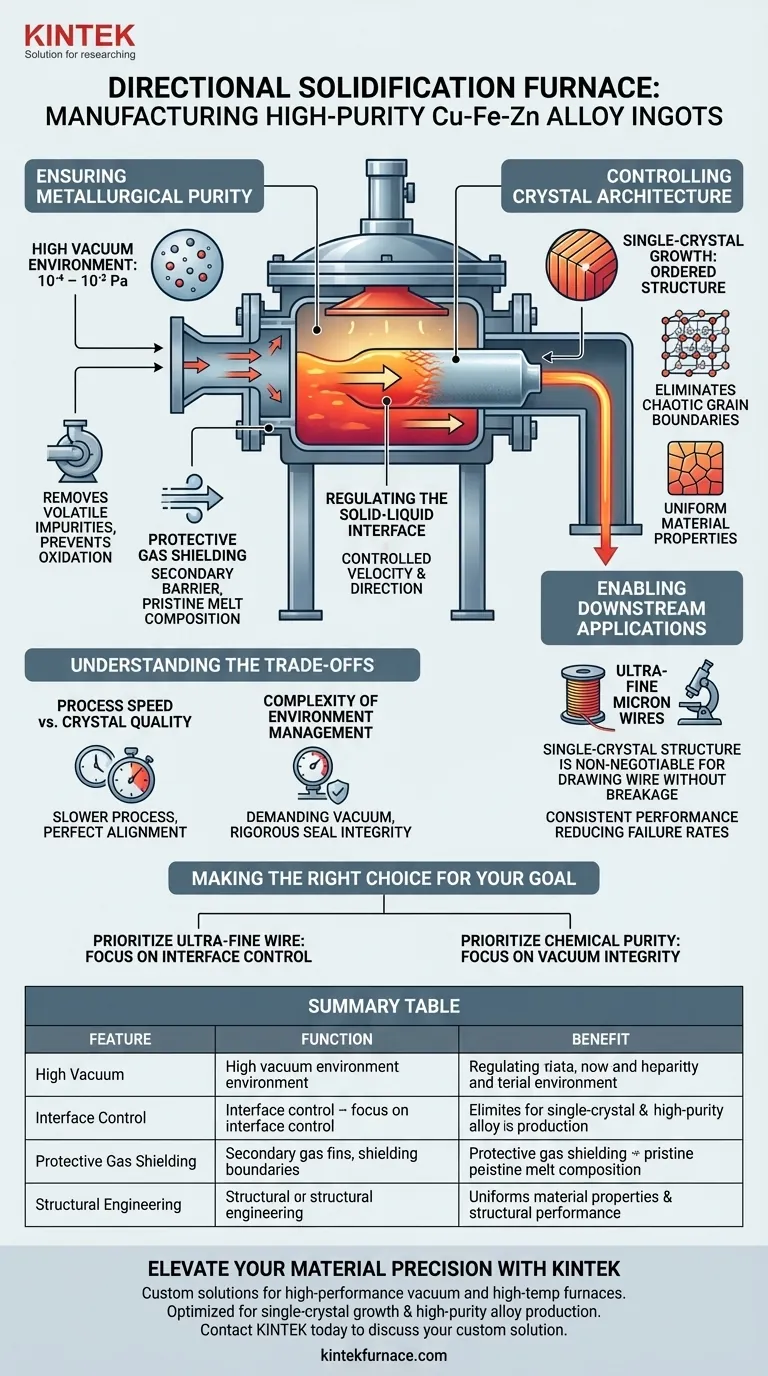

A directional solidification furnace acts as the critical control center for manufacturing high-purity Cu-Fe-Zn alloy ingots by strictly managing both the chemical purity and the physical structure of the metal. It achieves this by maintaining a high vacuum environment between 10⁻⁴ and 10⁻² Pa to eliminate contaminants, while simultaneously controlling the velocity and direction of the solid-liquid interface to force single-crystal growth.

The furnace is not merely a melting vessel; it is a structural engineering tool. Its primary value lies in transforming the alloy from a chaotic liquid into an ordered, single-crystal solid, which is a prerequisite for successfully manufacturing ultra-fine micron wires.

Ensuring Metallurgical Purity

The Critical Vacuum Environment

To achieve high purity, the furnace isolates the molten alloy from atmospheric contaminants.

It operates under a high vacuum ranging from 10⁻⁴ to 10⁻² Pa. This extreme low-pressure environment removes volatile impurities and prevents oxidation, which could otherwise compromise the alloy's conductivity and mechanical strength.

Protective Gas Shielding

Beyond the vacuum, the furnace utilizes high-purity protective gases.

This creates a secondary barrier against contamination. This "clean room" approach ensures that the chemical composition of the Cu-Fe-Zn melt remains pristine throughout the solidification process.

Controlling Crystal Architecture

Regulating the Solid-Liquid Interface

The defining feature of this furnace is its ability to manipulate the solid-liquid interface.

Unlike standard casting, where cooling happens randomly, this furnace precisely controls the direction and velocity at which the liquid metal turns to solid. This control dictates exactly how the atoms align as they freeze.

Achieving Single-Crystal Growth

By controlling the interface movement, the furnace promotes the growth of high-quality single-crystal ingots.

This ordered growth eliminates chaotic grain boundaries. A single-crystal structure creates a continuous, uniform material rather than a patchwork of microscopic crystals.

Enabling Downstream Applications

Foundation for Ultra-Fine Wires

The output of this furnace is directly linked to the feasibility of subsequent processing steps.

The text identifies this process as essential for producing ultra-fine micron wires. Without the single-crystal structure provided by directional solidification, the alloy would likely fracture or break when drawn down to micron diameters.

Consistency in Performance

The structural uniformity achieved ensures consistent high performance in the final product.

Because the ingot is grown with such precision, the electrical and mechanical properties remain uniform along the entire length of the resulting wire, reducing failure rates in high-tech applications.

Understanding the Trade-offs

Process Speed vs. Crystal Quality

Directional solidification is inherently a slower process than conventional casting.

The solid-liquid interface must move at a strictly controlled, often slow velocity to ensure perfect crystal alignment. Rushing this process to increase throughput risks introducing defects or stray grains, negating the benefits of the furnace.

Complexity of Environment Management

Maintaining a vacuum of 10⁻⁴ Pa is technically demanding.

It requires robust pumping systems and rigorous seal integrity. Any leak or failure in the vacuum system directly impacts the purity of the Cu-Fe-Zn alloy, potentially rendering the batch unsuitable for ultra-fine wire drawing.

Making the Right Choice for Your Goal

When evaluating the role of this furnace in your production line, consider your end-product requirements:

- If your primary focus is manufacturing ultra-fine micron wires: You must prioritize the control of the solid-liquid interface, as a single-crystal structure is non-negotiable for drawing wire without breakage.

- If your primary focus is chemical purity: You must prioritize the vacuum integrity (10⁻⁴ to 10⁻² Pa) to prevent oxidation and inclusions that degrade electrical performance.

The directional solidification furnace bridges the gap between raw alloy potential and the rigorous demands of precision micro-manufacturing.

Summary Table:

| Feature | Function in Cu-Fe-Zn Production | Benefit for Ingot Quality |

|---|---|---|

| High Vacuum (10⁻⁴–10⁻² Pa) | Removes volatile impurities and prevents oxidation | Ensures superior chemical purity and conductivity |

| Interface Control | Regulates solid-liquid boundary velocity and direction | Eliminates grain boundaries for single-crystal growth |

| Protective Gas Shielding | Secondary barrier against atmospheric contaminants | Maintains pristine melt composition throughout process |

| Structural Engineering | Transforms chaotic liquid into ordered solid | Enables drawing of ultra-fine micron wires without breakage |

Elevate Your Material Precision with KINTEK

Ready to achieve the metallurgical perfection required for ultra-fine micron wires? Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum systems and high-temp furnaces, including Muffle, Tube, Rotary, and CVD systems—all customizable for your unique material needs.

Our specialized equipment ensures the strict vacuum integrity and thermal control necessary for superior single-crystal growth and high-purity alloy production. Contact KINTEK today to discuss your custom solution and see how our expertise can optimize your high-tech manufacturing process.

Visual Guide

References

- Xiaohui Qiu, Jianda Zhou. Interstitial N‐Strengthened Copper‐Based Bioactive Conductive Dressings Combined with Electromagnetic Fields for Enhanced Wound Healing. DOI: 10.1002/adhm.202501303

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is an IGBT induction melting machine? Unlock Faster, More Efficient Metal Melting

- What metals and alloys can be cast using induction furnaces? Unlock Precision Melting for All Conductive Metals

- What is the function of a vacuum arc melting furnace in Cobalt-based alloy prep? Achieve High Purity & Homogeneity

- What precious metals can be melted in induction furnaces? Efficient, Clean Melting for Gold, Silver, and Platinum Group Metals

- What is the function of a vacuum induction furnace in FeAl alloy melting? Ensure Purity and Precision

- What is the role of the control circuit in an induction heater? Unlock Precision and Efficiency in Your Heating Process

- Why is repeated melting necessary for AlCoCrFeNi2.1 HEA? Achieving Chemical Uniformity in High-Entropy Alloys

- Why are induction furnaces preferred for copper melting applications? Achieve High Efficiency and Superior Quality