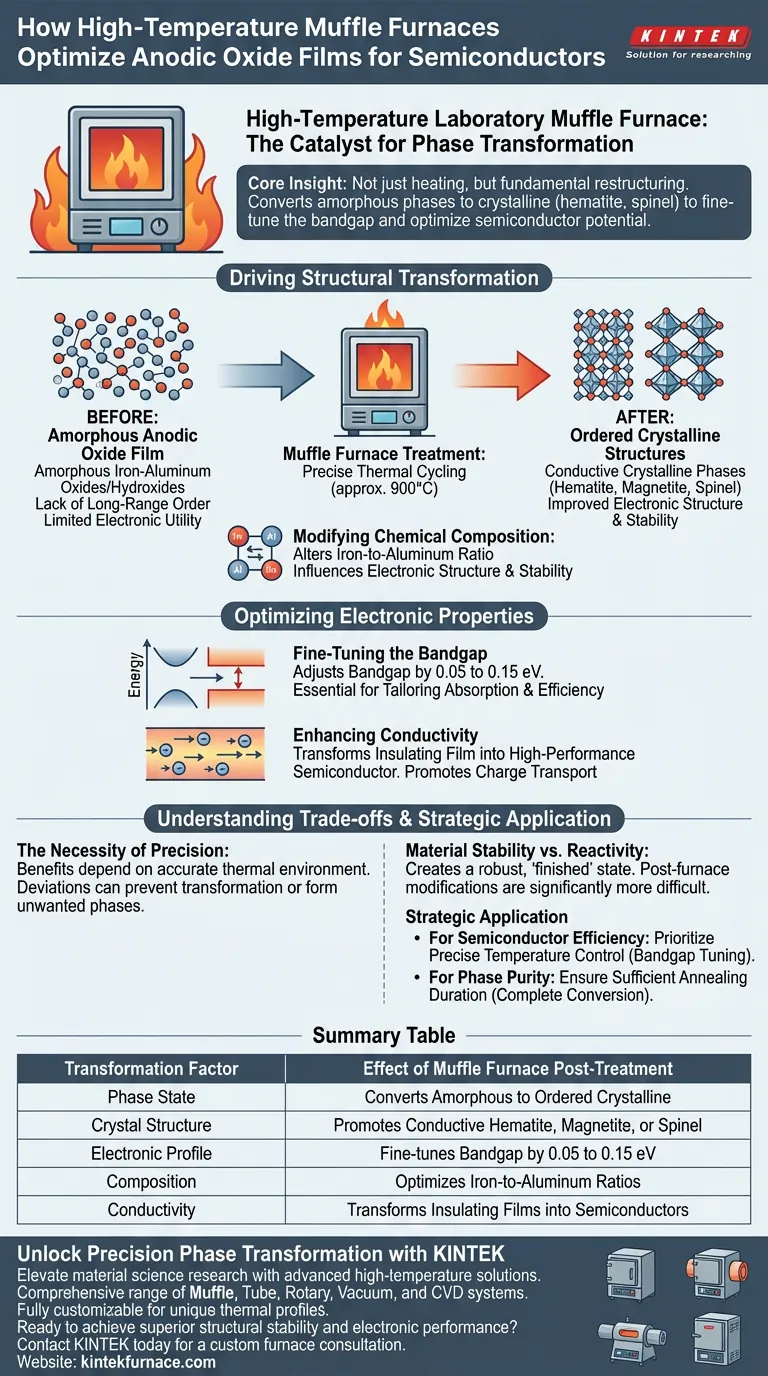

The primary function of a high-temperature laboratory muffle furnace in this context is to act as a precise mechanism for phase transformation. By creating a controlled thermal annealing environment—specifically at temperatures around 900°C—the furnace drives the conversion of amorphous iron-aluminum oxides into ordered, conductive crystalline structures.

Core Insight A muffle furnace does not merely heat the material; it fundamentally restructures it. By converting amorphous phases into crystalline ones like hematite or spinel, the furnace allows for the precise fine-tuning of the oxide film's bandgap, directly optimizing its potential as a semiconductor.

Driving Structural Transformation

From Amorphous to Crystalline

Initially, anodic oxide films often exist as amorphous iron-aluminum oxides or hydroxides. These structures lack long-range order, which limits their electronic utility.

The muffle furnace provides the high thermal energy required to overcome the activation barrier for crystallization.

This thermal cycling drives the material to reorganize into stable, conductive crystalline phases, such as hematite, magnetite, or spinel.

Modifying Chemical Composition

Beyond simple crystallization, the furnace environment facilitates changes in the material's stoichiometry.

The treatment modifies the iron-to-aluminum ratio within the film.

This compositional shift is critical because the ratio of these metals directly influences the electronic structure and stability of the final oxide layer.

Optimizing Electronic Properties

Fine-Tuning the Bandgap

The most critical outcome of this post-treatment is the ability to adjust the material's bandgap value.

Through precise thermal cycling, researchers can shift the bandgap by 0.05 to 0.15 eV.

This adjustment is essential for tailoring the material's absorption properties and efficiency for specific semiconductor applications.

Enhancing Conductivity

The shift from amorphous to crystalline phases inherently improves charge transport.

By forming phases like magnetite and spinel, the furnace treatment transforms a relatively insulating film into one with superior semiconductor characteristics.

Understanding the Trade-offs

The Necessity of Precision

The benefits of this process are entirely dependent on the accuracy of the thermal environment.

If the temperature deviates significantly from the target (e.g., 900°C), the desired phase transformation may not occur, or unwanted phases may form.

Material Stability vs. Reactivity

While high-temperature treatment stabilizes the crystalline structure, it fundamentally alters the material's reactivity.

The process creates a robust, "finished" state, meaning post-furnace modifications to the film's structure become significantly more difficult.

Strategic Application for Material Design

To maximize the utility of your anodic oxide films, align your furnace parameters with your specific end-goals.

- If your primary focus is Semiconductor Efficiency: Prioritize precise temperature control to fine-tune the bandgap within the 0.05–0.15 eV window.

- If your primary focus is Phase Purity: Ensure the annealing duration is sufficient to fully convert amorphous hydroxides into crystalline hematite or spinel.

Ultimately, the muffle furnace is the bridge between a raw chemical film and a functional electronic component.

Summary Table:

| Transformation Factor | Effect of Muffle Furnace Post-Treatment |

|---|---|

| Phase State | Converts amorphous oxides/hydroxides into ordered crystalline phases |

| Crystal Structure | Promotes formation of conductive Hematite, Magnetite, or Spinel |

| Electronic Profile | Fine-tunes bandgap values by 0.05 to 0.15 eV |

| Composition | Optimizes iron-to-aluminum ratios for better stoichiometry |

| Conductivity | Transforms insulating films into high-performance semiconductors |

Unlock Precision Phase Transformation with KINTEK

Elevate your material science research with KINTEK’s advanced high-temperature solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are fine-tuning bandgap values for semiconductors or driving complex crystallization in oxide films, our laboratory furnaces are fully customizable to meet your unique thermal profiles.

Ready to achieve superior structural stability and electronic performance?

Contact KINTEK today for a custom furnace consultation

Visual Guide

References

- Rubén del Olmo, Marta Michalska-Domańska. Anodization of FeAl Alloy in Boric-Sulfuric Acid: Band Gap Tuning Via Copper Doping and Annealing. DOI: 10.1007/s11661-025-07914-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What key technologies were utilized in the muffle furnace for environmental sample analysis? Unlock Precise Pollutant Detection

- What are the advantages of using a muffle furnace for catalyst recalcination? Achieve Full Structural Regeneration

- What role does a muffle furnace play in NHoHMM fabrication? Mastering Precision Solid-State Dewetting

- What safety measures should be followed when using a muffle furnace? Essential Steps for Safe Operation

- How does a laboratory drying oven facilitate moisture removal? Achieve Precise Data with KINTEK Drying Solutions

- What role does a Muffle Furnace play in biomass pellet torrefaction? Optimize Your High-Temperature Processing

- What scientific processes can a muffle furnace assist with? Unlock Precise, Contaminant-Free Heat Treatment

- What are the differences in insulation between muffle furnaces and drying ovens? Key Design Insights for Your Lab