In short, yes. An induction furnace is not only capable of melting precious metals, but it is one of the most effective and preferred methods for the task. It can handle the full spectrum of precious metals, including gold, silver, and all platinum group metals (PGMs) like platinum, iridium, and rhodium, making it a cornerstone technology for jewelry manufacturing and metal refining.

The core challenge in working with precious metals is not simply melting them, but doing so without loss or contamination. Induction furnaces excel because they offer the precise control and clean heating environment necessary to preserve the purity and value of these high-worth materials.

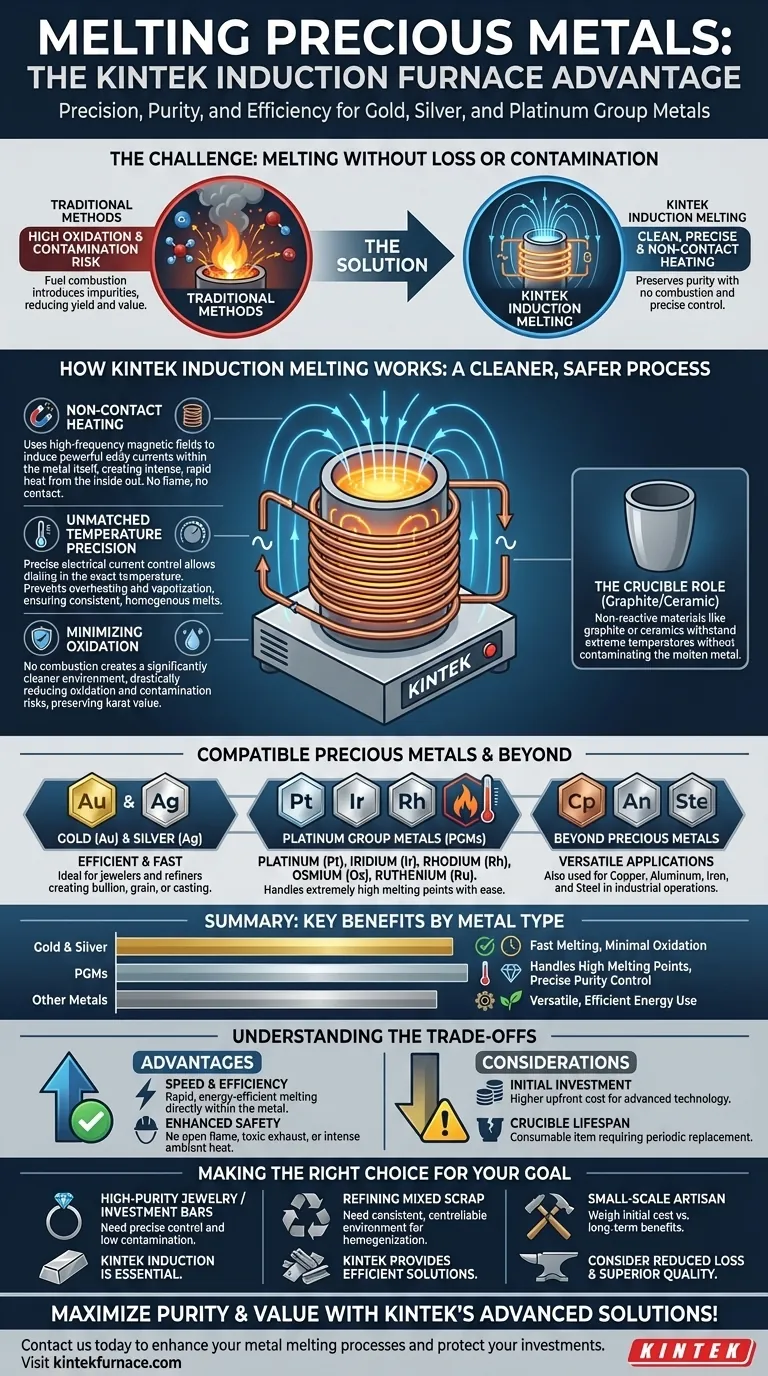

How Induction Melting Protects Precious Metal Value

The effectiveness of induction furnaces stems from their unique heating method, which is fundamentally different from traditional flame-based furnaces. This difference provides several critical advantages when handling valuable assets.

The Principle of Non-Contact Heating

An induction furnace uses a powerful, high-frequency alternating current passed through a copper coil. This creates a fluctuating magnetic field around the crucible holding the metal.

