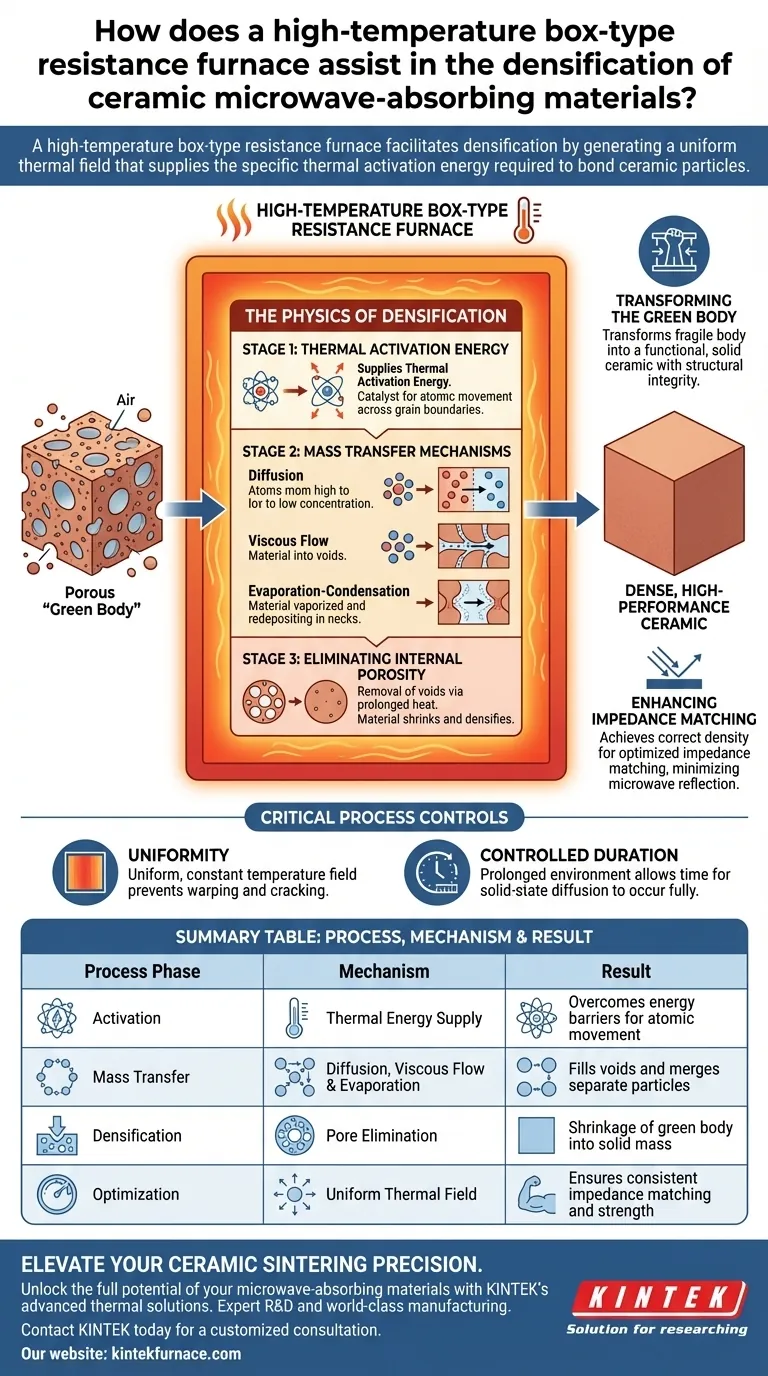

A high-temperature box-type resistance furnace facilitates densification by generating a uniform thermal field that supplies the specific thermal activation energy required to bond ceramic particles. This controlled heat triggers essential mass transfer processes—such as diffusion, viscous flow, and evaporation-condensation—which physically merge separate particles into a cohesive solid.

Core Takeaway The furnace functions as a transformation chamber, turning a porous "green body" into a high-performance ceramic. By maintaining a prolonged, high-temperature environment, it systematically eliminates internal pores, resulting in a material with the superior mechanical strength and precise impedance matching necessary for effective microwave absorption.

The Physics of Densification

Thermal Activation Energy

The primary role of the furnace is to overcome the energy barrier that keeps particles separate. It supplies thermal activation energy, which excites the atoms within the ceramic powder.

This energy is the catalyst that allows atoms to move across grain boundaries, initiating the physical changes required for solidification.

Mass Transfer Mechanisms

Once the particles are thermally activated, the furnace environment enables mass transfer. This occurs through three specific pathways:

- Diffusion: Atoms move from areas of high concentration to low concentration, filling gaps.

- Viscous Flow: The material softens slightly, allowing it to flow and fill voids.

- Evaporation-Condensation: Material vaporizes and re-deposits in narrower neck regions between particles.

Eliminating Internal Porosity

The ultimate goal of these mass transfer mechanisms is the removal of voids. The prolonged exposure to heat drives out the air pockets trapped within the printed parts.

As these internal pores are eliminated, the material shrinks and densifies, transitioning from a loosely packed structure to a solid, continuous mass.

Impact on Material Performance

Transforming the Green Body

Before sintering, the ceramic is a "green body"—a fragile, porous object held together by weak forces. The furnace drives the phase transformation that turns this green body into a functional ceramic.

This process is not merely about hardening; it is about changing the fundamental internal structure to ensure structural integrity.

Enhancing Impedance Matching

For microwave-absorbing materials, density is not just about strength; it is about electromagnetic performance. The furnace ensures the material achieves the correct density to optimize impedance matching characteristics.

Proper impedance matching minimizes the reflection of microwaves at the material surface, allowing them to enter the material and be absorbed effectively rather than bouncing off.

Critical Process Controls

The Necessity of Uniformity

A key advantage of the box-type resistance furnace is its ability to provide a uniform, constant temperature field. Inconsistent heat leads to differential shrinkage, which causes warping or cracking.

Uniformity ensures that the mass transfer processes occur evenly throughout the entire part, guaranteeing consistent properties from the surface to the core.

Controlled Duration

The reference emphasizes a prolonged high-temperature environment. Densification is not instantaneous; it requires time for solid-state diffusion to occur fully.

The furnace allows for precise control over this duration, ensuring the material has enough time to reach full density without over-firing, which could degrade the material's microstructure.

Making the Right Choice for Your Goal

If your primary focus is Mechanical Durability:

- Prioritize a sintering profile that maximizes the duration of the high-temperature hold to ensure the complete elimination of internal pores and voids.

If your primary focus is Microwave Absorption Efficiency:

- Focus on achieving the specific density that aligns with your target impedance matching; a strictly uniform temperature field is required to prevent density gradients that distort electromagnetic performance.

Precision in thermal control is the difference between a porous, reflective ceramic and a dense, highly absorbent component.

Summary Table:

| Process Phase | Mechanism | Result |

|---|---|---|

| Activation | Thermal Energy Supply | Overcomes energy barriers for atomic movement |

| Mass Transfer | Diffusion, Viscous Flow & Evaporation | Fills voids and merges separate particles |

| Densification | Pore Elimination | Shrinkage of green body into solid mass |

| Optimization | Uniform Thermal Field | Ensures consistent impedance matching and strength |

Elevate Your Ceramic Sintering Precision

Unlock the full potential of your microwave-absorbing materials with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your laboratory's exacting standards.

Whether you require precise impedance matching or superior mechanical durability, our customizable high-temperature furnaces deliver the uniform thermal field necessary for perfect densification.

Ready to optimize your material performance? Contact KINTEK today for a customized consultation.

Visual Guide

References

- Wenqing Wang, Rujie He. Advanced 3D printing accelerates electromagnetic wave absorption from ceramic materials to structures. DOI: 10.1038/s44334-024-00013-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What temperature range can muffle furnaces typically achieve? Find the Right Furnace for Your Lab Needs

- What role does a Muffle Furnace play in processing steel and soil samples for cobalt extraction? Essential Lab Guide

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- How to keep samples in muffle furnace? A Step-by-Step Guide for Safe & Accurate Results

- What role does a muffle furnace play during the calcination of Ni/Al2O3 catalysts? Optimize Your Catalyst Stability

- Why is an industrial muffle furnace required for preheating Fe-C-B-Cr-W alloys? Ensure Structural Integrity

- How are a muffle furnace and ceramic crucible used for MoO3? Master High-Purity Synthesis Today

- How are industrial-grade high-temperature muffle furnaces utilized in experimental archaeology? Unlock Ancient Tech