Selecting the right box resistance furnace is a critical decision that directly impacts the quality of your results and the efficiency of your operations. The most important factors to consider are your specific process requirements, including the necessary temperature range, the need for atmosphere control, and the required degree of temperature uniformity within the chamber. These technical needs must be balanced with long-term financial considerations like energy efficiency and maintenance costs.

The ideal furnace is not simply the one with the highest specifications, but the one whose performance characteristics are precisely aligned with your application. A methodical evaluation of your process needs before you assess any hardware is the key to ensuring reliable outcomes and a sound investment.

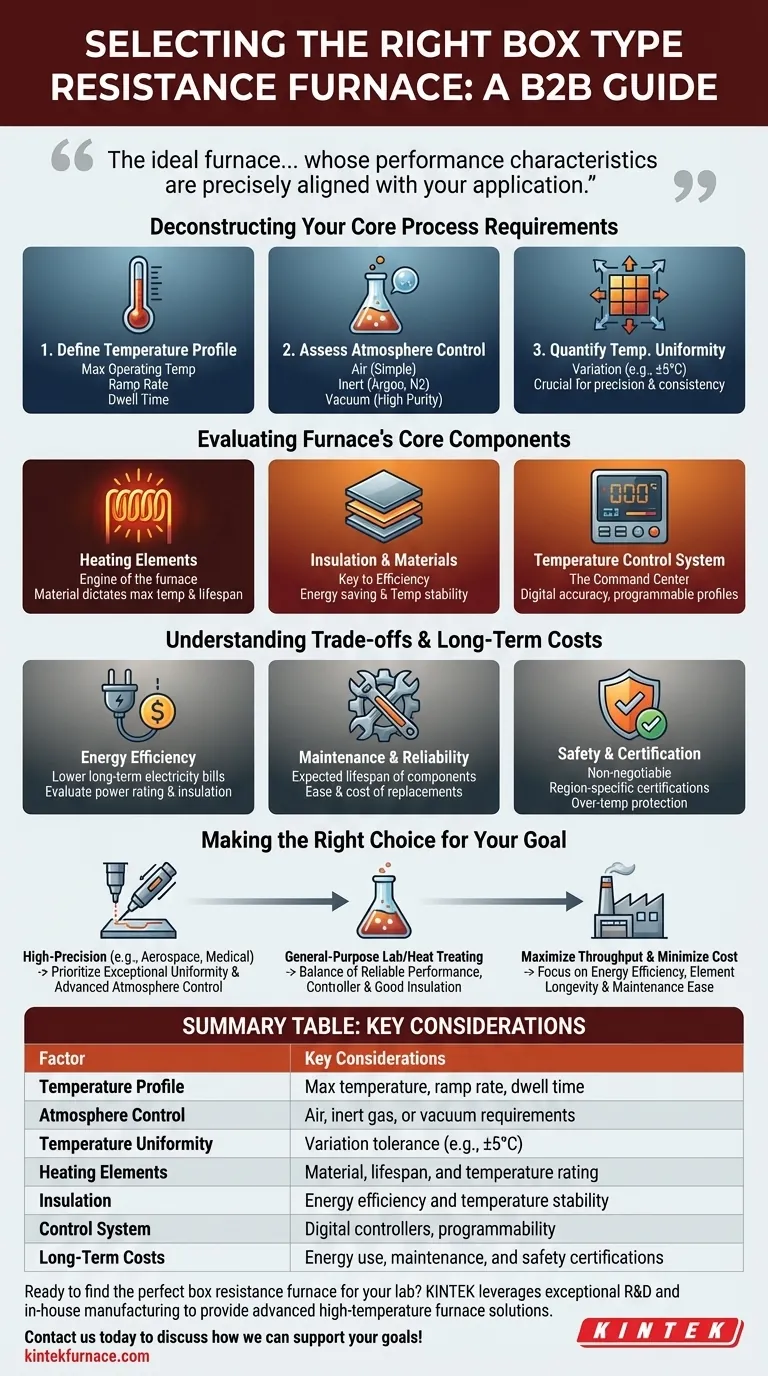

Deconstructing Your Core Process Requirements

Before evaluating any specific furnace model, you must first define the non-negotiable parameters of your thermal process. This internal clarity will serve as your guide for every subsequent decision.

Define Your Temperature Profile

The most fundamental requirement is temperature. Consider not just the maximum temperature you need to reach, but the entire thermal cycle. Ask yourself:

- What is the absolute maximum operating temperature required?

- How quickly does the furnace need to heat up (ramp rate)?

- How long will the furnace hold at a specific temperature (dwell time)?

Answering these questions ensures you select a furnace with heating elements and insulation capable of reliably executing your specific profile without being overworked.

Assess Atmosphere Control Needs

The environment inside the furnace is just as critical as the temperature. The default atmosphere in a basic furnace is ambient air.

- Air Atmosphere: Suitable for many simple heating applications, like drying or basic tempering.

- Inert Atmosphere: Processes like annealing or sintering often require an inert gas (e.g., Argon, Nitrogen) to be pumped into the chamber to prevent oxidation and ensure material purity. This requires a furnace with good sealing and gas inlet/outlet ports.

- Vacuum: For the highest level of purity and to prevent any gas-related reactions, a vacuum furnace is necessary. This represents a significant step up in complexity and cost.

Quantify Temperature Uniformity

Temperature uniformity specifies how much the temperature can vary between different points within the furnace chamber. It is often expressed as a range, such as ±5°C.

For applications involving large parts or multiple small parts in a single batch, poor uniformity can lead to inconsistent results. High-precision industries like aerospace or medical device manufacturing demand excellent uniformity to guarantee that every part is processed identically.

Evaluating the Furnace's Core Components

Once your process requirements are clear, you can begin to assess how a furnace's physical components meet those needs.

Heating Elements: The Engine of the Furnace

The heating elements are responsible for generating the heat. Their material composition dictates the furnace's maximum temperature and operational lifespan. Ensure the elements are rated for temperatures comfortably above your maximum process requirement to avoid premature failure.

Insulation and Materials: The Key to Efficiency

The quality of the furnace's insulation, often a multi-layer aluminum oxide fiber, is critical. Superior insulation provides two key benefits:

- Energy Efficiency: It prevents heat from escaping, reducing the power required to maintain temperature and lowering your operational costs.

- Temperature Stability: It helps the control system maintain a stable and uniform temperature inside the chamber.

The furnace's outer shell should be sturdy, and the internal chamber material must be able to withstand your thermal cycles without degrading.

The Temperature Control System: Your Command Center

The control system is the brain of the furnace. A modern digital controller with a high-quality temperature sensor (thermocouple) is essential for accuracy and repeatability. Advanced systems allow for programmable multi-step heating profiles, which is crucial for complex processes.

Understanding the Trade-offs and Long-Term Costs

The initial purchase price is only one part of the total cost of ownership. A truly informed decision accounts for ongoing expenses and potential risks.

Beyond Purchase Price: Energy Efficiency

A cheaper furnace with poor insulation will cost you more in the long run through higher electricity bills. Evaluating the power rating and insulation quality is essential for understanding the true operational cost.

Maintenance and Reliability

A furnace with a simple, well-designed structure can be easier and cheaper to maintain. Inquire about the expected lifespan of critical components like heating elements and the cost and availability of replacements.

Safety and Certification: A Non-Negotiable Factor

High-temperature equipment carries inherent risks. Ensure any furnace you consider has the necessary safety certifications for your region. Features like over-temperature protection and automatic shutdown are not luxuries; they are essential for protecting your personnel and facility. Always plan to follow manufacturer instructions for operation and maintenance rigorously.

Making the Right Choice for Your Goal

Your final decision should be a deliberate match between your goals and the furnace's capabilities.

- If your primary focus is high-precision material processing (e.g., aerospace, medical): Prioritize exceptional temperature uniformity (e.g., ±3°C or better) and advanced atmosphere control options.

- If your primary focus is general-purpose lab work or heat treating: A robust furnace with a reliable temperature controller and good insulation offers the best balance of performance and cost.

- If your primary focus is maximizing throughput and minimizing operational costs: Pay close attention to energy efficiency ratings, heating element longevity, and the ease and cost of maintenance.

By systematically matching your process needs to these core furnace characteristics, you can confidently select an instrument that serves as a reliable cornerstone of your work for years to come.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Profile | Max temperature, ramp rate, dwell time |

| Atmosphere Control | Air, inert gas, or vacuum requirements |

| Temperature Uniformity | Variation tolerance (e.g., ±5°C) |

| Heating Elements | Material, lifespan, and temperature rating |

| Insulation | Energy efficiency and temperature stability |

| Control System | Digital controllers, programmability |

| Long-Term Costs | Energy use, maintenance, and safety certifications |

Ready to find the perfect box resistance furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental needs for enhanced efficiency and reliability. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure