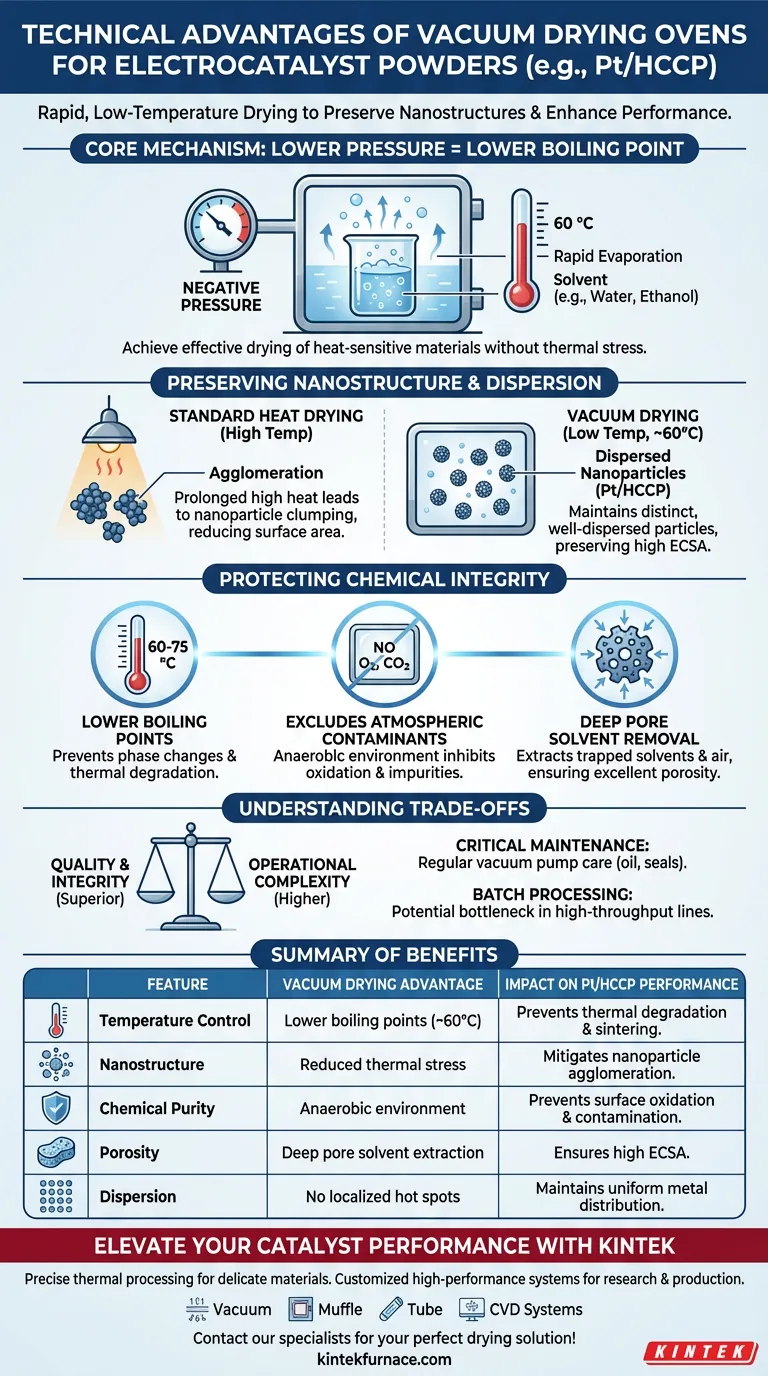

The primary technical advantage of using a vacuum drying oven for electrocatalyst powders is the ability to achieve rapid solvent evaporation at significantly reduced temperatures. By utilizing negative pressure, this method allows you to process heat-sensitive materials like Pt/HCCP at approximately 60 °C, ensuring effective drying without the thermal stress that compromises catalyst performance.

Core Takeaway Vacuum drying is not just about moisture removal; it is a preservation technique for nanostructures. By lowering the boiling point of solvents, this method prevents the agglomeration of active nanoparticles and shields the material from oxidation, directly preserving the high electrochemical active surface area required for peak catalytic efficiency.

Preserving Nanostructure and Dispersion

Mitigating Nanoparticle Agglomeration

For composite catalysts such as Pt/HCCP, the physical arrangement of platinum nanoparticles is critical. Standard heat drying often leads to the clumping (agglomeration) of these particles due to prolonged exposure to high heat.

Vacuum drying prevents this by operating at lower temperatures. This ensures the nanoparticles remain distinct and well-dispersed, maintaining the material's specific surface area.

Preventing Active Component Migration

High temperatures can cause active metal components to migrate across the support structure, leading to uneven distribution. Localized overheating is a common culprit in standard ovens.

The vacuum environment eliminates these hot spots. It ensures that the catalyst solids dehydrate rapidly and uniformly, locking the metal dispersion in place for subsequent processing steps.

Protecting Chemical Integrity

Lowering Solvent Boiling Points

The fundamental mechanism at play is the relationship between pressure and boiling points. Under negative pressure, solvents like water and ethanol boil at temperatures far below their standard thresholds (e.g., evaporating effectively at 60–75 °C).

This allows for the complete removal of moisture without subjecting the powder to temperatures that could trigger phase changes or thermal degradation.

Excluding Atmospheric Contaminants

Processing in a vacuum inherently excludes atmospheric interference. In a standard oven, air exposure can introduce moisture or impurities that react with the catalyst surface.

Vacuum drying creates a sealed environment that prevents oxidation and inhibits the formation of unwanted byproducts, such as carbonates. This is vital for maintaining the chemical purity of the active sites.

Deep Pore Solvent Removal

Catalyst powders often consist of complex agglomerates with deep internal porosity. Surface drying is insufficient for these materials.

The negative pressure effectively extracts trace solvents and air bubbles trapped deep within the powder clusters. This ensures the material retains excellent porosity, which is crucial for subsequent molding or grinding stages.

Understanding the Trade-offs

While vacuum drying is superior for quality, it introduces operational complexities compared to standard convection drying.

Equipment Maintenance is Critical: Vacuum pumps require regular maintenance (oil changes, seal checks) to maintain the necessary negative pressure. A compromise in the vacuum seal renders the low-temperature benefits void.

Batch Processing Limitations: Vacuum ovens are typically batch-process devices. Unlike continuous belt dryers, they may represent a bottleneck in high-throughput manufacturing lines, requiring careful scheduling to balance quality with production speed.

Making the Right Choice for Your Goal

To maximize the efficacy of your electrocatalyst processing, align your drying parameters with your specific material constraints.

- If your primary focus is Maximizing Active Surface Area: Prioritize vacuum drying to prevent the sintering or agglomeration of nanoparticles like Platinum, ensuring the highest possible ECSA.

- If your primary focus is Chemical Purity: Rely on the vacuum environment to exclude oxygen and carbon dioxide, preventing surface oxidation and side reactions during the drying phase.

Vacuum drying is the definitive choice when the integrity of the nanostructure outweighs the speed of production.

Summary Table:

| Feature | Vacuum Drying Advantage | Impact on Pt/HCCP Performance |

|---|---|---|

| Temperature Control | Lower boiling points (approx. 60°C) | Prevents thermal degradation and sintering |

| Nanostructure | Reduced thermal stress | Mitigates nanoparticle agglomeration/clumping |

| Chemical Purity | Anaerobic environment | Prevents surface oxidation and contamination |

| Porosity | Deep pore solvent extraction | Ensures high electrochemical active surface area (ECSA) |

| Dispersion | No localized hot spots | Maintains uniform metal distribution on support |

Elevate Your Catalyst Performance with KINTEK

Precise thermal processing is the difference between a high-efficiency catalyst and a failed batch. At KINTEK, we specialize in advanced lab solutions designed for the most delicate materials. Backed by expert R&D and manufacturing, we offer high-performance Vacuum, Muffle, Tube, and CVD systems—all fully customizable to meet the specific requirements of your electrocatalyst research and production.

Don't compromise your nanostructures. Ensure maximum active surface area and chemical purity for your Pt/HCCP powders with KINTEK’s industry-leading technology.

Contact our specialists today to find your perfect drying solution!

Visual Guide

References

- Phosphorus‐Doped Highly Crystalline Carbon for High Platinum Stability and Robust Support in Proton‐Exchange Membrane Fuel Cells. DOI: 10.1002/smtd.202500481

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why is a vacuum preheating furnace used for aluminum foam sandwich panels? Ensure High-Strength Metallic Bonding

- How does an ultra-high temperature graphitization furnace enhance thermal conductivity? | KINTEK Advanced Solutions

- Why is dual monitoring used for Tantalum annealing? Achieve 20K Precision in Vacuum Furnaces

- How is furnace brazing applied in the energy and power generation sectors? Enhance Component Reliability in Extreme Conditions

- What is the purpose of using screening equipment to pretreat magnesium slag before its recovery via vacuum distillation? Optimize Your Recovery Process

- What is the purpose of using an industrial vacuum resistance furnace? Enhancing Ti-33Mo-0.2C Alloy Performance

- How do controlled atmospheres and automated temperature cycles in a sintering furnace impact alloy quality?

- What role does vacuum annealing play in preventing material oxidation? Ensure Purity with Oxygen-Free Heat Treatment