In essence, a digital muffle furnace is a high-temperature laboratory oven that uses a precise digital controller to heat materials without direct contact with the heating elements. It achieves this by heating an internal chamber, or "muffle," which then radiates heat uniformly onto the sample inside. This indirect heating method is critical for processes that require even temperatures and protection from contamination.

The core function of a muffle furnace is to provide a contamination-free, uniform heating environment. The "muffle" is the physical barrier that separates the sample from the heating source, while the "digital" controller is the brain that ensures precise temperature accuracy and control.

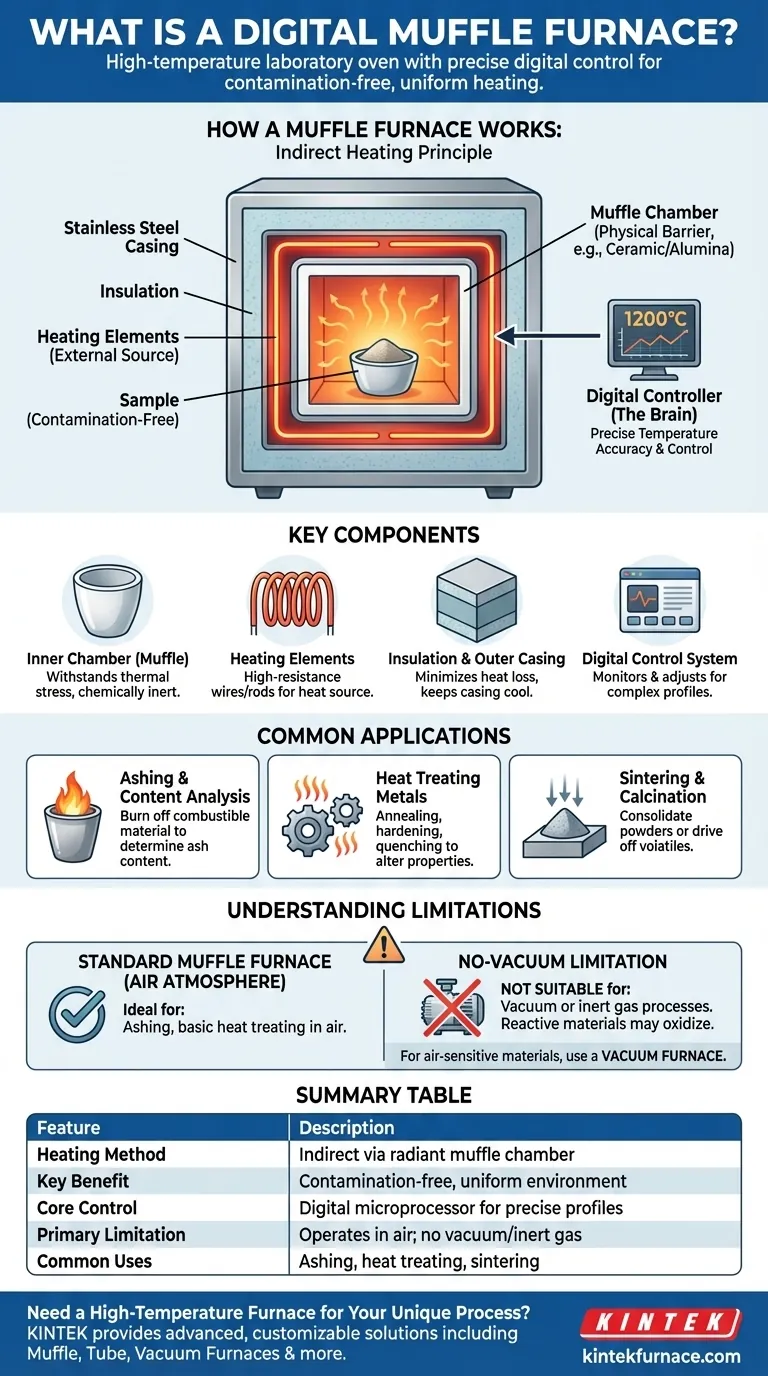

How a Muffle Furnace Works

The name "muffle furnace" directly describes its operating principle. It uses an internal chamber to muffle, or isolate, the material being heated from the raw energy source, ensuring a controlled and clean process.

The Concept of the "Muffle"

The central component is the muffle, an inner chamber typically made from high-purity refractory materials like ceramic or alumina. This chamber contains the sample but is sealed off from the actual heating elements.

The Indirect Heating Mechanism

Heating elements, often made of Kanthal or silicon carbide wire, are arranged around the outside of the muffle. These elements heat the muffle itself through radiation. The muffle then radiates that heat evenly and uniformly onto the sample inside, preventing hot spots and ensuring consistent results.

The Role of Digital Control

The "digital" aspect refers to the temperature controller. Unlike older analog models, a digital controller uses a microprocessor and sensors (like thermocouples) to precisely manage the furnace's temperature. This allows for complex heating profiles, such as ramping up to a specific temperature, holding it for a set duration, and cooling down at a controlled rate.

Key Components of a Digital Muffle Furnace

A digital muffle furnace is built from several critical components working in concert to achieve high temperatures safely and efficiently.

The Inner Chamber (Muffle)

This is the primary workspace, designed to withstand extreme thermal stress and remain chemically inert. Its material composition is vital for preventing reactions with the samples being processed.

The Heating Elements

These high-resistance wires or rods are the source of the heat. They are chosen for their ability to operate reliably at very high temperatures for extended periods.

Insulation and Outer Casing

Multiple layers of high-performance insulation, such as ceramic fiber, surround the muffle and heating elements. This minimizes heat loss, improves energy efficiency, and keeps the stainless steel outer casing cool enough to be safe.

The Digital Control System

This is the user interface and the brain of the furnace. It continuously monitors the internal temperature and adjusts power to the heating elements to follow the user-programmed temperature profile with high accuracy.

Common Applications in Science and Industry

The ability to deliver precise, uniform, and contamination-free heat makes muffle furnaces indispensable for a range of critical applications.

Ashing and Content Analysis

Furnaces are used to burn off combustible material from a sample at a controlled high temperature. This allows researchers to accurately determine the non-combustible and non-volatile content (ash) of a substance.

Heat Treating Metals

Processes like annealing (softening), hardening, and quenching rely on precise temperature control to alter the microstructure and physical properties of metals and alloys.

Sintering and Calcination

In material science, sintering is used to consolidate powdered materials into a solid mass using heat. Calcination involves heating a material to drive off volatile substances or trigger a phase transition.

Understanding the Trade-offs and Limitations

While powerful, a digital muffle furnace is not the right tool for every high-temperature application. Understanding its primary limitation is crucial for proper tool selection.

The No-Vacuum Limitation

A standard muffle furnace operates in a normal air atmosphere. It is not suitable for processes that require a vacuum or a controlled inert gas environment. Heating reactive materials in the presence of air can lead to unwanted oxidation and contamination.

When to Use a Vacuum Furnace

For applications involving air-sensitive materials or certain types of sintering where atmospheric gases would interfere with the process, a vacuum furnace is the required equipment. It is designed to pump out the air before heating, creating a pure environment.

Making the Right Choice for Your Application

Selecting the correct furnace depends entirely on the atmospheric conditions your process requires.

- If your primary focus is precise, high-temperature heating in a standard air atmosphere: A digital muffle furnace is the ideal tool for tasks like ashing, basic metal heat treating, or materials testing.

- If your primary focus is processing materials that are sensitive to air or oxygen: You must use a specialized vacuum or inert gas furnace to prevent unwanted chemical reactions.

Understanding the principle of indirect, digitally-controlled heating is the key to leveraging the power of a muffle furnace for accurate and repeatable results.

Summary Table:

| Feature | Description |

|---|---|

| Heating Method | Indirect heating via a radiant inner chamber (muffle) |

| Key Benefit | Contamination-free, uniform temperature environment |

| Core Control | Digital microprocessor for precise temperature profiles |

| Primary Limitation | Operates in air; not suitable for vacuum/inert gas processes |

| Common Uses | Ashing, heat treating metals, sintering, calcination |

Need a High-Temperature Furnace for Your Unique Process?

KINTEK's advanced digital muffle furnaces are engineered for precision and reliability. But what if your application requires more?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let us help you select or custom-build the perfect furnace for your needs.

Contact our experts today to discuss your application and receive a tailored solution.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization