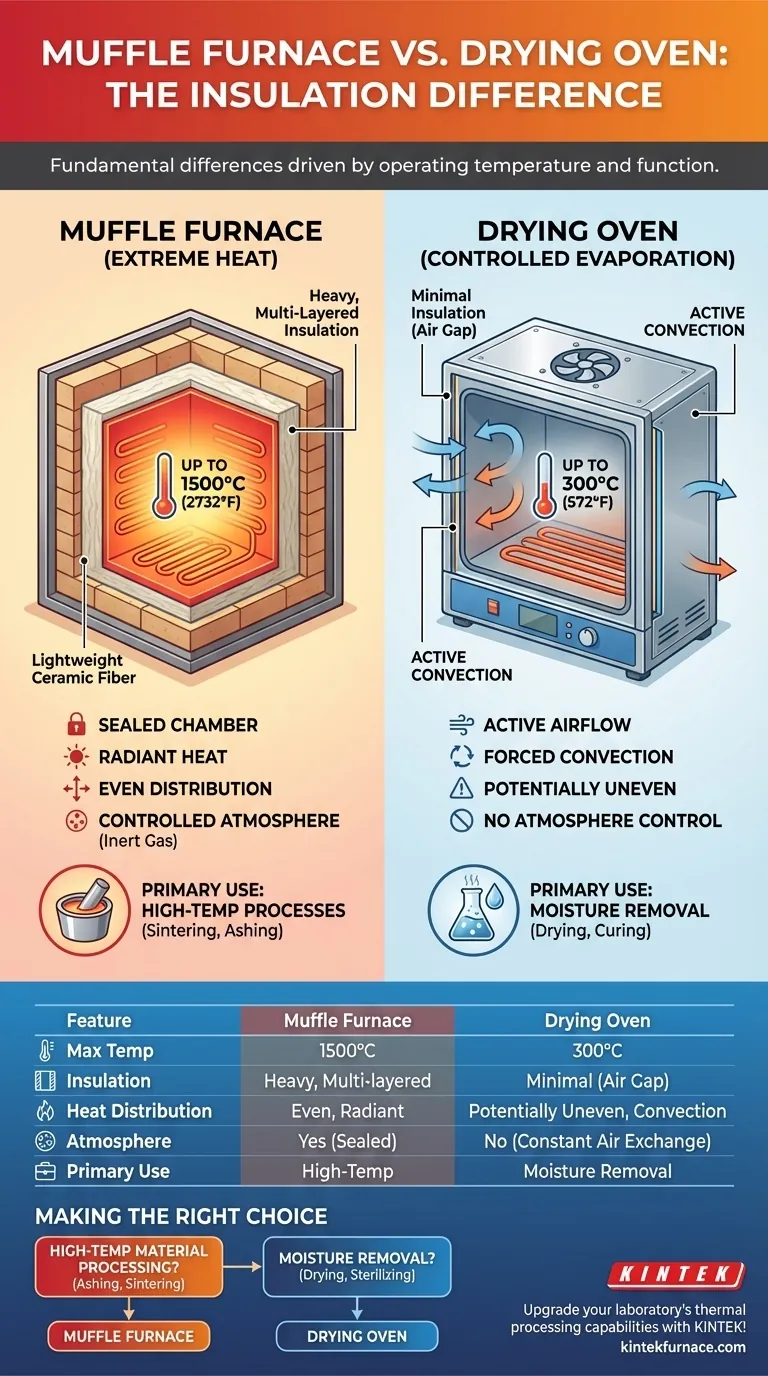

The fundamental difference in insulation between muffle furnaces and drying ovens is a direct result of their vastly different purposes and operating temperatures. Muffle furnaces are built with heavy, multi-layered insulation to safely contain extreme heat (up to 1500°C), while drying ovens use minimal insulation because they operate at much lower temperatures (around 300°C) and require a different thermal mechanism.

The choice between a muffle furnace and a drying oven is not about which is "better," but about selecting the right tool for the job. A furnace is designed for high-temperature material transformation in a sealed environment, whereas an oven is designed for low-temperature moisture removal via active airflow. Their insulation strategies reflect this core functional divide.

The Role of Temperature and Heat Containment

The most significant factor driving the design of these two instruments is their intended temperature range. This single parameter dictates everything from insulation material to cost.

Muffle Furnaces: For Extreme Temperatures

A muffle furnace is engineered to reach and maintain extremely high temperatures, often up to 1500°C (2732°F) or higher.

To achieve this safely and efficiently, they require heavy, multi-layered insulation. This typically consists of dense refractory ceramic bricks and lightweight ceramic fiber. This robust insulation is critical for protecting the user and the surrounding environment, minimizing energy loss, and ensuring stable, uniform heat.

Drying Ovens: For Controlled Evaporation

A drying oven operates at significantly lower temperatures, usually capping out around 300°C (572°F). Its primary goal is not to transform a material with heat, but to remove moisture from it.

Because of this lower thermal demand, drying ovens feature minimal insulation. A simple air gap between double steel walls is often sufficient. Heavy insulation would be unnecessary, costly, and counterproductive to its function, which relies on air exchange.

How Design Dictates Function

The insulation is just one piece of a larger design philosophy. The internal mechanics of how each device manages heat are fundamentally different.

The Sealed Chamber vs. Active Airflow

A muffle furnace is essentially a sealed box. During operation, its chamber is isolated from the outside air. Heat is distributed primarily through radiation from electric heating elements embedded in the walls, creating a very stable, still environment.

A drying oven, by contrast, is an active convection system. It continuously draws in fresh air, passes it over a heating element, and circulates it through the chamber with a fan. This heated air absorbs moisture from the samples and is then vented out, carrying the moisture with it.

The Impact on Heat Uniformity

The sealed, radiant design of a muffle furnace results in exceptionally even heat distribution. The lack of airflow prevents the creation of hot and cold spots, which is critical for sensitive processes like sintering or chemical analysis.

While a drying oven's fan is intended to create a uniform temperature, the nature of forced convection in a large chamber can often lead to uneven heating. The areas closest to the fan or heating element may be hotter than corners or obstructed areas.

Atmosphere Control

The sealed design of a muffle furnace allows for controlled atmospheres. By purging the chamber and introducing an inert gas like nitrogen or argon, users can prevent oxidation and perform processes that are impossible in open air. This is a key function for many metallurgical and chemical applications.

A drying oven cannot control its atmosphere because it is, by design, constantly exchanging its internal volume with the surrounding air.

Understanding the Trade-offs

Choosing the wrong instrument can lead to failed processes, damaged equipment, or inaccurate results. Understanding their limitations is as important as knowing their capabilities.

The Cost of High-Heat Capability

The robust insulation, high-temperature heating elements, and precise controllers required for a muffle furnace make it a significantly more expensive piece of equipment than a drying oven.

The Limits of Convection Drying

Drying ovens are purpose-built for removing moisture and are not suitable for high-temperature applications. Their temperature inaccuracy and lack of atmosphere control make them unusable for most material science or analytical chemistry work.

Why You Can't Efficiently "Dry" in a Furnace

While a muffle furnace can certainly make things hot, it is a poor choice for drying. Its sealed chamber traps any moisture released from a sample. This water vapor has no way to escape, dramatically slowing the drying process and potentially creating a high-pressure steam environment.

Making the Right Choice for Your Application

Your final decision must be based on the specific thermal process you need to perform.

- If your primary focus is high-temperature material processing, such as ashing, sintering, annealing, or heat-treating metals, the muffle furnace is your only option.

- If your primary focus is removing moisture from samples, sterilizing glassware, or curing coatings at low to moderate temperatures, the drying oven is the correct, efficient, and cost-effective tool.

- If your primary focus is absolute temperature uniformity and stability for a sensitive process (even at lower temperatures), the sealed, radiant environment of a muffle furnace offers superior performance.

By understanding these core design principles, you can confidently select the right thermal processing tool for your specific scientific or industrial goal.

Summary Table:

| Feature | Muffle Furnace | Drying Oven |

|---|---|---|

| Max Temperature | Up to 1500°C | Up to 300°C |

| Insulation Type | Heavy, multi-layered (ceramic bricks/fiber) | Minimal (air gap between walls) |

| Heat Distribution | Even, via radiation | Potentially uneven, via forced convection |

| Atmosphere Control | Yes, sealed chamber allows inert gases | No, constant air exchange |

| Primary Use | High-temperature processes (e.g., sintering, ashing) | Moisture removal, low-temperature drying |

Upgrade your laboratory's thermal processing capabilities with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for insulation, temperature control, and efficiency. Don't settle for less—contact us today to discuss how our solutions can enhance your research and industrial processes!

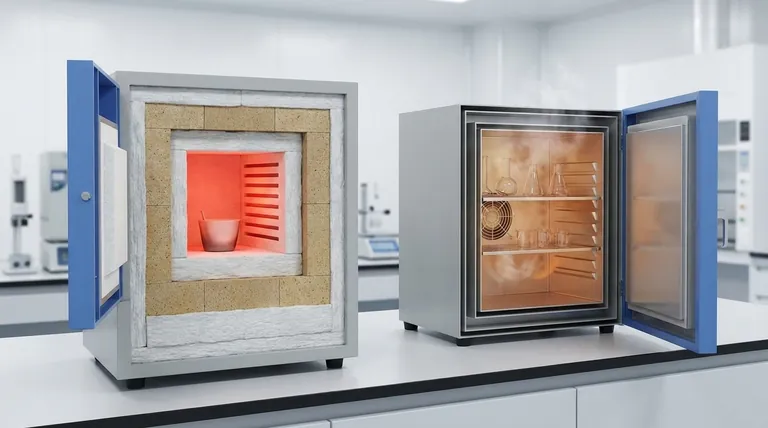

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO