At its core, the absence of oxygen in a vacuum furnace creates an inert environment that prevents unwanted chemical reactions during heat treatment. This allows for processing that results in metallurgically clean, uncontaminated parts, preserving or enhancing the base metal's inherent properties without the degradation caused by oxidation.

A vacuum furnace doesn't just remove air; it provides precise control over the processing atmosphere. This control is the key to preventing surface and internal contamination, enabling advanced metallurgical processes and producing components with superior strength, cleanliness, and performance.

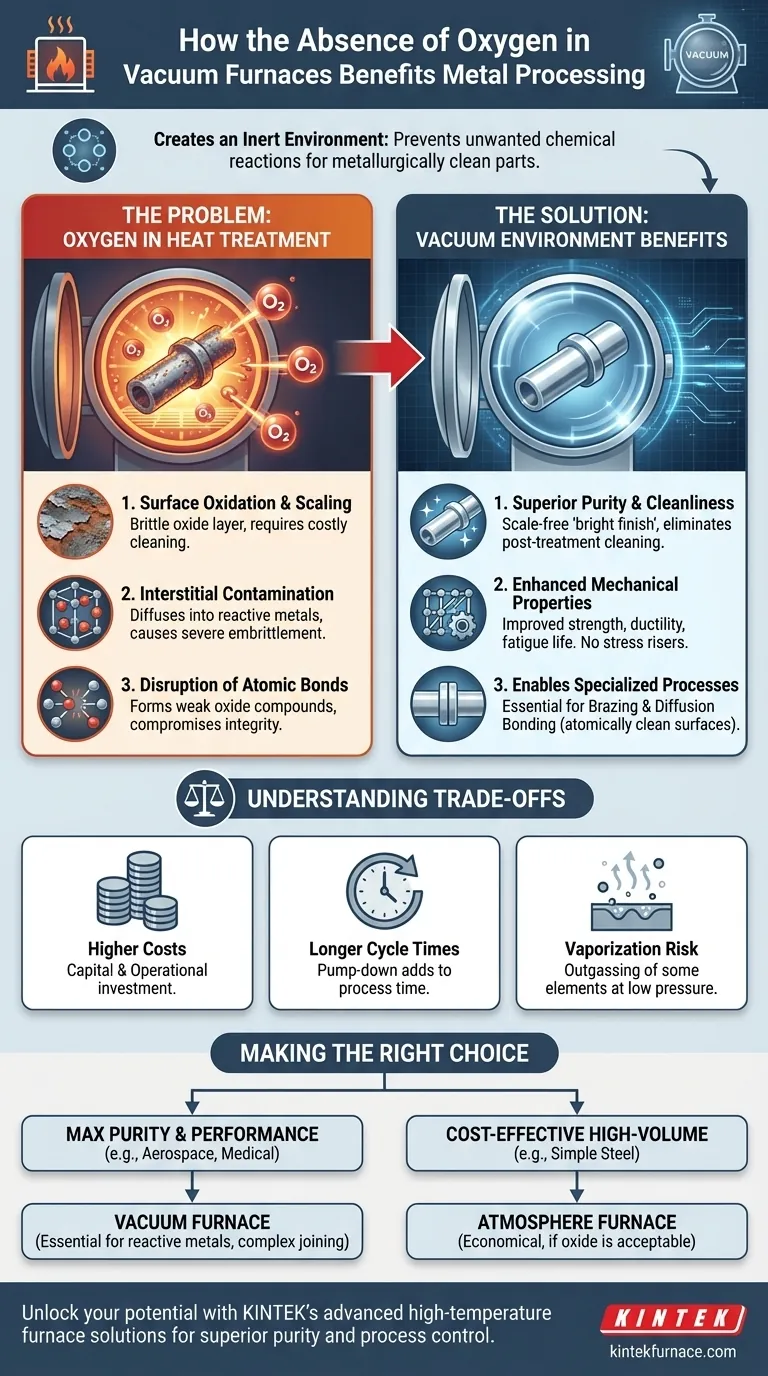

The Fundamental Problem: Oxygen in Heat Treatment

When metals are heated to high temperatures in the presence of air, oxygen is highly reactive. This reactivity is the root cause of many issues that vacuum furnaces are designed to solve.

Surface Oxidation and Scaling

At elevated temperatures, oxygen reacts with a metal's surface to form a layer of metal oxide, commonly known as scale.

This brittle, often flaky layer is undesirable. It alters the part's dimensions, creates a rough surface finish, and must be removed through costly and time-consuming secondary operations like acid pickling or abrasive blasting.

Interstitial Contamination

For certain reactive metals like titanium and zirconium, oxygen doesn't just sit on the surface. Individual oxygen atoms can diffuse into the metal's crystal lattice, lodging themselves between the metal atoms.

This interstitial contamination can significantly degrade the material's properties, most notably causing severe embrittlement and reducing ductility, even if the surface appears clean.

Disruption of Atomic Bonds

Oxidation is an electrochemical process that disrupts the strong metallic bonds that give metals their strength. When metal atoms bond with oxygen, they form weaker, non-metallic oxide compounds.

This fundamentally alters the material at the surface, creating a point of failure and compromising the integrity of the final component.

The Metallurgical Benefits of a Vacuum Environment

By removing oxygen, a vacuum furnace prevents these negative reactions and unlocks a higher level of material quality and process capability.

Achieving Superior Purity and Cleanliness

The most immediate benefit is that parts emerge from the furnace bright and clean, with no oxide scale. This is often referred to as a "scale-free" or bright finish.

This eliminates the need for post-treatment cleaning, saving time and resources while preventing the potential surface damage associated with mechanical or chemical scale removal.

Enhancing Mechanical Properties

By preventing both surface and internal oxidation, a vacuum environment preserves the metal's intrinsic chemistry and structure. This leads to superior and more predictable mechanical properties.

Components treated in a vacuum often exhibit higher fatigue life, improved strength, and greater ductility because their surfaces are free of microscopic cracks and internal contaminants that act as stress risers.

Enabling Specialized Processes

Many advanced manufacturing processes are only possible in a vacuum. Processes like high-temperature brazing and diffusion bonding rely on atomically clean surfaces to ensure a strong, continuous metallurgical bond.

Any oxide layer would act as a barrier, preventing the filler metal from wetting the surface or stopping the two parent metals from diffusing into one another.

Understanding the Trade-offs of Vacuum Furnaces

While powerful, vacuum technology is not the universal solution for all heat treatment applications. It comes with its own set of considerations.

Higher Equipment and Operational Costs

Vacuum furnaces are complex systems requiring robust chambers, sophisticated pumping systems, and precise controls. This results in a higher initial capital investment and higher operational costs compared to standard atmosphere furnaces.

Longer Process Cycle Times

Achieving a deep vacuum is not instantaneous. The time required to pump down the chamber to the target pressure level adds to the overall cycle time, which can impact throughput for high-volume production.

Risk of Element Vaporization

Under very low pressures and high temperatures, some alloying elements with high vapor pressures (like manganese, zinc, or chromium) can vaporize from the surface of the part. This phenomenon, known as outgassing, can alter the alloy's surface chemistry and must be carefully managed.

Making the Right Choice for Your Goal

Selecting the right thermal processing environment depends entirely on the material, the application, and the desired outcome.

- If your primary focus is maximum purity and performance: A vacuum furnace is essential for reactive metals (titanium, zirconium), medical implants, and critical aerospace components where contamination is not an option.

- If your primary focus is joining complex assemblies: A vacuum environment is the definitive choice for high-quality brazing and diffusion bonding, ensuring the strongest possible joints without the use of corrosive fluxes.

- If your primary focus is cost-effective, high-volume hardening: For simple carbon steels where a thin oxide layer is acceptable or easily removed, a traditional atmosphere furnace may be a more economical choice.

Ultimately, using a vacuum furnace is a decision to prioritize material integrity and process control over all other factors.

Summary Table:

| Benefit | Description |

|---|---|

| Superior Purity | Prevents oxidation and contamination, resulting in scale-free, bright finish parts without post-treatment cleaning. |

| Enhanced Mechanical Properties | Improves fatigue life, strength, and ductility by maintaining metal integrity and preventing stress risers. |

| Enables Specialized Processes | Allows for high-temperature brazing and diffusion bonding by ensuring atomically clean surfaces for strong metallurgical bonds. |

| Trade-offs | Higher costs, longer cycle times, and risk of element vaporization compared to standard furnaces. |

Unlock the full potential of your metal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering superior purity, enhanced mechanical properties, and enabling specialized processes. Don't let oxidation hold you back—contact us today to discuss how our tailored solutions can benefit your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing