A high-performance dental vacuum porcelain furnace ensures restoration quality during multiple firing cycles by combining a vacuum environment with rigorous temperature control. By removing air pockets to increase density and managing heat fluctuations between 910°C and 995°C, the furnace prevents the deformation of metal frameworks while enhancing the esthetic properties of the porcelain.

The core of successful sintering lies in simultaneous densification and stabilization. The furnace must densify the porcelain to create translucency without warping the underlying metal structure, ensuring the final crown is both esthetically pleasing and mechanically sound.

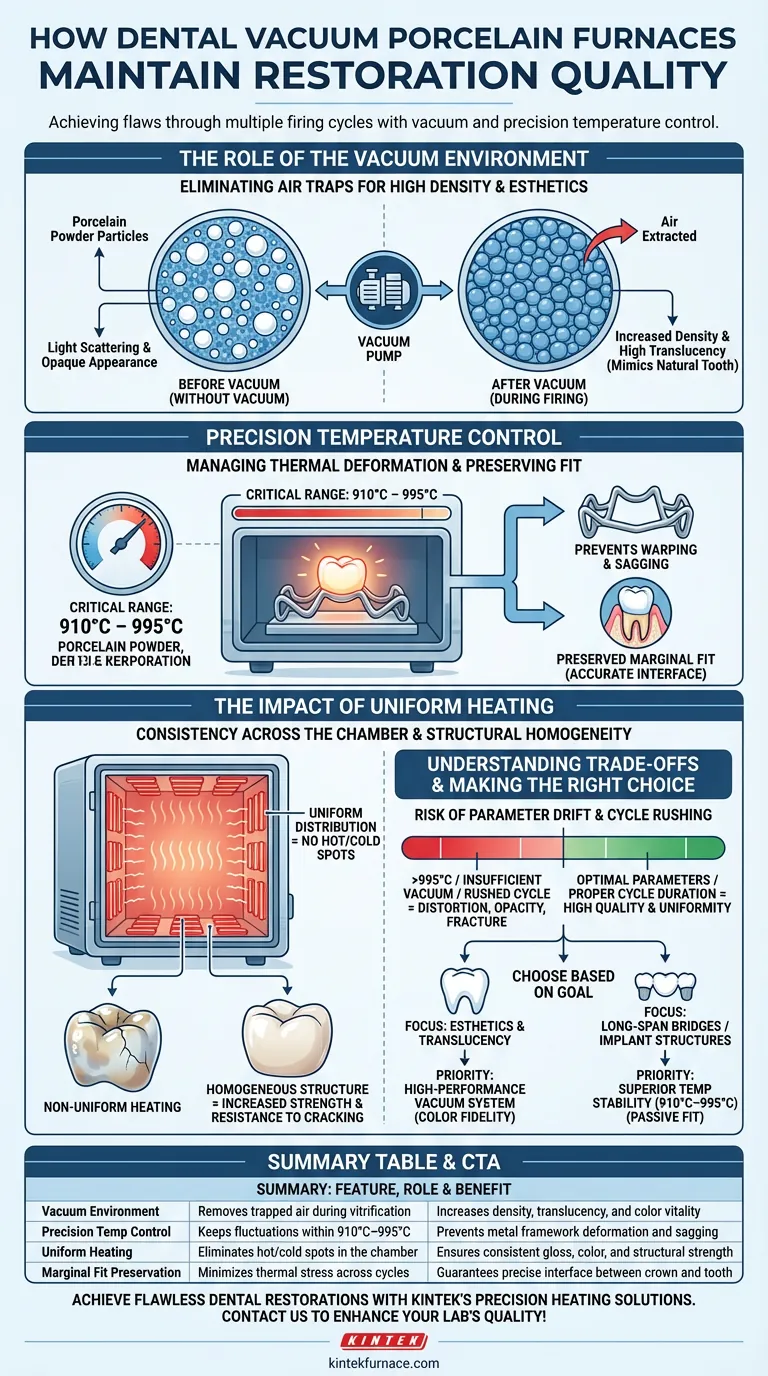

The Role of the Vacuum Environment

Eliminating Air Traps

During the firing process, air bubbles naturally form between porcelain powder particles.

If left unchecked, these microscopic bubbles scatter light, resulting in a restoration that looks opaque or chalky.

Enhancing Density and Esthetics

The furnace creates a vacuum environment specifically to extract this trapped air before the porcelain fully vitrifies.

This removal process significantly increases the density of the porcelain, resulting in the high translucency required to mimic natural tooth structure.

Precision Temperature Control

Managing Thermal Deformation

Repeated heating cycles pose a significant risk to the metal framework of a restoration, potentially causing it to warp or sag.

To combat this, high-performance furnaces utilize a precise temperature control system that strictly manages fluctuations, typically within the critical range of 910°C to 995°C.

Preserving Marginal Fit

By keeping temperatures within this specific tolerance, the furnace minimizes thermal stress on the metal substructure.

This ensures that the marginal fit—the precise interface between the restoration and the prepared tooth—remains accurate, even after multiple rounds of firing for oxidation, opaque, and body porcelain application.

The Impact of Uniform Heating

Consistency Across the Chamber

Beyond vacuum and temperature limits, the physical arrangement of heating elements plays a vital role.

A uniform distribution of these elements ensures consistent heat throughout the entire furnace chamber, preventing "cold spots" or "hot spots."

Preventing Color and Gloss Variations

Uniform heating is critical for esthetic consistency.

It ensures that different parts of the restoration sinter at the same rate, eliminating color differences and uneven gloss that can ruin the visual integration of the crown.

Structural Homogeneity and Strength

Consistent heat promotes uniform crystallization and densification of the porcelain material.

This results in a homogeneous internal structure, which enhances mechanical strength and makes the final restoration significantly more resistant to cracking and chipping.

Understanding the Trade-offs

The Risk of Parameter Drift

While these furnaces are designed for precision, reliance on strict parameters means that even minor calibration errors can be catastrophic.

If the temperature drifts above the 995°C ceiling, you risk framework distortion; if the vacuum pressure is insufficient, the porcelain will lack vitality and appear opaque.

Cycle Time vs. Quality

Achieving uniform heating and proper vacuum density requires specific, pre-set program durations.

Rushing these cycles to increase throughput often compromises the structural homogeneity, leading to latent internal stresses that may cause the ceramic to fracture post-seating.

Making the Right Choice for Your Goal

To select or operate a furnace effectively, align the machine's capabilities with your specific clinical priorities:

- If your primary focus is Esthetics and Translucency: Prioritize a unit with a high-performance vacuum system to ensure maximum air elimination and color fidelity.

- If your primary focus is Long-Span Bridges or Implant Structures: Prioritize a unit with superior temperature stability (910°C–995°C) to guarantee the metal framework maintains a passive fit.

Ultimately, the quality of a fired restoration is determined by the furnace's ability to maintain a stable environment where density increases while the physical shape remains absolute.

Summary Table:

| Feature | Role in Quality Maintenance | Benefit for Restorations |

|---|---|---|

| Vacuum Environment | Removes trapped air during vitrification | Increases density, translucency, and color vitality |

| Precision Temp Control | Keeps fluctuations within 910°C–995°C | Prevents metal framework deformation and sagging |

| Uniform Heating | Eliminates hot/cold spots in the chamber | Ensures consistent gloss, color, and structural strength |

| Marginal Fit Preservation | Minimizes thermal stress across cycles | Guarantees precise interface between crown and tooth |

Achieve flawless dental restorations with KINTEK’s precision heating solutions. Backed by expert R&D and manufacturing, KINTEK offers advanced vacuum systems and lab high-temp furnaces—including Muffle, Tube, Rotary, and CVD systems—all customizable for your unique laboratory needs. Whether you prioritize high-translucency esthetics or the structural integrity of long-span bridges, our technology ensures absolute stability through every firing cycle. Contact KINTEK today to enhance your lab’s efficiency and output quality!

Visual Guide

References

- Rashin Giti, Pardis Farrahi. Marginal fit of 3-unit implant-supported fixed partial dentures: Influence of pattern fabrication method and repeated porcelain firings. DOI: 10.1371/journal.pone.0301799

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are common maintenance tasks for a zirconia sintering furnace? Ensure Precision and Longevity for Your Lab

- How to use a dental furnace? Master the Thermal Cycle for Perfect Restorations

- What problems does overloading a dental furnace cause? Avoid Costly Failures and Ensure Quality

- What are the effects of using improper sintering temperatures on ceramic dental restorations? Avoid Premature Failure and Ensure Clinical Success

- What safety features should a sintering furnace have? Ensure Maximum Protection for Your Lab

- What temperature range is typically required for sintering zirconia in dental furnaces? Achieve Dense, Strong Dental Restorations

- What are combined firing/pressing furnaces used for? Boost Dental Lab Efficiency with Dual-Function Furnaces

- What function does a vacuum ceramic furnace perform during the glazing process of lithium disilicate? Professional Guide