High-temperature preheating is critical for ensuring the successful processing of Fe-C-B-Cr-W alloys. An industrial muffle furnace is required to heat the alloy to a precise hot-working temperature of 1100 °C and maintain it, which lowers the deformation resistance of the matrix and significantly increases plasticity to facilitate smooth rotary swaging.

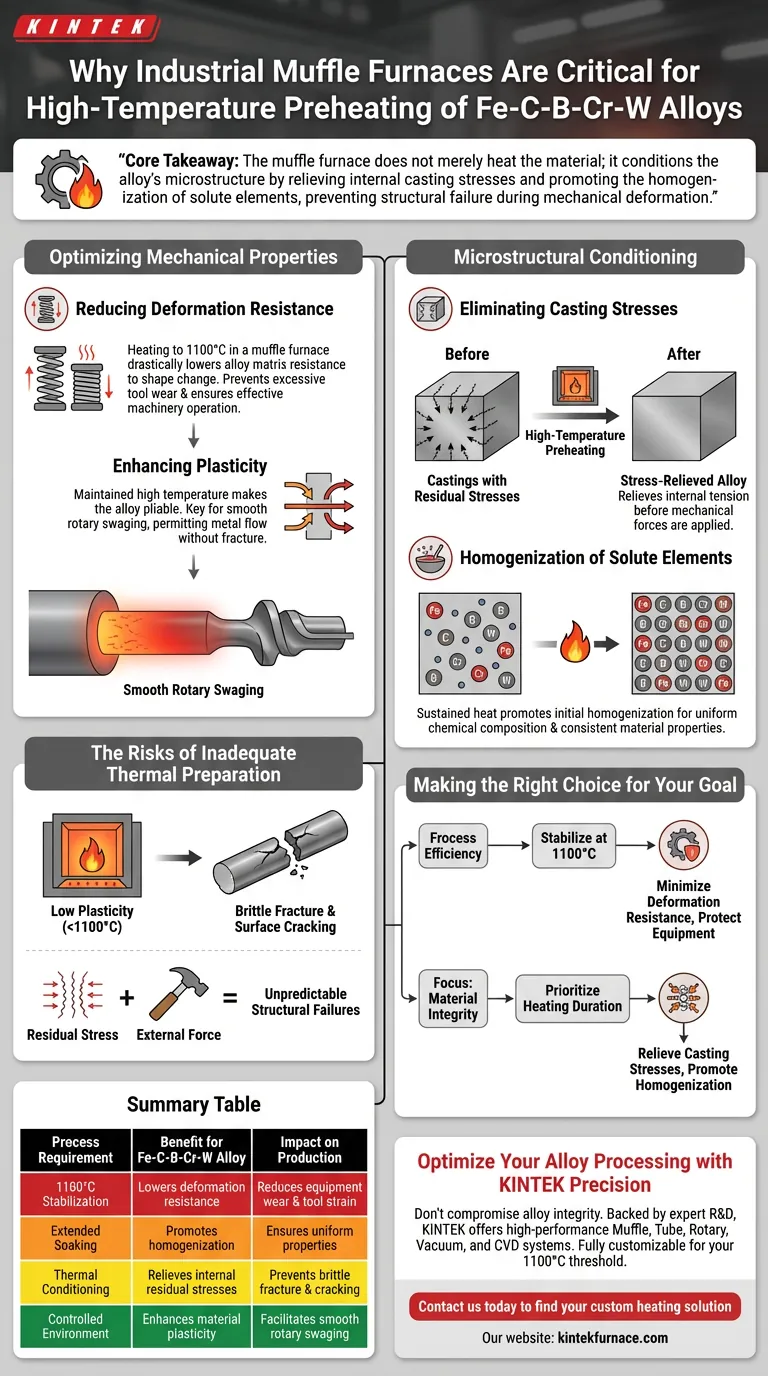

Core Takeaway The muffle furnace does not merely heat the material; it conditions the alloy’s microstructure by relieving internal casting stresses and promoting the homogenization of solute elements, preventing structural failure during mechanical deformation.

Optimizing Mechanical Properties for Deformation

To successfully work with complex alloys like Fe-C-B-Cr-W, the material must be physically prepared to withstand intense mechanical forces.

Reducing Deformation Resistance

At room temperature, the alloy matrix exhibits high resistance to shape change. Heating the material to 1100 °C in a muffle furnace drastically lowers this resistance.

This reduction is necessary to prevent excessive wear on tooling and to ensure the machinery can effectively shape the alloy without overcoming immense physical opposition.

Enhancing Plasticity

Plasticity refers to the material's ability to undergo permanent deformation without breaking.

By maintaining the high temperature within the furnace, the alloy becomes more pliable. This increased plasticity is the key factor that allows the rotary swaging process to proceed smoothly, permitting the metal to flow rather than fracture under pressure.

Microstructural Conditioning

Beyond the immediate mechanical benefits, the furnace environment addresses internal structural issues inherent in cast alloys.

Eliminating Casting Stresses

Castings often contain residual internal stresses resulting from the cooling process. If left unchecked, these stresses can lead to cracking during hot working.

High-temperature preheating effectively relieves these casting stresses, neutralizing internal tension before external mechanical forces are applied.

Homogenization of Solute Elements

In complex alloys containing Iron, Carbon, Boron, Chromium, and Tungsten, elements may be unevenly distributed after casting.

The sustained heat promotes the initial homogenization of these solute elements. This ensures a more uniform chemical composition throughout the matrix, which results in consistent material properties and behavior during the swaging process.

The Risks of Inadequate Thermal Preparation

While the benefits of preheating are clear, understanding the risks of bypassing or rushing this step is equally important.

The Consequences of Low Plasticity

If the alloy is not maintained at the target temperature of 1100 °C, the matrix retains too much rigidity.

Attempting rotary swaging on a material with insufficient plasticity typically results in brittle fracture or surface cracking, rendering the workpiece unusable.

Impact of Residual Stress

Ignoring the stress-relief aspect of preheating creates a compound loading scenario.

When the external force of swaging meets the internal force of residual casting stress, the material's failure threshold is exceeded much faster, leading to unpredictable structural failures.

Making the Right Choice for Your Goal

To achieve the best results with Fe-C-B-Cr-W alloys, apply the heating process with specific outcomes in mind.

- If your primary focus is Process Efficiency: Ensure the furnace stabilizes at 1100 °C to minimize deformation resistance, protecting your rotary swaging equipment from excessive strain.

- If your primary focus is Material Integrity: prioritize the duration of the heating phase to fully relieve casting stresses and promote element homogenization before deformation begins.

Proper thermal preparation is not just a preliminary step; it is the foundation of structural quality in hot-worked alloys.

Summary Table:

| Process Requirement | Benefit for Fe-C-B-Cr-W Alloy | Impact on Production |

|---|---|---|

| 1100°C Stabilization | Lowers deformation resistance of the matrix | Reduces equipment wear and tool strain |

| Extended Soaking | Promotes homogenization of solute elements | Ensures uniform chemical & mechanical properties |

| Thermal Conditioning | Relieves internal residual casting stresses | Prevents brittle fracture and surface cracking |

| Controlled Environment | Enhances material plasticity | Facilitates smooth and successful rotary swaging |

Optimize Your Alloy Processing with KINTEK Precision

Don't compromise the integrity of your Fe-C-B-Cr-W alloys with inconsistent thermal preparation. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of industrial metallurgy.

Our lab high-temp furnaces are fully customizable to ensure your materials reach the exact 1100°C threshold needed for maximum plasticity and stress relief. Contact us today to find your custom heating solution and see how our expertise can enhance your laboratory and production efficiency.

Visual Guide

References

- H. SCHAEFER, Sebastian Weber. Microstructure Formation in Hypoeutectic Alloys in the Fe–C–B–Cr–W System. DOI: 10.1007/s11661-024-07675-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does the airflow and temperature distribution differ between drying ovens and muffle furnaces? Key Insights for Lab Efficiency

- What role does a box laboratory furnace play in tungsten-doped germanium telluride? Master Melting & Annealing

- Why is a high-temperature muffle furnace required for U3O8 preparation? Achieving Phase Purity and Stability

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What electrical precautions should be taken when setting up a muffle furnace? Essential Safety Tips for Your Lab

- What was the initial purpose of a muffle furnace and how has it evolved? Discover Its Journey from Contamination Shield to Precision Tool

- What is a muffle furnace and how does it relate to laboratory furnaces? Discover Its Key Benefits for Your Lab

- What role does a muffle furnace play in the thermal processing of crystal synthesis? Master Precise Crystal Growth