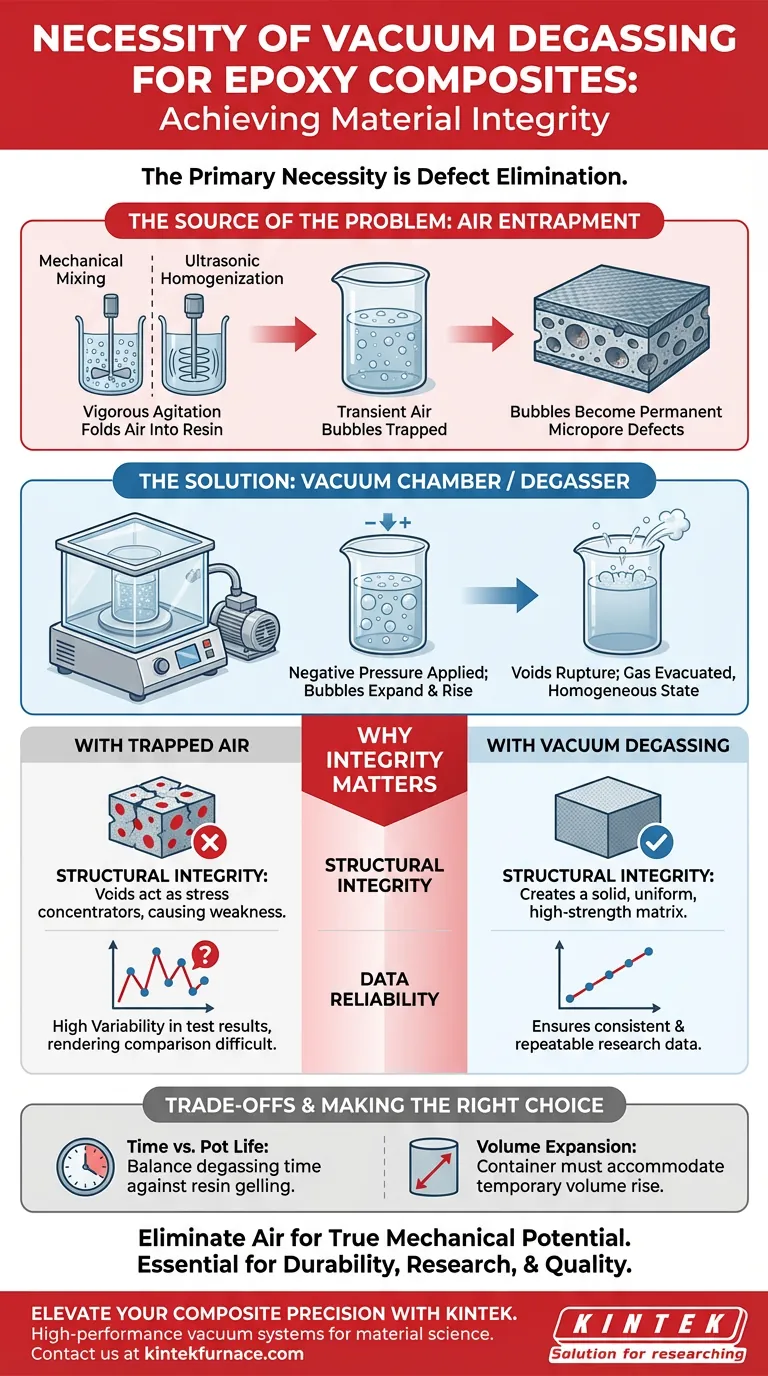

The primary necessity is defect elimination. When epoxy resin is subjected to mechanical mixing or ultrasonic homogenization, air bubbles are inevitably trapped within the viscous liquid. A vacuum chamber or degasser is required to create a negative pressure environment that forces these air pockets out of the mixture before it hardens.

The presence of trapped air creates micropore defects that fundamentally compromise the material. Vacuum degassing is essential to remove these voids, ensuring the composite maintains its intended structural integrity and yields consistent, reliable mechanical test results.

The Source of the Problem

The Inevitability of Air Entrapment

The process of preparing epoxy composites almost always involves vigorous agitation. Whether you are using mechanical mixing blades or ultrasonic homogenization to blend components, the physical action folds air into the liquid.

From Bubbles to Defects

If this mixture is allowed to cure without intervention, those transient air bubbles become permanent features of the solid material. In materials science, these are classified as micropore defects.

The Impact on the Matrix

These defects interrupt the continuity of the polymer matrix. Instead of a solid, uniform composite, you end up with a material riddled with microscopic voids that act as internal flaws.

The Mechanism of Degassing

Applying Negative Pressure

A vacuum chamber operates by significantly reducing the atmospheric pressure surrounding the resin. As the pressure drops, the trapped air bubbles expand in size and rise rapidly to the surface of the liquid.

Rupturing the Voids

Once at the surface, these bubbles rupture and the gas is evacuated from the chamber. This effectively "resets" the density of the mixture, returning it to a homogeneous state free of gas inclusions.

Why Integrity and Reliability Matter

Preserving Structural Integrity

The primary goal of a composite is usually mechanical strength or durability. Micropore defects act as stress concentrators, making the final part significantly weaker than its theoretical limit.

Ensuring Reliable Testing

For research or quality control, the reliability of data is paramount. If you test a sample full of random voids, your results will reflect the defects rather than the true properties of the material.

Consistency Across Samples

Degassing ensures that every sample is uniform. Without it, the random distribution of bubbles leads to high variability in performance data, rendering comparative analysis difficult or impossible.

Understanding the Trade-offs

Time vs. Pot Life

Vacuum degassing takes time. You must balance the duration of the vacuum process against the pot life (working time) of your epoxy; if the resin begins to gel while still under vacuum, the process will fail.

Volume Expansion

As bubbles expand under vacuum, the overall volume of the resin rises temporarily (often doubling or tripling). The container must be large enough to accommodate this rise to prevent the resin from overflowing into the vacuum pump.

Making the Right Choice for Your Goal

To ensure your composite meets your specific requirements, apply the following logic:

- If your primary focus is Structural Durability: You must degas to eliminate stress concentrators that could lead to premature cracking or failure under load.

- If your primary focus is Research and Testing: You must degas to prevent variable void content from skewing your data and reducing the repeatability of your experiments.

Eliminating air entrapment is not merely an aesthetic step; it is a fundamental requirement for achieving the true mechanical potential of epoxy composites.

Summary Table:

| Feature | Impact of Air Entrapment | Benefit of Vacuum Degassing |

|---|---|---|

| Structural Integrity | Voids act as stress concentrators; cause weakness | Creates a solid, uniform, and high-strength matrix |

| Data Reliability | High variability in mechanical test results | Ensures consistent and repeatable research data |

| Material Quality | Internal micropore defects and surface flaws | Homogeneous material free of gas inclusions |

| Performance | Premature cracking and material failure | Maximizes the theoretical mechanical potential |

Elevate Your Composite Precision with KINTEK

Don't let trapped air compromise your research or production quality. KINTEK provides high-performance vacuum chambers and degassing systems designed to meet the rigorous demands of advanced materials science. Backed by expert R&D and manufacturing, we offer customizable Vacuum, CVD, and high-temperature lab systems tailored to your unique epoxy processing needs.

Ready to eliminate defects and achieve superior material performance? Contact our specialists today to find the perfect vacuum solution for your laboratory.

Visual Guide

References

- Mertol Tüfekci, Loïc Salles. Nonlinear behaviour of epoxy and epoxy-based nanocomposites: an integrated experimental and computational analysis. DOI: 10.1080/15397734.2023.2293763

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What factors should be considered when choosing between a low vacuum and high vacuum furnace? Optimize Your Heat Treatment Process

- What is vacuum brazing and what materials does it primarily join? Discover High-Purity Joining for Superior Bonds

- Is a vacuum alone sufficient for preventing oxidation in vacuum furnaces? Master the Key Factors for Oxide-Free Results

- Why are continuous vacuum furnaces indispensable in modern metal heat treatment? Unlock Superior Quality and Efficiency

- What heating method is proposed for the vacuum chamber? Efficient Direct Resistive Heating Explained

- How does the absence of oxygen in vacuum furnaces benefit metal processing? Achieve Cleaner, Stronger Metal Parts

- What operational advantages does a vacuum heat treatment furnace offer? Achieve Superior Metallurgical Quality and Precision

- What technical advantages do vacuum high-temperature furnaces provide for sandwich panel brazing? Achieve Stronger Bonds