In an induction heater, the control circuit acts as the system's intelligent brain. It is the decision-making center that regulates the entire heating process by managing power output, operating frequency, and workpiece temperature. Using components like microcontrollers and feedback sensors, it makes constant, real-time adjustments to the driver circuit to ensure the heater performs precisely as required for a specific task.

An induction heater's raw power is ineffective without precision. The control circuit's fundamental role is to transform that power into a repeatable, efficient, and safe industrial process by constantly monitoring conditions and adjusting performance.

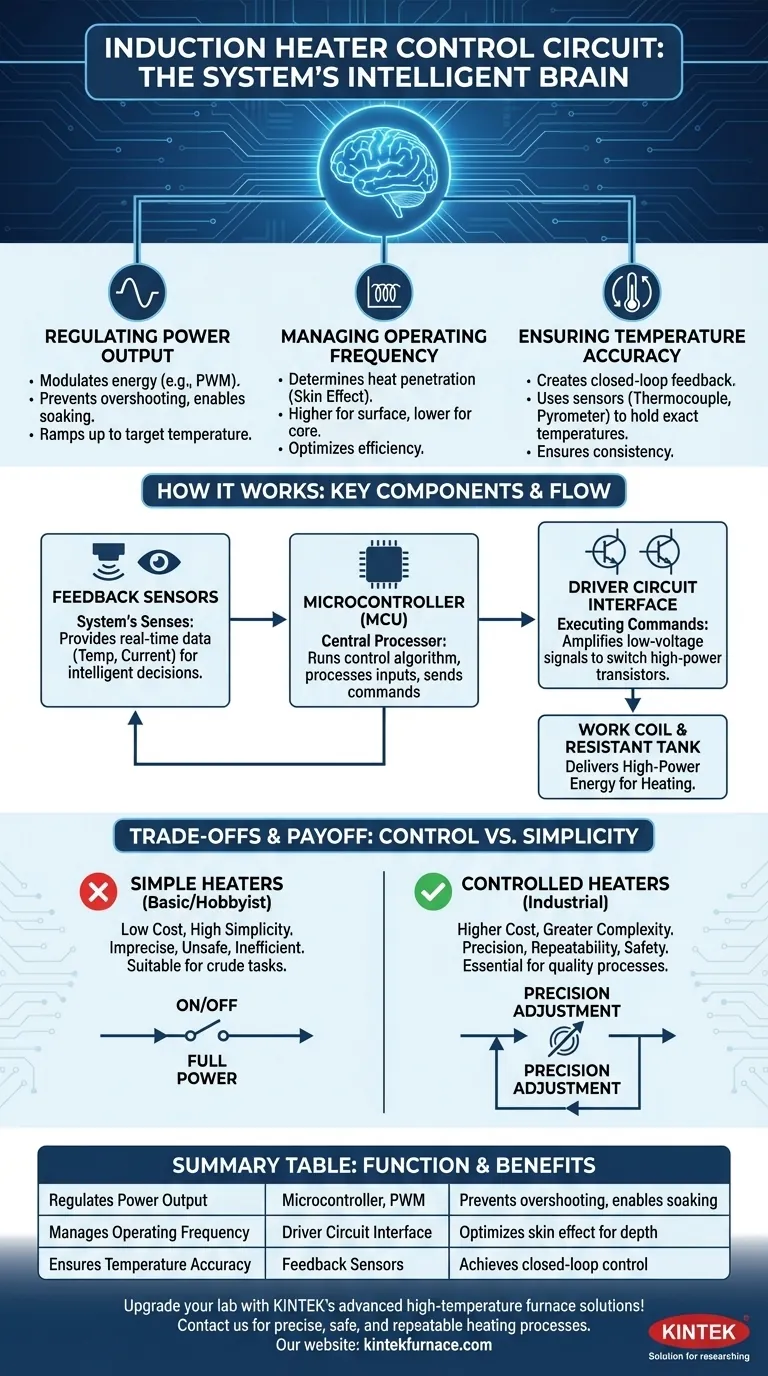

The Core Functions of the Control Circuit

An induction heater without control is like a car with the accelerator pinned to the floor—powerful but dangerously imprecise. The control circuit provides the necessary finesse by serving as the command layer between the user's intent and the high-power output.

Regulating Power Output

Not every task requires 100% of the heater's available power. The control circuit modulates the energy delivered to the work coil, often using techniques like Pulse Width Modulation (PWM).

This is critical for slowly ramping up to a target temperature without overshooting or for maintaining a specific temperature for an extended period, a process known as "soaking."

Managing Operating Frequency

The frequency of the alternating magnetic field determines how deeply the heat penetrates a conductive material—a phenomenon known as the "skin effect."

Higher frequencies concentrate heat near the surface, ideal for case hardening. Lower frequencies penetrate deeper, suitable for heating large billets through to the core. The control circuit sets and maintains the optimal frequency for the job and tunes the system for maximum electrical efficiency.

Ensuring Temperature Accuracy

This is perhaps the most critical function for industrial applications. The control circuit creates a closed-loop feedback system to achieve and hold exact temperatures.

It uses a sensor, such as a thermocouple touching the part or a non-contact infrared pyrometer, to measure the workpiece's actual temperature. It then compares this reading to the desired setpoint and automatically adjusts the power output to eliminate any difference, ensuring perfect accuracy.

How the Control Circuit Works: Key Components

The control circuit achieves its objectives through the coordinated action of several key electronic components.

The Microcontroller: The Central Processor

At the heart of any modern control circuit is a microcontroller (MCU) or a similar digital processor. This component runs the control algorithm—the software that dictates the heater's behavior.

The MCU processes inputs from the user (e.g., target temperature, heating time) and from feedback sensors. Based on this data, it calculates the necessary adjustments and sends commands to the driver circuit.

Feedback Sensors: The System's Senses

Sensors provide the real-time data the microcontroller needs to make intelligent decisions. Without them, the system is "open-loop," or flying blind.

Common sensors include thermocouples for direct contact temperature measurement and infrared pyrometers for non-contact measurement. Current sensors may also be used to monitor the power draw and protect the system from overloads.

The Driver Circuit Interface: Executing Commands

The control circuit does not directly handle the high power sent to the work coil. Instead, it sends low-voltage logic signals to a driver circuit.

The driver circuit acts as an intermediary, amplifying these small signals to precisely switch the high-power transistors (like IGBTs or MOSFETs) that deliver kilowatts of energy to the resonant tank and work coil.

Understanding the Trade-offs: Control vs. Simplicity

The level of control in an induction heater represents a direct trade-off between cost, complexity, and capability.

The Cost of Complexity

A sophisticated control circuit with a microcontroller, user interface, and multiple sensors adds significant cost and engineering complexity to the system. This requires both advanced hardware and robust software development.

The Limitations of Simple Heaters

Many basic, hobbyist-grade induction heaters (often based on a simple "ZVS" or Zero Voltage Switching driver) lack a true control circuit. They are essentially "on/off" devices that run at full power.

While cheap and easy to build, these heaters are imprecise, potentially unsafe, and inefficient. They are suitable for crude tasks like melting metal in a crucible but cannot perform controlled processes like heat treatment.

The Payoff: Precision and Repeatability

For any serious industrial application—such as brazing, forging, or annealing—a high-quality control circuit is non-negotiable.

It guarantees that every part is heated with the exact same thermal profile, ensuring consistent quality and predictable results. Furthermore, it enables critical safety interlocks, such as shutting down on over-temperature or detecting a missing workpiece.

Making the Right Choice for Your Goal

The necessary level of control is dictated entirely by your application's demand for precision, safety, and repeatability.

- If your primary focus is basic heating or melting for hobby projects: A simple, uncontrolled driver circuit may be sufficient and cost-effective for your needs.

- If your primary focus is repeatable industrial processes like brazing or heat treatment: A sophisticated control circuit with closed-loop temperature feedback is absolutely essential for quality control and safety.

- If your primary focus is maximizing efficiency across different part sizes and materials: A control circuit that can adjust operating frequency and tune the resonant tank will deliver the best performance and lowest energy consumption.

Ultimately, the control circuit is what transforms a raw power source into a precise and reliable manufacturing tool.

Summary Table:

| Function | Key Components | Benefits |

|---|---|---|

| Regulates Power Output | Microcontroller, PWM | Prevents overshooting, enables soaking |

| Manages Operating Frequency | Driver Circuit Interface | Optimizes skin effect for material depth |

| Ensures Temperature Accuracy | Feedback Sensors (e.g., thermocouples) | Achieves closed-loop control for consistency |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for efficient, safe, and repeatable processes. Contact us today to discuss how we can enhance your heating applications!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What are the main applications of vacuum hot pressing? Create Dense, Pure Materials for Demanding Industries

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- How is Vacuum Hot Press equipment used in R&D? Innovate with High-Purity Materials

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability