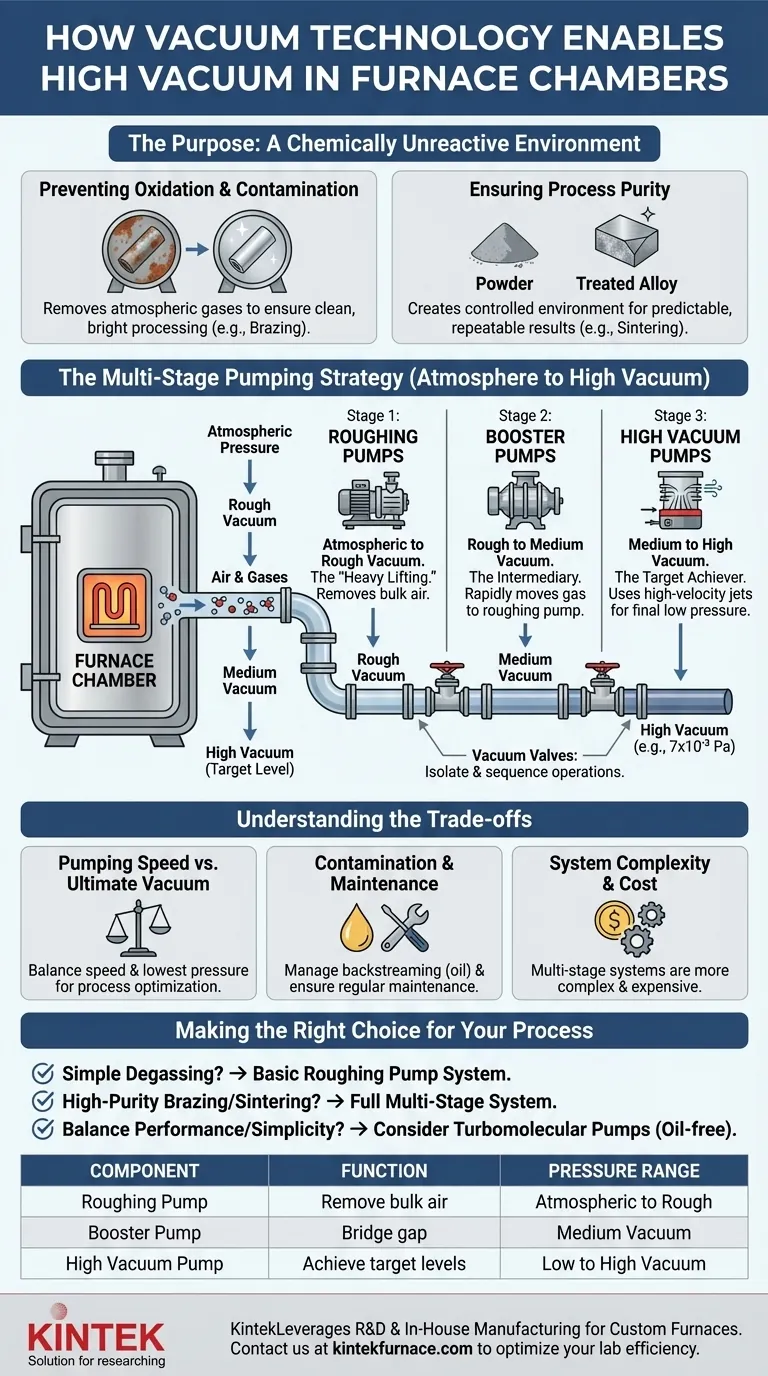

At its core, vacuum technology enables high vacuum conditions in furnaces by using a coordinated, multi-stage pumping system. This system progressively removes air and other gases from a sealed chamber, with different types of pumps working in sequence to efficiently lower the pressure from atmospheric levels down to a near-perfect vacuum.

The central principle is that no single pump can operate efficiently across the entire pressure range from atmosphere to high vacuum. A sequence of roughing, booster, and high-vacuum pumps is required, each optimized for a specific pressure regime, to systematically evacuate the furnace chamber.

The Purpose of a Vacuum Environment

Before examining the hardware, it's crucial to understand why a vacuum is necessary in high-temperature applications. The primary goal is to create a chemically unreactive environment.

Preventing Oxidation and Contamination

At elevated temperatures, most materials—especially metals—readily react with oxygen and other atmospheric gases. This results in oxidation (rusting or scaling) and the formation of other undesirable compounds, compromising the material's integrity and surface finish.

By removing the atmosphere, a vacuum furnace eliminates the reactants. This allows for clean, bright processing of parts without contamination, which is critical for applications like brazing and medical implant manufacturing.

Ensuring Process Purity

Many advanced material processes, such as sintering powdered metals or heat-treating sensitive alloys, require an extremely controlled environment. A high vacuum ensures that the only interactions occurring are the ones intended by the process, leading to predictable and repeatable results.

The Multi-Stage Pumping Strategy

Achieving a high vacuum, such as 7×10⁻³ Pa, is a journey through different orders of magnitude of pressure. This journey is managed by a sequence of specialized pumps.

Stage 1: Roughing Pumps

The process begins with roughing pumps, typically mechanical or rotary pumps. Their job is to do the initial "heavy lifting."

These pumps physically remove the bulk of the air from the chamber, taking the pressure from atmospheric levels down to a rough vacuum. They are effective at moving large volumes of gas but lose efficiency at lower pressures.

Stage 2: Booster Pumps

Once the roughing pump's effectiveness wanes, a booster pump (often a Roots pump) takes over. This pump cannot exhaust directly to the atmosphere; it must be backed by the roughing pump.

The Roots pump acts as an intermediary, rapidly moving gas from the furnace chamber to the roughing pump. It excels in the medium vacuum range, bridging the performance gap between the roughing and high-vacuum stages.

Stage 3: High Vacuum Pumps

For the final stage, a diffusion pump is engaged. This pump is responsible for achieving the target high vacuum level.

A diffusion pump operates on a different principle: it uses high-velocity jets of oil vapor to knock gas molecules down toward its outlet, where they are removed by the backing pump system. Diffusion pumps only function effectively once the pressure is already quite low, which is why the preceding stages are essential.

The Role of Vacuum Valves

The entire system is interconnected with a series of vacuum valves. These valves are critical for isolating different parts of the system, allowing the pumps to be brought online sequentially and protecting the chamber from any potential backflow from the pumps.

Understanding the Trade-offs

While powerful, vacuum systems come with inherent complexities and operational considerations that must be managed.

Pumping Speed vs. Ultimate Vacuum

There is a fundamental trade-off between how fast a system can evacuate a chamber (pumping speed) and the lowest pressure it can achieve (ultimate vacuum). The combination of different pumps is designed to optimize this balance for a specific furnace volume and process cycle time.

Contamination and Maintenance

Diffusion pumps use oil, which can migrate back into the furnace chamber—a phenomenon called backstreaming—if the system is not properly designed with baffles and traps. This oil vapor can contaminate the parts being processed.

Furthermore, all mechanical pumps require regular maintenance, such as oil changes, to ensure reliability and performance. Neglecting this can lead to system failure and costly downtime.

System Complexity and Cost

A multi-stage high-vacuum system is significantly more complex and expensive to build and operate than a simple roughing pump setup. The inclusion of booster pumps, diffusion pumps, sophisticated valves, and control systems adds layers of cost and potential points of failure.

Making the Right Choice for Your Process

The required vacuum level is dictated entirely by the sensitivity of your materials and process.

- If your primary focus is simple degassing or low-temperature annealing: A basic system with only a mechanical roughing pump may be sufficient to remove the bulk of the atmosphere.

- If your primary focus is high-purity brazing, sintering, or heat-treating sensitive alloys: A full multi-stage system with roughing, booster, and diffusion pumps is non-negotiable to prevent oxidation and ensure process integrity.

- If your primary focus is balancing performance with operational simplicity: Modern systems may substitute a turbomolecular pump for a diffusion pump, offering a cleaner (oil-free) high-vacuum solution, albeit often at a different cost and maintenance profile.

Understanding the role of each component in the vacuum system empowers you to control your process environment with precision.

Summary Table:

| Component | Function | Pressure Range |

|---|---|---|

| Roughing Pump | Removes bulk air from chamber | Atmospheric to rough vacuum |

| Booster Pump | Bridges gap between roughing and high-vacuum stages | Medium vacuum |

| High Vacuum Pump | Achieves target high vacuum levels | Low to high vacuum |

| Vacuum Valves | Isolates system parts for sequential operation | All stages |

Ready to elevate your material processing with reliable high-vacuum furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems, tailored to your unique needs through deep customization. Whether you're in brazing, sintering, or heat-treating sensitive alloys, our expertise ensures precise, contamination-free results. Contact us today to discuss how we can optimize your laboratory's efficiency and performance!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density