The core operating principle of a muffle furnace is indirect heating within an isolated environment. It uses electrical resistance elements to heat a sealed chamber, known as the "muffle," from the outside. This design heats the sample inside without exposing it to the heating source, flames, or combustion byproducts, ensuring a process that is both highly controlled and free from contamination.

A muffle furnace's defining characteristic is not simply its ability to generate high temperatures, but its method of doing so. By separating the sample from the heat source, it prioritizes process purity and thermal uniformity above all else.

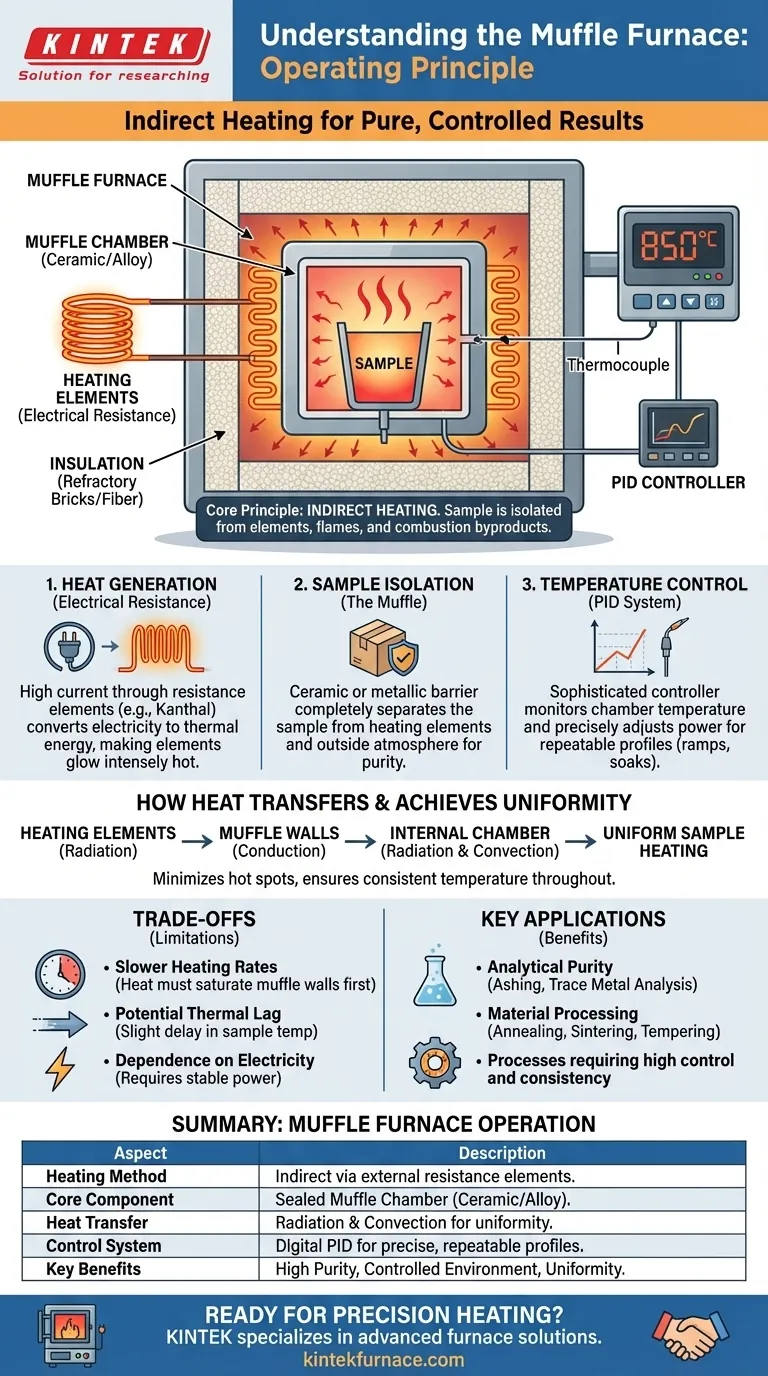

How a Muffle Furnace Achieves Indirect Heating

The furnace's operation can be broken down into three distinct functions: heat generation, sample isolation, and temperature control. Together, these elements create a stable and pristine heating environment.

The Role of Electrical Resistance

A muffle furnace generates heat by passing a high electrical current through specialized heating elements. These elements are made from materials with high electrical resistance, such as Kanthal (an iron-chromium-aluminum alloy) or nickel-chromium.

As electricity struggles to pass through these materials, the electrical energy is converted directly into thermal energy, causing the elements to glow red-hot and radiate intense heat.

The "Muffle" Chamber: The Heart of Isolation

The heating elements do not sit inside the sample chamber. Instead, they are positioned around a sealed, box-like chamber—the muffle.

This muffle is constructed from a hard, heat-resistant ceramic or metallic alloy. It serves as a physical barrier, completely isolating the sample inside from the heating elements and the outside atmosphere. This separation is the furnace's most critical feature.

Heat Transfer and Uniformity

Heat generated by the elements transfers to the sample through a two-step process. First, it radiates inward, heating the exterior walls of the muffle.

Second, that heat conducts through the muffle walls and then radiates and convects throughout the internal chamber. This indirect path ensures that heat is distributed evenly, minimizing hot spots and guaranteeing the entire sample experiences a uniform temperature.

The Function of Insulation and Control

The entire assembly is housed within a heavily insulated cabinet, often lined with refractory bricks or ceramic fiber. This insulation minimizes heat loss, improves energy efficiency, and keeps the external surfaces of the furnace safe to touch.

A sophisticated digital controller (typically a PID controller) constantly monitors the chamber temperature with a thermocouple and adjusts the power sent to the heating elements. This allows for precise, repeatable temperature profiles, including controlled ramps, soaks at a specific temperature, and cooling cycles.

Understanding the Trade-offs

While the principle of indirect heating offers significant advantages, it's important to recognize the associated limitations.

Slower Heating Rates

Because heat must first saturate the muffle's walls before reaching the sample, muffle furnaces generally have slower heating rates than direct-fired furnaces where a flame directly impinges on the material.

Potential for Thermal Lag

The indirect method can create a slight delay, or thermal lag, between the controller's setpoint and the actual sample temperature. High-quality furnaces are designed to minimize this, but it is an inherent characteristic of the design.

Dependence on Electricity

Most modern laboratory muffle furnaces are electrically powered. This provides clean and precise control but makes them dependent on a stable electrical supply, which can be a cost or logistical factor in some settings.

How to Apply This to Your Process

Understanding this operating principle helps you select and use the furnace effectively for your specific application.

- If your primary focus is analytical purity (e.g., ashing, trace metal analysis): The muffle's ability to prevent contamination from combustion gases or heating elements is its most valuable feature.

- If your primary focus is material processing (e.g., annealing, sintering, tempering): The uniform heat distribution and precise temperature control are critical for achieving consistent and repeatable material properties.

- If your primary focus is simply high-temperature heating without purity concerns: A simpler, direct-fired furnace might be a faster and more cost-effective solution for your needs.

By grasping the principle of isolated, indirect heating, you can confidently leverage the muffle furnace as a precise tool for achieving pure and predictable results.

Summary Table:

| Aspect | Description |

|---|---|

| Heating Method | Indirect heating via electrical resistance elements outside the muffle chamber |

| Core Component | Muffle chamber made of heat-resistant ceramic or alloy for sample isolation |

| Heat Transfer | Radiation and convection ensure uniform temperature distribution |

| Control System | Digital PID controller for precise temperature profiles and repeatability |

| Key Applications | Ashing, annealing, sintering, and other processes requiring purity and control |

Ready to enhance your laboratory's precision and efficiency? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements for pure, controlled heating. Don't settle for less—contact us today to discuss how our furnaces can drive your success!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites