum sintering can produce a finished component with high precision, reducing material waste and downstream machining labor.

Understanding the Trade-offs

While powerful, vacuum sintering is a specialized process with specific considerations. It is not a universal replacement for all heat treatments.

Equipment Cost and Complexity

Vacuum furnaces and their associated pumping systems represent a significant capital investment compared to conventional atmospheric furnaces. They also require more sophisticated operation and maintenance.

Process Cycle Time

Achieving a high vacuum and executing the controlled heating and cooling profiles can be a time-consuming process. For high-volume production of simple parts, this can make it less economical than faster, atmospheric alternatives.

Material Suitability

The benefits of vacuum sintering are most pronounced for materials that are highly reactive with oxygen, such as titanium, refractory metals, and certain stainless steels. For materials that are less sensitive to atmospheric contamination, the added process complexity may not be justified.

Making the Right Choice for Your Application

Selecting the right sintering process requires aligning the method's capabilities with your project's end goals.

- If your primary focus is maximum performance and purity: Vacuum sintering is the superior choice for reactive metals or for applications in aerospace, medical, or electronics where material integrity is non-negotiable.

- If your primary focus is creating complex, net-shape parts: This process excels at producing high-density, intricate components that require minimal post-machining, saving on labor and material waste.

- If your primary focus is cost-optimization for non-critical parts: For less reactive materials where ultimate density is not the goal, conventional atmospheric sintering often provides a more economical path.

Ultimately, choosing vacuum sintering is a strategic decision to prioritize the absolute integrity and performance of the final material.

Summary Table:

| Mechanism | Key Benefit | Impact on Material Properties |

|---|---|---|

| Eliminates atmospheric contamination | Prevents oxidation and improves bonding | Brighter surface finish, stronger metallic bonds |

| Promotes full densification | Removes trapped gases and reduces porosity | Higher density, improved mechanical strength and hardness |

| Refines microstructure | Allows uniform grain growth and defect reduction | Enhanced thermal and electronic properties, consistent performance |

Unlock the full potential of your materials with KINTEK's advanced vacuum sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, and more. Our deep customization capability ensures precise alignment with your unique experimental needs, delivering superior strength, purity, and cost-efficiency for complex parts. Contact us today to discuss how we can enhance your material properties and streamline your processes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures