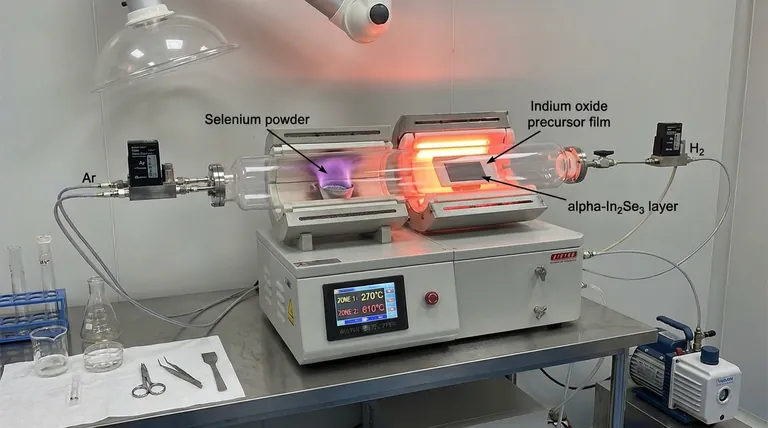

The dual-zone Chemical Vapor Deposition (CVD) furnace facilitates In-situ Growth (ISG) by mechanically decoupling the evaporation of the source material from the crystallization of the thin film. By establishing two independent thermal environments—heating the Selenium source to 270°C and the In2O3 precursor substrate to 610°C—the system creates a precise thermodynamic gradient. This control ensures the stable transport of Selenium vapor to the substrate, enabling the chemical conversion of the amorphous oxide into the desired WZ' type alpha-In2Se3 layered structure.

The core advantage of this setup is the ability to manage incompatible thermal requirements simultaneously. By isolating the vaporization of Selenium from the high-energy reaction needed at the substrate, the dual-zone furnace forces a controlled phase transition from oxide to selenide without degrading the reactants.

The Mechanics of Dual-Zone Control

Zone 1: Controlled Source Vaporization

The first zone is dedicated strictly to the Selenium (Se) source.

Because Selenium has a relatively low melting and boiling point, it requires a lower temperature setting, typically maintained at 270°C.

This prevents the rapid, uncontrolled depletion of the source material, ensuring a steady stream of vapor is released into the carrier gas.

Zone 2: High-Temperature Substrate Reaction

The second zone houses the substrate containing the In2O3 (Indium Oxide) precursor.

This zone is heated to a much higher temperature, typically 610°C, to provide the necessary activation energy for the chemical reaction.

It is within this high-heat environment that the precursor material is conditioned to accept the Selenium atoms.

Managing the Thermal Gradient

The effectiveness of the ISG process relies on the temperature gradient between these two zones.

The furnace creates a flow dynamic where Selenium vapor travels from the cooler upstream zone to the hotter downstream zone.

This transport mechanism ensures that reactants mix fully in the gas phase, which is critical for achieving high-density films.

The In-Situ Selenization Process

Driving the Chemical Reaction

The primary function of the ISG method is in-situ selenization.

As the Selenium vapor reaches the heated substrate, it reacts directly with the In2O3 precursor.

This reaction facilitates a structural transition, converting the material from an amorphous oxide into a crystalline layered selenide.

Ensuring Purity and Uniformity

The CVD process occurs in the gas phase, allowing for the complete mixing of reactants before deposition.

This prevents the introduction of contaminants that often occur in liquid-phase or physical mixing methods.

The result is a thin film with ideal quality, characterized by high density and uniform thickness.

Understanding the Trade-offs

Calibration Complexity

While dual-zone furnaces offer superior control, they introduce significant complexity in calibration.

You must precisely tune the flow rate of the carrier gas relative to the temperature of both zones; a slight misalignment can lead to Selenium condensation or incomplete selenization.

Throughput Limitations

The requirement for precise thermal gradients can limit the effective loading area of the furnace.

Unlike single-zone batch processing, the sweet spot for the In2O3 reaction is spatially limited to the region where the temperature is exactly 610°C and vapor concentration is optimal.

Optimizing Your Synthesis Strategy

To achieve the best results with WZ' type alpha-In2Se3 thin films, align your furnace settings with your specific material goals:

- If your primary focus is Phase Purity: Prioritize the stability of the 270°C source zone to ensure the Selenium supply never fluctuates during the reaction.

- If your primary focus is Film Crystallinity: Focus on optimizing the 610°C substrate zone to ensure sufficient energy is available for the oxide-to-selenide structural transition.

Mastering the thermal separation between source and substrate is the single most critical factor in reproducible high-quality ISG synthesis.

Summary Table:

| Feature | Zone 1 (Source) | Zone 2 (Substrate) |

|---|---|---|

| Material | Selenium (Se) | Indium Oxide (In2O3) |

| Temperature | 270°C | 610°C |

| Function | Controlled Vaporization | High-Energy Reaction |

| Mechanism | Steady Vapor Stream | In-situ Selenization |

| Goal | Prevent Source Depletion | Crystalline Phase Transition |

Elevate Your Thin Film Synthesis with KINTEK

Precise thermal gradients are the secret to high-purity alpha-In2Se3 growth. At KINTEK, we specialize in high-performance CVD systems, including advanced dual-zone, vacuum, and customizable tube furnaces designed to meet the rigorous demands of material science R&D.

Our expert-engineered systems provide the mechanical decoupling and thermal stability necessary for successful in-situ growth and complex chemical conversions. Whether you need a standard setup or a bespoke solution for unique material requirements, KINTEK’s R&D team is ready to support your laboratory's success.

Ready to optimize your CVD process? Contact us today to discuss your project requirements!

References

- Yuxuan Jiang, Zhidong Zhang. 2D ferroelectric narrow-bandgap semiconductor Wurtzite’ type α-In2Se3 and its silicon-compatible growth. DOI: 10.1038/s41467-025-62822-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does process complexity compare between PVD and CVD? Uncover Key Differences for Your Lab

- What are the different types of chemical vapour deposition? A Guide to Selecting the Right CVD Process

- What materials are commonly used in CVD coating systems? Explore Key Materials for Superior Coatings

- What is the significance of the vacuum pressure control system in the CVD coating process for powders?

- Why use Argon and Hydrogen for MnS Nanosheet CVD? Achieve High-Purity Synthesis Results

- How are CVD furnaces utilized in the energy sector? Powering Solar and Battery Innovations

- What drives the precursor generation and decomposition in CVD? Master Thermodynamics and Kinetics for Superior Film Growth

- What are the technical advantages of using a CVD system? Optimize Carbon Nanotube Growth for Thermal Conductivity