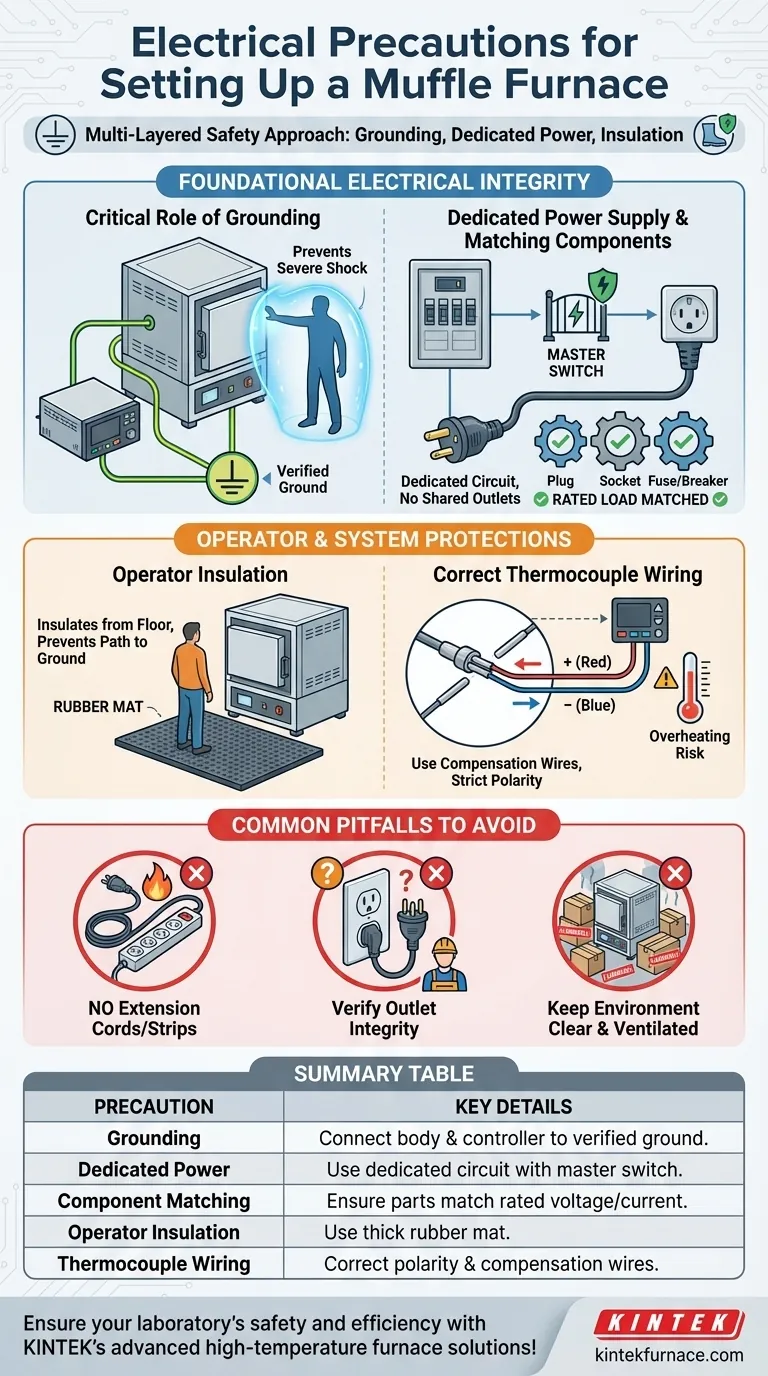

To properly set up a muffle furnace, you must implement several critical electrical precautions. The furnace requires a dedicated power circuit with a master switch, and all components—plugs, sockets, and fuses—must match the furnace's rated voltage and current. Crucially, both the furnace body and its controller must be connected to a verified ground wire to prevent the risk of severe electric shock.

Muffle furnaces are high-power industrial devices, not standard appliances. Their electrical setup requires a multi-layered safety approach where proper grounding, a dedicated power supply, and operator insulation are not optional recommendations, but fundamental requirements for safe operation.

Foundational Electrical Integrity: The Non-Negotiables

The initial electrical installation is the most critical phase for ensuring long-term safety. Mistakes here create latent hazards that can persist for years.

The Critical Role of Grounding

A proper ground connection is your primary defense against electric shock. In the event of an internal wiring fault, the ground wire provides a safe path for electricity to flow, tripping a breaker or blowing a fuse.

Without it, the metal shell of the furnace could become energized, and anyone touching it would complete the circuit to the ground, resulting in severe injury or death. Both the main furnace body and the separate controller unit must be reliably grounded.

A Dedicated and Accessible Power Supply

A muffle furnace draws a significant amount of current. It must be connected to a dedicated circuit to prevent overloading and creating a fire hazard.

Do not plug it into a circuit shared with other equipment. An additional master power switch or "electric gate" must be installed at the power line inlet. This ensures you can cut all power to the unit immediately in an emergency without having to search for a breaker panel.

Matching Components to Rated Load

The furnace's power cord, plug, wall socket, and circuit fuse or breaker are all links in a chain. Each component must be rated to handle the furnace's specified voltage and amperage.

Using undersized wires or general-purpose extension cords can cause them to overheat, melt, and ignite. Always use parts that match or exceed the manufacturer's power requirements.

Operator and System-Level Protections

Beyond the core wiring, additional layers of protection are necessary for the operator and the control system.

Operator Insulation

Even with proper grounding, an additional safety measure is to insulate the operator from the floor. Place a thick rubber mat on the ground in front of the furnace.

This mat acts as an electrical insulator, preventing the operator's body from becoming a path to ground in the unlikely event of a simultaneous equipment fault and grounding failure.

Correct Thermocouple Wiring

The thermocouple is the furnace's nerve center, providing temperature feedback to the controller. It must be connected using the correct compensation wires, with strict attention to positive and negative polarity.

Incorrect wiring can cause false temperature readings, leading the controller to overheat the furnace far beyond its setpoint. This can destroy the heating elements, damage the furnace, and create a fire hazard.

Understanding the Common Pitfalls

Many accidents result from a misunderstanding of the risks involved. Avoiding these common mistakes is as important as following the correct procedures.

Pitfall: Using an Extension Cord or Multi-outlet Strip

Never use a standard office or household extension cord to connect a muffle furnace. These are not rated for the high, sustained current draw and present a significant fire risk. The furnace must be plugged directly into a properly rated, dedicated wall socket.

Pitfall: Assuming a Three-Prong Plug is Sufficient

While a three-prong plug is necessary for grounding, you must also verify that the building's outlet is actually and properly grounded. In older buildings or those with faulty wiring, a three-prong outlet may not have a functional ground connection. Always have a qualified electrician verify the outlet's integrity.

Pitfall: Neglecting the Surrounding Environment

Electrical safety is part of a larger system. Never place flammable or explosive materials near the furnace. Ensure the workspace is clean, dry, and has adequate ventilation to handle any fumes that may be produced.

Making the Right Choice for Your Setup

Your specific precautions should align with your primary operational goals. Use this guide to ensure your setup is robust and safe.

- If your primary focus is operator safety: Prioritize a verified ground connection, a dedicated master power switch, and the use of a heavy-duty rubber mat in front of the furnace.

- If your primary focus is equipment protection and longevity: Ensure you use plugs, sockets, and fuses that match the furnace's rated load and double-check that the thermocouple is wired with the correct polarity.

- If your primary focus is general lab compliance and reliability: Mandate a dedicated, properly rated electrical circuit for the furnace and ensure all controls are clearly labeled and accessible.

A meticulous and informed electrical installation is the foundation for every safe and successful operation of your muffle furnace.

Summary Table:

| Precaution | Key Details |

|---|---|

| Grounding | Connect furnace body and controller to a verified ground wire to prevent electric shock. |

| Dedicated Power Supply | Use a dedicated circuit with a master switch to avoid overloading and fire risks. |

| Component Matching | Ensure plugs, sockets, and fuses match the furnace's rated voltage and current. |

| Operator Insulation | Place a thick rubber mat to insulate the operator from electrical hazards. |

| Thermocouple Wiring | Use correct compensation wires with proper polarity to prevent overheating and damage. |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, enhancing performance and compliance. Don't compromise on safety—contact us today to discuss how we can support your setup and protect your investments!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity