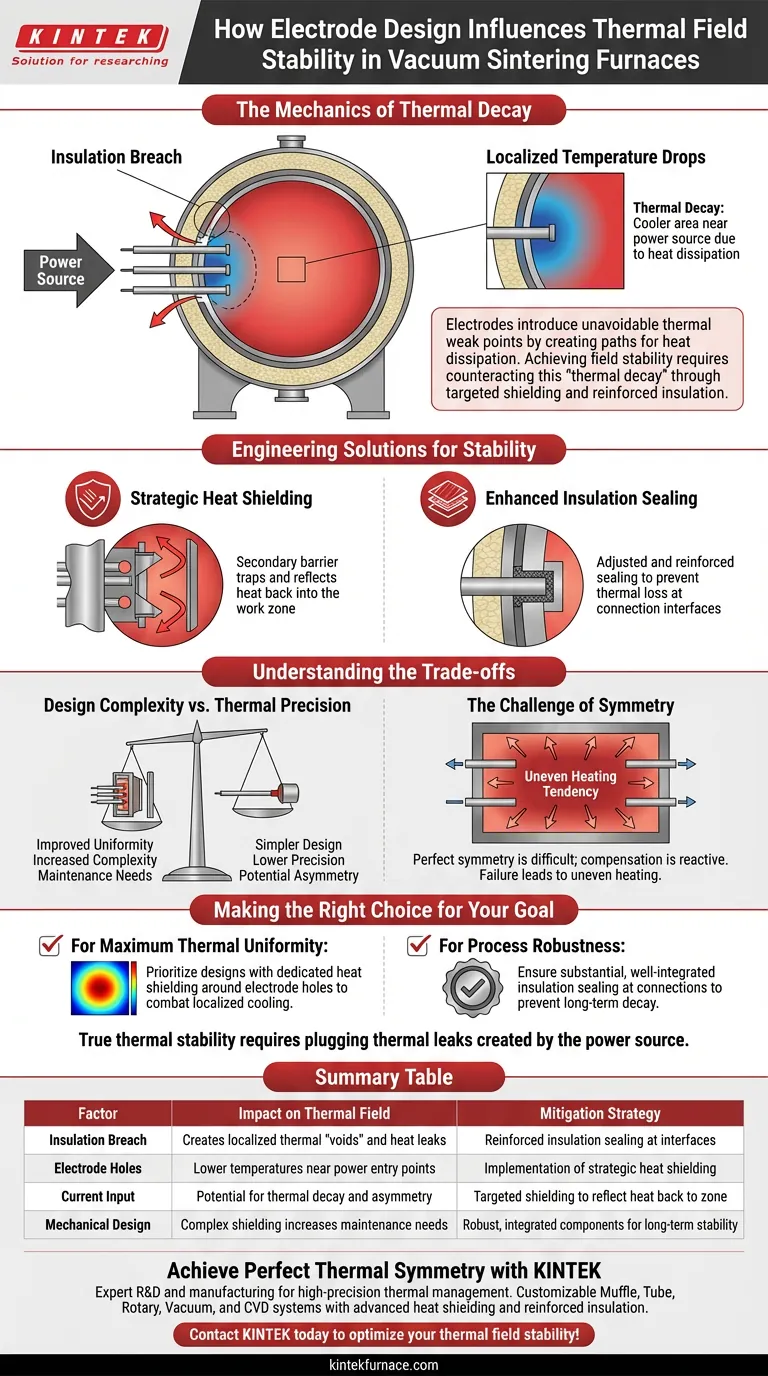

Electrode design acts as a critical variable in thermal uniformity, serving as both a power source and a potential heat sink. While electrodes are essential for introducing current, their physical structure and insertion points create localized "voids" where heat dissipates more rapidly than in the rest of the chamber. This results in lower temperatures near electrode holes, leading to thermal decay that can compromise the symmetry of the sintering process.

Electrodes introduce unavoidable thermal weak points by creating paths for heat dissipation. Achieving field stability requires counteracting this "thermal decay" through targeted shielding and reinforced insulation at connection interfaces.

The Mechanics of Thermal Decay

The Disruption of the Insulation Envelope

Electrodes serve as the interface for current input, but they physically breach the furnace's insulation layer.

This structural necessity creates a localized void. Instead of a continuous thermal barrier, the furnace has specific points where the insulation is interrupted to allow power delivery.

Localized Temperature Drops

Because of these voids, heat escapes more easily at the connection points than in the rest of the hot zone.

The temperatures near electrode holes are frequently lower than the surrounding environment. This phenomenon creates thermal decay, effectively cooling the area immediately adjacent to the power source.

Engineering Solutions for Stability

To maintain a symmetric thermal field, engineers must actively compensate for the losses caused by electrode placement.

Strategic Heat Shielding

Furnace designs often incorporate specific heat shielding structures directly around the electrode holes.

These shields act as a secondary barrier, trapping heat that would otherwise escape through the electrode void and reflecting it back into the work zone.

Enhanced Insulation Sealing

Standard insulation is often insufficient at these high-risk junction points.

To maintain overall stability, the insulation sealing at electrode connections is adjusted and reinforced. This ensures that the interface between the electrode and the furnace wall does not become a major avenue for thermal loss.

Understanding the Trade-offs

Design Complexity vs. Thermal Precision

Implementing advanced shielding around electrodes improves thermal uniformity but increases mechanical complexity.

More complex shielding structures introduce additional components inside the vacuum chamber. These components must be maintained and aligned correctly to remain effective over time.

The Challenge of Symmetry

Achieving perfect symmetry is difficult because the electrodes themselves are rarely distributed perfectly evenly across the entire surface area of the hot zone.

Compensation measures (like shielding and sealing) are reactive solutions. If these measures fail or degrade, the natural tendency of the furnace will revert to uneven heating near the power inputs.

Making the Right Choice for Your Goal

When evaluating vacuum sintering furnace designs, look closely at how the manufacturer mitigates heat loss at the power feed-throughs.

- If your primary focus is maximum thermal uniformity: Prioritize designs that explicitly feature dedicated heat shielding structures around the electrode holes to actively combat localized cooling.

- If your primary focus is process robustness: Ensure the insulation sealing at the electrode connections is substantial and well-integrated to prevent long-term thermal decay.

True thermal stability requires not just generating heat, but effectively plugging the thermal leaks created by the power source itself.

Summary Table:

| Factor | Impact on Thermal Field | Mitigation Strategy |

|---|---|---|

| Insulation Breach | Creates localized thermal "voids" and heat leaks | Reinforced insulation sealing at interfaces |

| Electrode Holes | Lower temperatures near power entry points | Implementation of strategic heat shielding |

| Current Input | Potential for thermal decay and asymmetry | Targeted shielding to reflect heat back to zone |

| Mechanical Design | Complex shielding increases maintenance needs | Robust, integrated components for long-term stability |

Achieve Perfect Thermal Symmetry with KINTEK

Thermal decay at electrode points can compromise your entire sintering process. At KINTEK, our expert R&D and manufacturing teams specialize in high-precision thermal management. We offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed with advanced heat shielding and reinforced insulation to eliminate localized cooling.

Whether you need maximum thermal uniformity or process robustness, KINTEK provides the laboratory furnace solutions tailored to your unique high-temperature needs.

Contact KINTEK today to optimize your thermal field stability!

Visual Guide

References

- Mao Li, Hesong Li. Numerical simulation of the heating process in a vacuum sintering electric furnace and structural optimization. DOI: 10.1038/s41598-024-81843-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the technical advantages of using a vacuum drying oven for electrocatalyst powders? Pt/HCCP Drying Guide

- What role does a vacuum chamber play in the Flash Joule Heating (FJH) process for LIG? Master Graphene Synthesis

- Why use low-speed heating (600-700°C) in Al-Ti-Zr sintering? Mastering Aluminum Phase Transition for Success.

- What safety benefits do vacuum furnaces offer? Inherently Safer High-Temperature Processing

- How does the digital display intelligent temperature control system work in vacuum sintering furnaces? Achieve Precise Thermal Management

- What role does a vacuum heat treatment furnace play in the preparation of SKD6 side dies? Enhance Tool Steel Longevity

- Why is long-duration temperature stability in a sintering furnace essential for Bi-2223? Master Phase Purity

- What are the steps in the discharge plasma sintering process? Master Fast, High-Density Material Consolidation