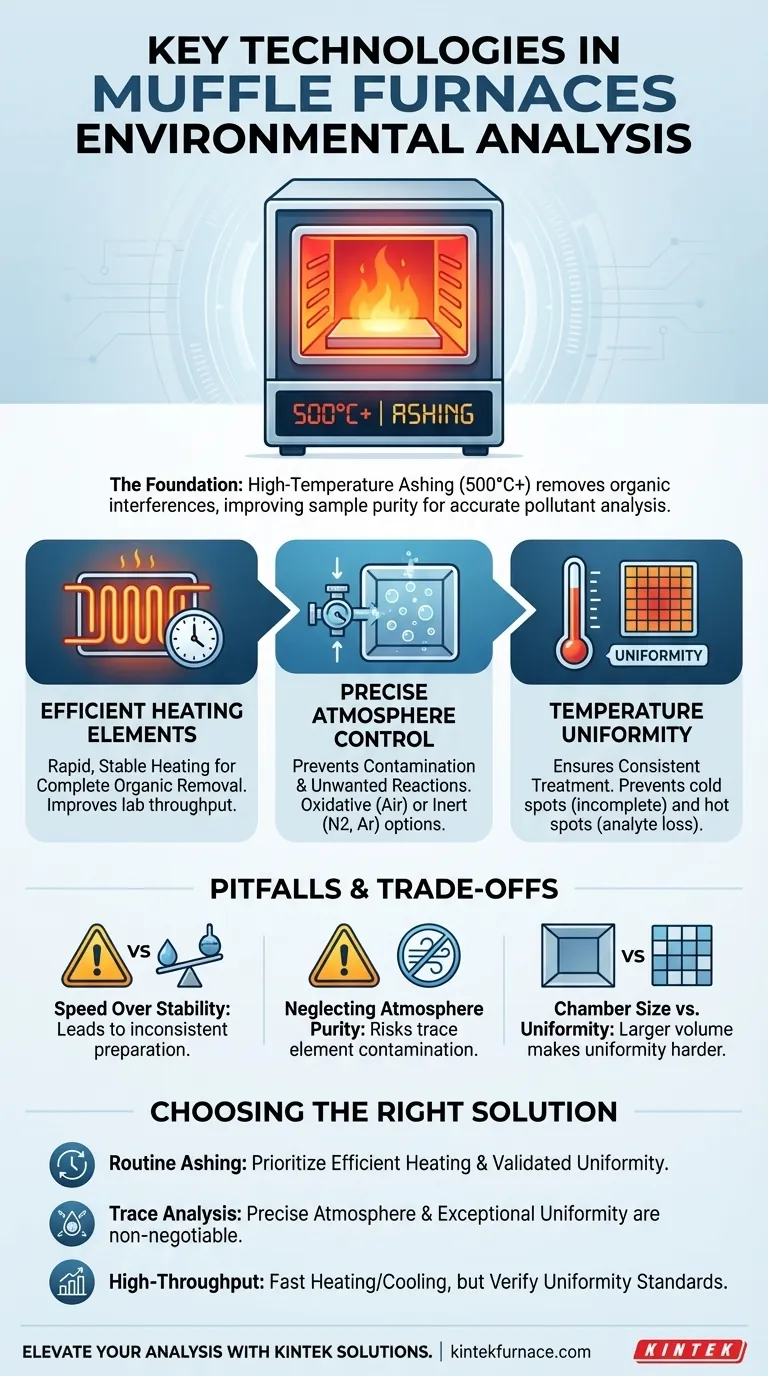

At its core, a muffle furnace optimized for environmental analysis relies on three fundamental technologies. These are efficient heating elements, precise atmosphere control, and superior temperature uniformity. Together, they ensure that environmental samples are prepared consistently and without contamination, which is the necessary foundation for accurate pollutant analysis.

The true value of these technologies is not just heating a sample, but creating a perfectly controlled thermal environment. This control is what isolates the target analytes by systematically removing interferences, directly leading to more reliable and accurate analytical results.

The Foundation: Why Thermal Treatment is Critical

Environmental samples from soil, water, or industrial sites are complex mixtures. They often contain organic substances that interfere with the accurate measurement of inorganic pollutants like heavy metals.

The primary function of the muffle furnace in this context is to remove these organic interferences through a high-temperature process, often called ashing.

The 500°C Threshold

To be effective, the furnace must operate at temperatures above 500°C. This ensures the complete combustion and removal of organic compounds that would otherwise skew the results of subsequent analysis.

By cleanly removing this organic matrix, the purity of the sample is significantly increased. This leaves behind the inorganic components of interest for a much more accurate measurement.

A Breakdown of the Core Technologies

Achieving this clean, high-temperature treatment requires a synergistic combination of technologies. Each one solves a specific problem related to sample integrity and analytical accuracy.

Efficient Heating Elements

The first key technology is a system of high-efficiency heating elements. Their purpose is to bring the furnace chamber to the target temperature quickly and stably.

This reduces sample processing time, improving lab throughput. More importantly, it ensures the furnace can reliably reach and hold the necessary temperature for complete removal of organic matter.

Precise Atmosphere Control

The atmosphere inside the furnace has a direct impact on the sample. Precise atmosphere control allows the operator to dictate the chemical environment during heating.

This may involve using an oxidative atmosphere (like air) to intentionally burn away organics. Alternatively, an inert atmosphere (like nitrogen or argon) can be used to heat the sample without causing unwanted chemical reactions, preserving the sample's original state minus the volatile components. This control is vital for sample purity.

Temperature Uniformity

Perhaps the most critical factor for data quality is temperature uniformity. This ensures that the temperature is consistent across the entire furnace chamber.

Without uniformity, some parts of the sample may experience "cold spots," leading to incomplete treatment. Other areas could suffer from "hot spots," which might cause the target analytes to degrade or volatilize, resulting in an underestimation of the pollutant levels. Even heating guarantees that every part of every sample receives the exact same treatment.

Understanding the Trade-offs and Pitfalls

While these technologies are essential, their implementation involves balancing competing priorities. Misunderstanding these trade-offs can compromise your results.

Pitfall 1: Prioritizing Speed Over Stability

A furnace that heats rapidly but cannot hold a stable and uniform temperature is counterproductive. The goal is not just to get hot, but to maintain a precisely controlled thermal condition. Unstable temperatures lead to inconsistent sample preparation and unreliable data.

Pitfall 2: Neglecting Atmosphere Purity

Assuming the ambient lab air is a sufficient atmosphere can be a mistake. For highly sensitive trace element analysis, even minor components in the air can react with or contaminate the sample. Using a controlled, purified atmosphere provides an essential layer of security for your results.

Pitfall 3: Ignoring Chamber Size vs. Uniformity

A larger furnace chamber allows for higher throughput by processing more samples at once. However, achieving perfect temperature uniformity becomes significantly more challenging as the volume increases. There is a direct trade-off between batch size and the guarantee of uniform treatment.

Making the Right Choice for Your Goal

The emphasis you place on each technology should depend directly on your specific analytical requirements.

- If your primary focus is routine ashing for organic removal: Prioritize a furnace with efficient heating and validated temperature uniformity to ensure consistent results.

- If your primary focus is trace element or sensitive pollutant analysis: Precise atmosphere control and exceptional temperature uniformity are non-negotiable to prevent sample contamination and analyte loss.

- If your primary focus is high-throughput screening: Look for systems with fast heating and cooling cycles, but demand verification that temperature uniformity meets the minimum standard required for your data quality objectives.

Ultimately, selecting the right muffle furnace is about mastering the thermal environment to guarantee the integrity of your analytical data.

Summary Table:

| Technology | Key Benefit |

|---|---|

| Efficient Heating Elements | Rapid, stable heating for complete organic removal |

| Precise Atmosphere Control | Prevents contamination and unwanted reactions |

| Temperature Uniformity | Ensures consistent sample treatment and data accuracy |

Elevate your environmental analysis with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing accuracy and efficiency in pollutant detection. Contact us today to discuss how we can support your lab's goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals