At its core, a muffle furnace is a high-temperature oven that excels at separating a sample from the direct heat source and any contaminants. It is used across scientific and industrial fields for processes like determining the non-combustible (ash) content of a material, heat-treating components, analyzing water quality, and preparing samples for further inspection.

A muffle furnace's primary value lies in its use of indirect heating. By isolating the sample within a "muffle" or chamber, it provides a contaminant-free environment with precise, uniform high temperatures, which is critical for analytical purity and material integrity.

The Principle of Operation: Why Indirect Heating Matters

The unique capabilities of a muffle furnace stem from its fundamental design, which prioritizes a clean and controlled thermal environment. This is achieved by separating the heating elements from the internal chamber.

Isolating the Sample from Contamination

The defining feature of a muffle furnace is the muffle itself—a sealed chamber, typically made of high-temperature ceramic, that contains the sample.

Heating elements warm the outside of this chamber. Heat then transfers through the chamber walls to the sample via conduction and radiation.

This design prevents byproducts of combustion or material from the heating elements from ever touching the sample. This is essential for quantitative analysis where contamination would skew results.

Achieving Precise Thermal Control

Modern muffle furnaces use sophisticated controllers to manage and maintain specific temperature setpoints, often up to 1200°C or higher.

This precision ensures that experiments are repeatable and that materials are treated according to exact specifications, a non-negotiable requirement in both quality control and materials research.

Creating a Uniform Thermal Environment

The insulated chamber and indirect heating method work together to distribute heat evenly throughout the internal volume.

This uniformity eliminates "hot spots," ensuring that the entire sample experiences the same thermal conditions. This is vital for consistent results when ashing organic matter or annealing metal parts.

Key Scientific and Industrial Applications

The clean, controlled heat of a muffle furnace makes it an indispensable tool for a wide range of processes. Its applications are primarily centered on material transformation and analysis.

Gravimetric Analysis (Ashing)

This is one of the most common uses for a muffle furnace. A sample is heated to a high temperature to completely burn away all organic and volatile substances.

The remaining non-combustible material, known as ash, is then weighed. This process is critical for quality control in the food industry, analyzing wastewater sludge, pretreating medical samples, and determining the filler content in polymers.

Materials Science and Research

Muffle furnaces are used to develop and test the properties of high-performance materials.

This includes firing ceramics, testing the heat resistance of glass or enamel coatings, and performing heat-treatment processes like annealing and tempering on metals to alter their physical properties. It is also used for brazing, a high-temperature metal-joining process.

Forensic and Quality Control Processes

In forensic science, a furnace can be used to safely break down evidence for chemical analysis, such as in drug inspections.

In general manufacturing, it serves as a quality control tool to verify that products meet thermal stability standards or to analyze the composition of raw materials.

Understanding the Trade-offs and Limitations

While highly versatile, a muffle furnace is not the right tool for every thermal application. Understanding its limitations is key to proper use.

Not Suitable for Controlled Atmospheres

A standard muffle furnace operates in ambient air. It cannot, by itself, create a vacuum or maintain an inert gas atmosphere (like nitrogen or argon).

For processes that require a specific atmosphere to prevent oxidation, such as carburizing or sintering sensitive powdered metals, a specialized tube or retort furnace is necessary.

Risk of Thermal Shock

The rapid heating and cooling cycles can induce thermal shock, potentially cracking or destroying delicate samples like ceramics or glass.

Proper procedure requires gradual temperature ramps and allowing samples to cool slowly. Heated crucibles should always be moved to a desiccator to cool in a dry environment, preventing reabsorption of atmospheric moisture.

Operational Safety Hazards

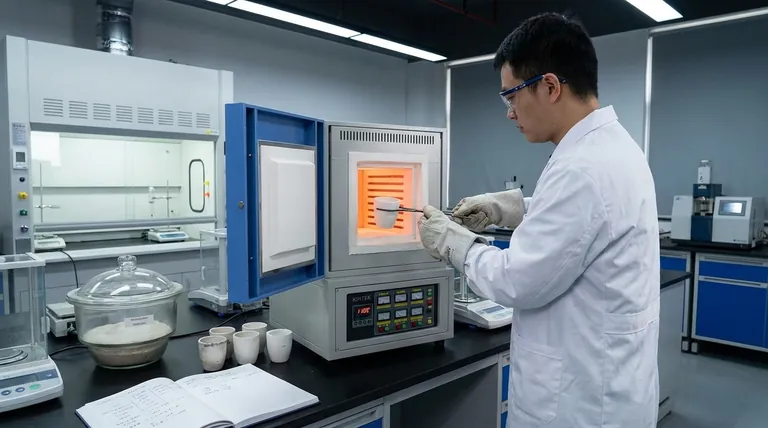

Operating a muffle furnace involves extreme temperatures and requires strict safety protocols. The outer surfaces can become very hot, and proper personal protective equipment (PPE) is essential.

Care must be taken when placing or removing samples to prevent severe burns and to ensure the stability of the items being handled.

Making the Right Choice for Your Goal

To select the correct thermal processing method, you must first define your objective.

- If your primary focus is determining inorganic content (ashing): A muffle furnace is the standard tool, providing a clean environment to burn away organic material for accurate gravimetric analysis.

- If your primary focus is heat-treating or testing materials in air: The furnace's uniform, high-temperature environment is ideal for processes like annealing, tempering, and validating the thermal resistance of coatings.

- If your primary focus requires a specific gas environment (e.g., nitrogen): You must use a specialized tube or retort furnace, as a standard muffle furnace does not control the atmosphere around the sample.

Understanding the core principle of indirect heating is the key to leveraging a muffle furnace for accurate and repeatable scientific outcomes.

Summary Table:

| Process | Key Application | Benefit |

|---|---|---|

| Gravimetric Analysis | Ashing for ash content determination | Accurate, contaminant-free results |

| Materials Science | Annealing, tempering, ceramics firing | Uniform heating for material integrity |

| Quality Control | Thermal stability testing, forensic analysis | Repeatable, controlled high temperatures |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing accuracy and efficiency. Contact us today to discuss how we can support your scientific processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?