The primary advantage of using a muffle furnace for catalyst recalcination is its ability to achieve complete structural regeneration through high-temperature thermal decomposition. While solvent washing is often limited to dissolving surface-level impurities, a muffle furnace effectively removes deep-seated organic contaminants and restores the catalyst's chemical composition to a state near its initial performance.

The Core Difference Solvent washing is a physical cleaning process, whereas use of a muffle furnace is a chemical restoration process. Thermal treatment succeeds where solvents fail by burning off organic blockers within the pores and chemically reversing deactivation caused by air exposure.

Mechanics of Contaminant Removal

Overcoming Pore Blockage

One of the most critical failures of solvent washing is its inability to penetrate the complex pore structure of a catalyst.

Contaminants often lodge deep within these internal channels, effectively reducing the active surface area.

Thermal processing in a muffle furnace circumvents this issue entirely. Heat permeates the entire catalyst particle, ensuring that contaminants deep inside the pores are addressed, not just those on the exterior.

Eliminating Persistent Organics

Catalysts often accumulate stubborn organic byproducts, specifically glycerides and fatty acid salts.

Solvents rely on solubility to remove these, which is often insufficient for compounds that have chemically adsorbed onto the surface.

High-temperature treatment utilizes thermal energy to break the chemical bonds of these contaminants, causing them to decompose or burn off completely.

Chemical Restoration of the Catalyst

Addressing Carbonate Formation

Beyond simple organic fouling, catalysts frequently degrade due to exposure to air, which leads to the formation of carbonates.

Solvent washing is generally ineffective at reversing this specific chemical change.

A muffle furnace provides the thermal environment necessary to re-oxidize these carbonates. This process converts the material back into its active oxide form, directly restoring the chemical potential of the catalyst.

Understanding the Trade-offs

The Effectiveness Gap

When choosing between these methods, you are trading operational simplicity for performance recovery.

Solvent washing may appear less intensive, but it leaves the catalyst with compromised activity because it leaves deep pores clogged and chemical degradation untreated.

Performance Longevity

A catalyst treated only with solvents will likely deactivate faster in subsequent cycles compared to one treated thermally.

Because the muffle furnace restores the material to "near initial performance," it effectively resets the catalyst's lifespan, offering a higher return on the regeneration effort.

Making the Right Choice for Your Goal

To select the appropriate method for your operation, consider the level of restoration required:

- If your primary focus is maximum activity recovery: Choose the muffle furnace. It is the only method capable of clearing internal pores and chemically re-oxidizing the catalyst surface.

- If your primary focus is removing superficial debris: Solvent washing may suffice, but you must accept that the internal structure and full catalytic efficiency will likely remain compromised.

Thermal processing is not merely cleaning; it is a true reset of the catalyst's functional capabilities.

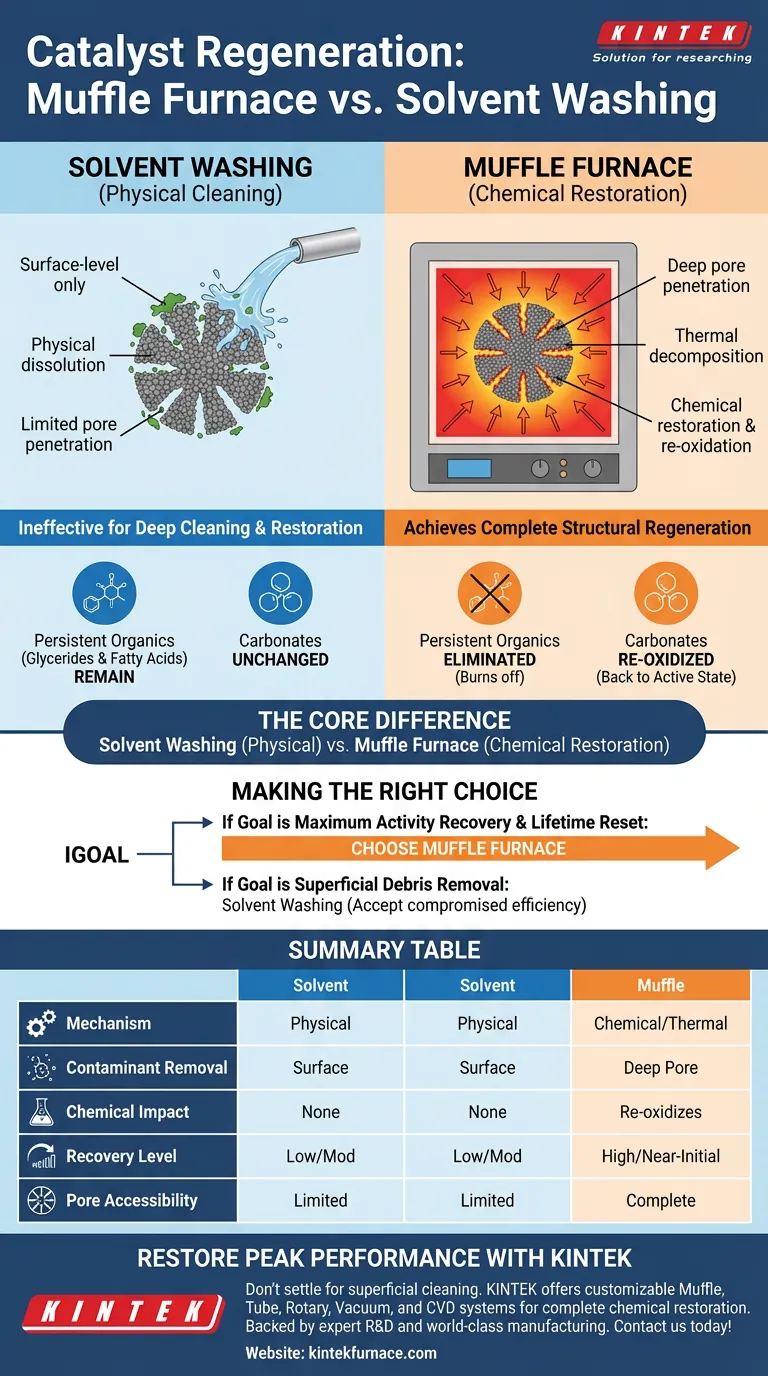

Summary Table:

| Feature | Solvent Washing | Muffle Furnace (Thermal Recalcination) |

|---|---|---|

| Mechanism | Physical dissolution | Chemical restoration & thermal decomposition |

| Contaminant Removal | Superficial/surface-level only | Deep pore penetration and total organic removal |

| Chemical Impact | None (Carbonates remain) | Re-oxidizes carbonates back to active state |

| Recovery Level | Low to moderate | High (Near-initial performance) |

| Pore Accessibility | Limited by solubility | Complete (Heat permeates entire structure) |

| Best For | Surface cleaning | Maximum activity recovery and lifetime reset |

Restore Your Catalyst's Peak Performance with KINTEK

Don't settle for superficial cleaning when you can achieve complete chemical restoration. At KINTEK, we understand that catalyst efficiency is critical to your operational success. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific temperature and atmospheric requirements.

Whether you are performing catalyst recalcination or advanced material research, our high-temperature lab furnaces provide the precision and uniformity needed to reset your materials to their initial performance levels. Contact us today to find the perfect thermal solution for your laboratory!

Visual Guide

References

- Rasa Šlinkšienė, Eglė Sendžikienė. The Regeneration of Dolomite as a Heterogeneous Catalyst for Biodiesel Production. DOI: 10.3390/catal14020139

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is the thermal sintering process in a muffle furnace necessary for post-processing aluminum matrix composites?

- What role does a laboratory oven play in lignin nanofiber stabilization? Unlock Precision Thermal Cross-linking

- How is a muffle furnace utilized in environmental analysis? Essential for Precise Organic and Inorganic Composition Testing

- What is the purpose of using a muffle furnace to fire Al2O3 ceramic shells at 1050°C? Enhance Strength and Purity

- What safety features are incorporated in muffle furnaces? Ensure Operator Protection and Equipment Safety

- What is the function of a high-temperature muffle furnace for NiO thin films? Optimize Gas Sensing Performance

- How do muffle furnaces enhance efficiency and safety? Boost Your Lab's Performance with Isolated Heating

- What role does a muffle furnace play in the SHS of lithium orthosilicate? Efficient Thermal Ignition Explained