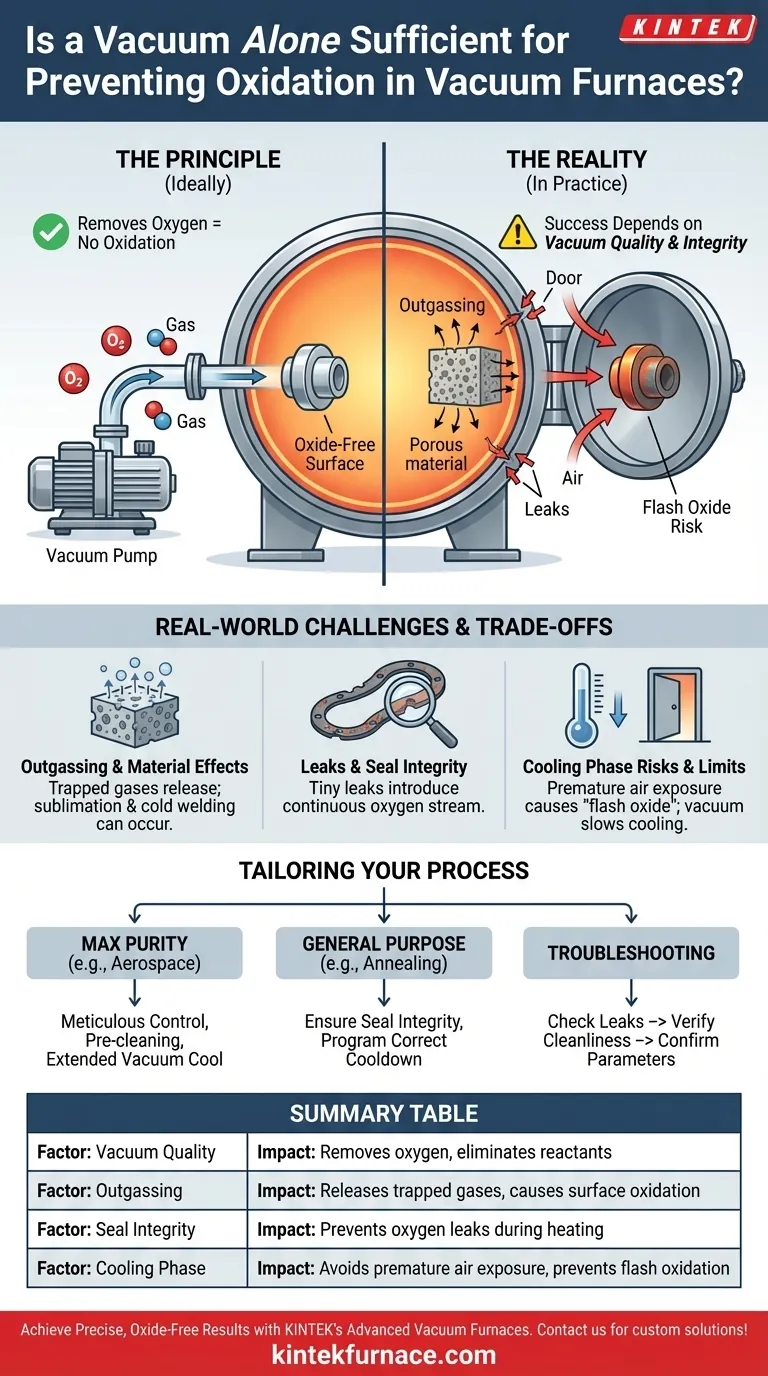

In principle, yes. A sufficiently high vacuum is the primary and most effective method for preventing oxidation in a furnace. By mechanically removing oxygen and other reactive gases from the heating chamber, you eliminate the primary reactant required for the oxidation process to occur.

The core issue is not whether a vacuum can prevent oxidation, but whether the quality and integrity of that vacuum can be maintained throughout the entire heating and cooling cycle. In practice, achieving an oxide-free result depends less on the vacuum pump alone and more on managing leaks, material outgassing, and the cooldown phase.

The Fundamental Principle: How Vacuum Prevents Oxidation

Removing the Reactant

Oxidation is a chemical reaction between a material and an oxidizing agent, most commonly oxygen. This reaction is heavily accelerated by heat.

A vacuum furnace's primary function is to pump the vast majority of air, and therefore oxygen, out of a sealed chamber before the heating process begins. Without oxygen present, oxidation simply cannot occur, regardless of the temperature.

A Clean, Controlled Environment

This process ensures that materials like metals can be heated to very high temperatures for processes like brazing, annealing, or hardening without forming undesirable oxide layers.

The result is a clean, bright surface finish and, in the case of brazing, a strong, uncontaminated joint between components.

Why a "Perfect" Vacuum Is Not the Full Story

While a vacuum is the foundation of the process, several real-world factors determine its ultimate success. The simple act of "pulling a vacuum" is not a guarantee of an oxide-free result.

The Problem of Outgassing

Many materials, especially porous ones or those with complex geometries, trap microscopic amounts of air, water vapor, and other gases.

When these materials are heated under vacuum, these trapped gases are released into the chamber in a process called outgassing. This can re-introduce enough oxygen to cause surface oxidation, even in a well-sealed furnace.

Leaks and Seal Integrity

A vacuum furnace is only as good as its seals. Gaskets, flanges, and fittings can degrade over time, creating minuscule leaks.

At high temperatures, even a very small leak can introduce a continuous stream of oxygen, compromising the entire process. This is why a "true vacuum environment," as mentioned in process guidelines, relies on meticulous system maintenance.

Contamination During Cooldown

Perhaps the most overlooked risk is premature exposure to air during the cooling cycle. A workpiece is most vulnerable to oxidation when it is hot.

If the vacuum is broken or the furnace door is opened while the material is still above its critical oxidation temperature, a "flash oxide" layer will form instantly on the surface, undoing all the work of the vacuum process.

Understanding the Trade-offs and Challenges

Relying on a vacuum for material processing introduces unique considerations that must be managed for a successful outcome.

Material-Specific Reactions

In the near-absence of gas molecules, certain materials can behave differently. Some elements may begin to sublimate, turning directly from a solid to a gas at high temperatures.

In other cases, two perfectly clean metal surfaces can fuse together under pressure without melting in a phenomenon known as cold welding. This is a direct consequence of the ultra-clean surfaces created by the vacuum.

The Limits of Cooling

A vacuum is an excellent insulator. This is a benefit for reaching high temperatures efficiently but a significant challenge for cooling.

Removing heat from the workpiece can be slow, as there is no gas to facilitate convection. This extends cycle times and requires careful management of the cooling phase to prevent thermal shock or premature exposure to air.

Equipment Maintenance and Cost

High-vacuum pumps require significant maintenance to perform reliably. Seals and gaskets are consumable components that must be regularly inspected and replaced.

Achieving and holding a high-quality vacuum is an energy-intensive process that adds to the operational cost compared to atmosphere-based heat treatment.

How to Apply This to Your Process

Your approach should be tailored to the sensitivity of your materials and the desired quality of your final product.

- If your primary focus is maximum purity and joint strength (e.g., aerospace brazing): Your success depends on meticulous process control, including pre-cleaning parts to minimize outgassing and holding the vacuum until the parts are well below their oxidation temperature.

- If your primary focus is general-purpose heat treatment (e.g., annealing): Your key concerns are ensuring the integrity of your furnace seals and confirming that your cooldown cycle is programmed correctly to prevent oxidation before the chamber is vented.

- If you are troubleshooting an oxidation problem: Investigate potential sources of contamination systematically, starting with leak detection, then verifying material cleanliness, and finally confirming your process parameters, especially the temperature at which the vacuum is broken.

Ultimately, achieving an oxide-free finish is about managing an entire system, not just relying on a single piece of equipment.

Summary Table:

| Factor | Impact on Oxidation Prevention |

|---|---|

| Vacuum Quality | Removes oxygen to eliminate oxidation reactants |

| Outgassing | Releases trapped gases that can cause surface oxidation |

| Seal Integrity | Prevents leaks that introduce oxygen during heating |

| Cooling Phase | Avoids premature air exposure to prevent flash oxidation |

Struggling with oxidation in your high-temperature processes? KINTEK specializes in advanced vacuum furnace solutions tailored for diverse laboratories. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Achieve precise, oxide-free results—contact us today to discuss how our expertise can enhance your lab's efficiency and outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today