This magnetic field induces powerful electrical currents—known as eddy currents—directly within the conductive metal. The metal's natural resistance to these currents generates intense, rapid heat from the inside out. It's the metal itself that heats up, not the surrounding air.

Unmatched Temperature Precision

Because the heating is generated by an electrical current, the power level can be controlled with extreme precision. This allows you to dial in the exact melting temperature for a specific metal or alloy.

This control prevents overheating, which can cause valuable metal to vaporize and be lost. It also ensures a consistent, homogenous melt, which is critical for creating high-quality alloys.

Minimizing Oxidation and Contamination

Traditional furnaces burn fuel, introducing combustion byproducts and high levels of oxygen that can react with the molten metal. This process, called oxidation, creates impurities and reduces the final yield.

Induction heating involves no combustion, creating a much cleaner melting environment. This significantly reduces the risk of oxidation and contamination, ensuring the final product maintains its purity and karat value.

The Critical Role of the Crucible

The crucible, the container that holds the metal, is a crucial component. In an induction system, crucibles are typically made from non-reactive materials like graphite or specialized ceramics.

These materials are chosen because they can withstand extreme temperatures without reacting with or contaminating the molten precious metal, further safeguarding the material's integrity.

Compatible Metals: From Gold to Platinum

Induction technology is remarkably versatile. Its ability to generate heat is dependent only on the material's electrical conductivity, not its melting point.

Gold and Silver

Gold and silver are easily and efficiently melted in an induction furnace. The speed and cleanliness of the process make it ideal for jewelers and refiners creating bullion, grain, or casting jewelry.

The Platinum Group Metals (PGMs)

This group includes platinum, iridium, rhodium, osmium, and ruthenium. These metals are known for their extremely high melting points, which can be a challenge for conventional furnaces.

Induction furnaces can achieve these high temperatures with ease, making them one of the few practical methods for melting and alloying metals from the platinum group.

Beyond Precious Metals

The same principles apply to a wide range of other metals. Industrial operations use induction furnaces to melt everything from copper and aluminum to iron and steel, demonstrating the technology's robust and versatile nature.

Understanding the Trade-offs

While highly effective, induction technology is not without its considerations. An objective assessment requires looking at both its powerful advantages and its practical limitations.

Advantage: Speed and Efficiency

Because heat is generated directly within the metal, melting is incredibly fast and energy-efficient. There is very little wasted energy heating the furnace chamber or the surrounding environment.

Advantage: Enhanced Safety

With no open flame, toxic exhaust, or intense ambient heat, induction furnaces are significantly safer to operate than fuel-fired alternatives. This reduces fire risk and creates a more comfortable working environment.

Consideration: Initial Investment

The primary trade-off is cost. The technology involved in an induction furnace—the power supply, copper coils, and control systems—results in a higher initial purchase price compared to a simple gas furnace.

Consideration: Crucible Lifespan

While essential for purity, the crucibles are consumable items. The intense thermal cycling of repeated melts will eventually cause the crucible to degrade, requiring replacement. This is an ongoing operational cost to factor in.

Making the Right Choice for Your Goal

The decision to use an induction furnace depends on balancing its precision and purity benefits against the initial investment. Your specific application will determine if it is the right choice.

- If your primary focus is high-purity jewelry or investment-grade bars: The precise temperature control and low contamination of induction melting are essential to protect your material's value.

- If you are refining mixed precious metal scrap: Induction heating provides the consistent and controllable environment needed to efficiently manage the melt and ensure proper homogenization or separation.

- If you are a small-scale artisan with a limited budget: You must weigh the high initial cost of an induction furnace against the long-term benefits of reduced metal loss and superior quality control.

Ultimately, induction technology empowers you to melt precious metals not just effectively, but with the control and cleanliness necessary to preserve their inherent worth.

Summary Table:

| Metal Type | Examples | Key Benefits |

|---|---|---|

| Gold & Silver | Gold, Silver | Fast melting, minimal oxidation, ideal for jewelry and bullion |

| Platinum Group Metals (PGMs) | Platinum, Iridium, Rhodium | Handles high melting points, precise temperature control for purity |

| Other Metals | Copper, Aluminum, Steel | Versatile applications, efficient energy use in industrial settings |

Maximize the purity and value of your precious metals with KINTEK's advanced induction furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs precisely. Contact us today to learn how our technology can enhance your metal melting processes and protect your investments!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification