A muffle furnace acts as the precision thermal chamber essential for the self-assembly phase of Nanosphere-on-Hyperbolic Metamaterial (NHoHMM) fabrication. It provides a strictly controlled environment to heat multilayer structures containing thin silver films (approximately 5nm) to 300°C, triggering the physical transformation of the metal layers.

The muffle furnace facilitates the critical process of solid-state dewetting, where continuous silver films break apart and self-assemble into dispersed nanospheres. This transformation is fundamental to creating the localized surface plasmon resonance (LSPR) properties required for optical metamaterials.

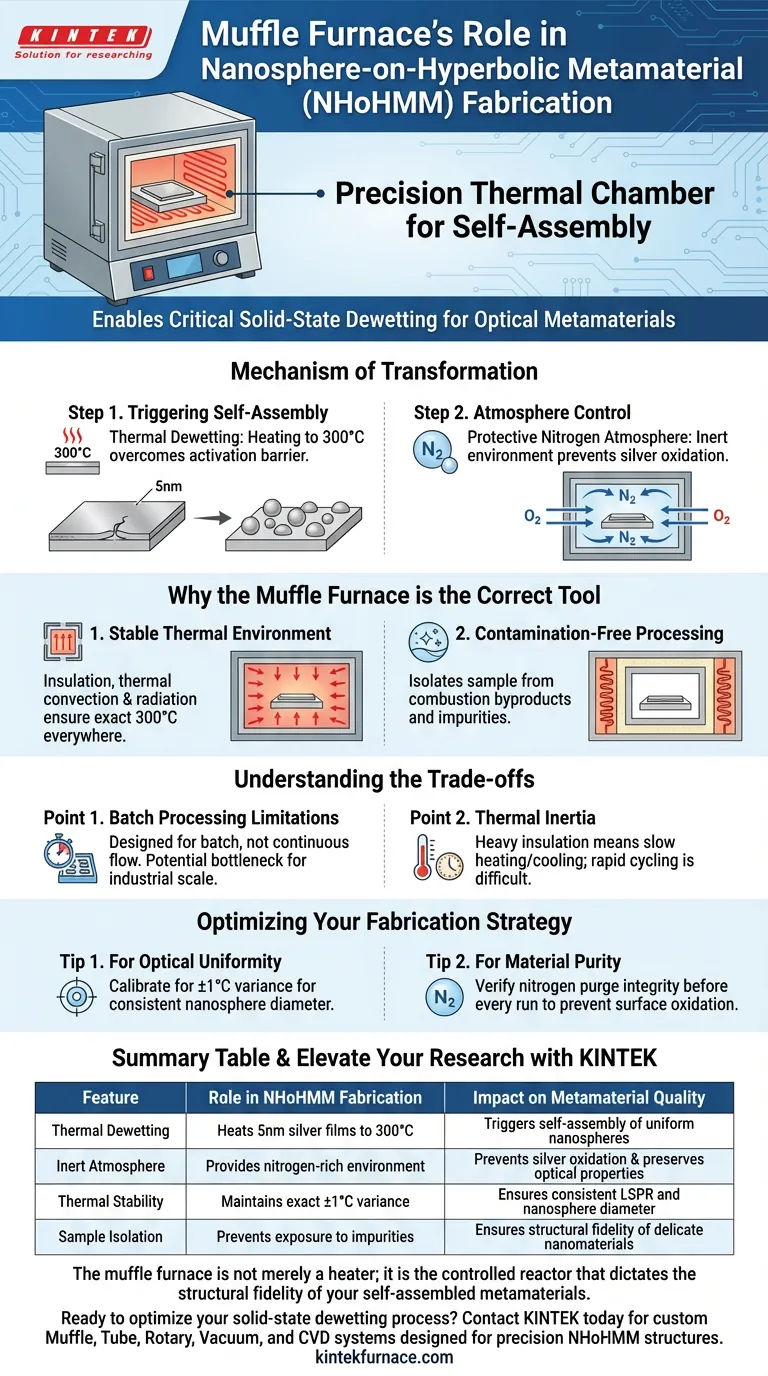

The Mechanism of Transformation

Triggering Self-Assembly

The primary function of the muffle furnace in this context is to induce thermal dewetting.

By heating the substrate to 300°C, the furnace adds enough energy to the system to overcome the activation barrier of the thin silver film.

This causes the continuous 5nm layer to rupture and reorganize into isolated, spherical islands (nanospheres) to minimize surface energy.

Atmosphere Control

The furnace maintains a protective nitrogen atmosphere during the heating process.

This inert environment is vital because silver is highly reactive to oxygen at elevated temperatures.

Without this protective gas flow, the silver would oxidize rather than dewet cleanly, destroying the optical properties of the final metamaterial.

Why the Muffle Furnace is the Correct Tool

Stable Thermal Environment

Success in NHoHMM fabrication requires absolute temperature stability to ensure uniform nanosphere size distribution.

Muffle furnaces utilize insulating materials to prevent heat loss and combine thermal convection and radiation to distribute heat evenly.

This ensures that every part of the sample experiences the exact same 300°C condition, preventing gradients that would lead to irregular structures.

Contamination-Free Processing

Unlike direct-flame heating methods, a muffle furnace isolates the sample from combustion byproducts.

The heating coils are separated from the chamber or embedded in insulation, ensuring the heat source does not introduce impurities.

This contamination-free environment is critical for nanomaterials, where even microscopic impurities can disrupt the delicate LSPR effects.

Understanding the Trade-offs

Batch Processing Limitations

Muffle furnaces are inherently designed for batch processing, not continuous flow manufacturing.

While excellent for research and high-precision fabrication, this can become a bottleneck if you are attempting to scale production to industrial levels.

Thermal Inertia

These furnaces rely on heavy insulation to maintain stability, which results in significant thermal inertia.

This means heating up and cooling down takes time; rapid temperature cycling is generally not possible.

If your process requires immediate quenching after dewetting, you must account for the time required to safely remove the sample from the hot chamber.

Optimizing Your Fabrication Strategy

To ensure high-quality NHoHMM structures, align your furnace usage with your specific technical goals:

- If your primary focus is optical uniformity: Ensure your furnace is calibrated to maintain 300°C with less than ±1°C variance to guarantee consistent nanosphere diameter across the sample.

- If your primary focus is material purity: Verify the integrity of the nitrogen purge system before every run to prevent surface oxidation of the silver layer.

The muffle furnace is not merely a heater; it is the controlled reactor that dictates the structural fidelity of your self-assembled metamaterials.

Summary Table:

| Feature | Role in NHoHMM Fabrication | Impact on Metamaterial Quality |

|---|---|---|

| Thermal Dewetting | Heats 5nm silver films to 300°C | Triggers self-assembly of uniform nanospheres |

| Inert Atmosphere | Provides nitrogen-rich environment | Prevents silver oxidation and preserves optical properties |

| Thermal Stability | Maintains exact ±1°C variance | Ensures consistent LSPR and nanosphere diameter |

| Sample Isolation | Prevents exposure to combustion/impurities | Ensures structural fidelity of delicate nanomaterials |

Elevate Your Nanomaterial Research with KINTEK

Precision is the heartbeat of metamaterial fabrication. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to provide the stable thermal environments and atmosphere control required for complex NHoHMM structures. Our lab furnaces are fully customizable to meet your unique research needs, ensuring contamination-free results and uniform thermal distribution every time.

Ready to optimize your solid-state dewetting process? Contact KINTEK today to discuss your custom furnace solution!

Visual Guide

References

- R. Niguma, Koichi Okamoto. Novel Plasmonic Metamaterials Based on Metal Nano-Hemispheres and Metal-Dielectric Composites. DOI: 10.3390/photonics11040356

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the operating principle of a muffle furnace? Unlock Pure, Controlled Heating for Your Lab

- How does a muffle furnace convert goethite to hematite? Unlock Precision Thermal Dehydration

- What role does a muffle furnace play in TiO2 sol-gel transformation? Achieve High-Performance Photocatalytic Coatings

- What is a digital muffle furnace? A Guide to Contamination-Free, Precise Heating

- How do laboratory programmable heating furnaces verify thermal insulation and protection? Mastering Fire Simulation

- What are the primary functions of muffle furnaces? Achieve Clean, Uniform Heating for Your Materials

- What factors should users consider when selecting a box type resistance furnace? Key Insights for Optimal Performance

- What is the most common format for Controlled Atmosphere Continuous Muffle Furnaces? Belt Furnace for High-Throughput Processing