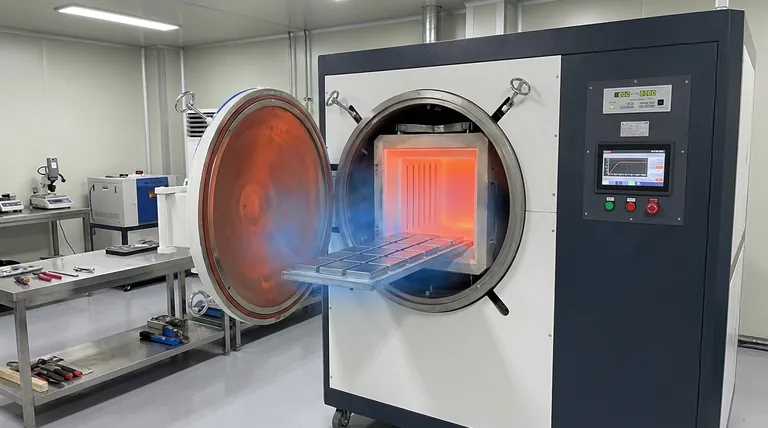

Grain Boundary Diffusion (GBD) heat treatment fundamentally alters the microstructure of high-grade magnets by infiltrating heavy rare earth elements from the surface into the material's interior. Operating at temperatures between 800°C and 900°C, these furnaces facilitate the creation of a specialized shell around the magnet's main grains, significantly enhancing magnetic properties without altering the core composition.

By targeting the distribution of dysprosium specifically to the grain boundaries rather than the entire volume, GBD furnaces increase coercivity while reducing heavy rare earth consumption by 50-60%. This process decouples performance gains from material costs, enabling the scalable production of high-performance magnets.

The Microstructural Advantage

Precise Thermal Diffusion

The core function of the GBD furnace is to manage a high-temperature environment, specifically between 800°C and 900°C.

At this temperature range, heavy rare earth elements, primarily dysprosium, become mobile. They diffuse from the magnet's surface deep into its interior structure.

Formation of the Hardening Shell

The diffusion process does not simply mix the elements; it creates a specific microstructural feature.

The dysprosium reacts to form a (Nd,Dy)₂Fe₁₄B shell that wraps around the main grains of the magnet.

This shell acts as a magnetic hardening layer, drastically improving the magnet's coercivity (its resistance to becoming demagnetized).

Economic and Efficiency Implications

Solving the Bulk Alloying Problem

Traditional methods, known as bulk alloying, require mixing dysprosium throughout the entire volume of the magnet to achieve high performance.

This is inefficient because the heavy rare earth elements are only strictly necessary at the grain boundaries to stop magnetic reversal.

Drastic Reduction in Material Costs

GBD furnaces eliminate this waste by placing the dysprosium exactly where it is needed.

The reference data indicates that this targeted approach reduces dysprosium consumption by 50% to 60% compared to traditional methods.

This makes the GBD furnace essential for the cost-effective production of high-grade magnets, as it minimizes the use of expensive raw materials.

Understanding the Trade-offs

Process Sensitivity

While GBD offers material savings, it introduces a complex thermal processing step that demands rigorous control.

The temperature window (800°C–900°C) must be maintained precisely to ensure uniform diffusion without degrading the magnet's existing properties.

Dependency on Surface Area

Because the process relies on diffusion from the exterior, the geometry of the magnet matters.

The efficiency of the (Nd,Dy)₂Fe₁₄B shell formation depends on the ability of the furnace to ensure the dysprosium penetrates effectively from the surface to the required depth.

Making the Right Choice for Your Goal

To maximize the value of a Grain Boundary Diffusion furnace, align its capabilities with your production targets:

- If your primary focus is Cost Reduction: Leverage GBD to replace bulk alloying, cutting your heavy rare earth consumption by up to 60% while maintaining target specifications.

- If your primary focus is High Performance: Utilize the furnace to maximize coercivity by ensuring the consistent formation of the (Nd,Dy)₂Fe₁₄B shell around every grain.

Implementing GBD technology is the decisive step in moving from standard manufacturing to the high-efficiency production of superior magnetic components.

Summary Table:

| Feature | Traditional Bulk Alloying | Grain Boundary Diffusion (GBD) |

|---|---|---|

| HREE Consumption | High (distributed throughout) | Low (50-60% reduction) |

| Microstructure | Homogeneous alloy | Specialized (Nd,Dy)₂Fe₁₄B shell |

| Operating Temp | Various | Precise 800°C - 900°C |

| Key Benefit | Simple process | High coercivity at lower cost |

| Efficiency | Material-intensive | Targeted element distribution |

Maximize Magnet Performance with KINTEK Precision

Ready to revolutionize your production efficiency? KINTEK’s advanced heat treatment solutions are engineered to help you achieve superior magnetic coercivity while drastically cutting material costs.

Backed by expert R&D and world-class manufacturing, we provide high-performance Vacuum, CVD, and specialized high-temperature furnace systems—all fully customizable to meet your specific GBD processing requirements. Whether you are aiming for peak performance or cost optimization, our systems ensure the precise thermal control necessary for (Nd,Dy)₂Fe₁₄B shell formation.

Take the next step in high-grade magnet manufacturing. Contact KINTEK today to discuss your custom furnace needs!

References

- Finks, Christopher. Technical Analysis: Magnet-to-Magnet Rare Earth Recycling Without Solvent Extraction (M2M-Δ Architecture) - Defense Supply Chain Resilience. DOI: 10.5281/zenodo.17625287

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What is the necessity of using a vacuum chamber before curing epoxy? Eliminate Defects for Superior Material Integrity

- How does electrode design influence the thermal field stability? Optimize Heat Uniformity in Vacuum Sintering

- What are the applications of vacuum brazing furnaces? Achieve Strong, Clean Joints for Aerospace and More

- How do vacuum furnaces contribute to the production of advanced ceramic materials? Achieve Superior Purity and Density

- Why is vacuum brazing considered a clean process? Achieve Oxide-Free, Flux-Free Metal Joining

- Why must a vacuum heat treatment furnace be used for MOF-CIGCs? Prevent Oxidation & Ensure Perfect Glass Encapsulation

- Why is a vacuum sintering furnace recommended for high-density MgO? Achieve Near-Zero Porosity & Optical Purity