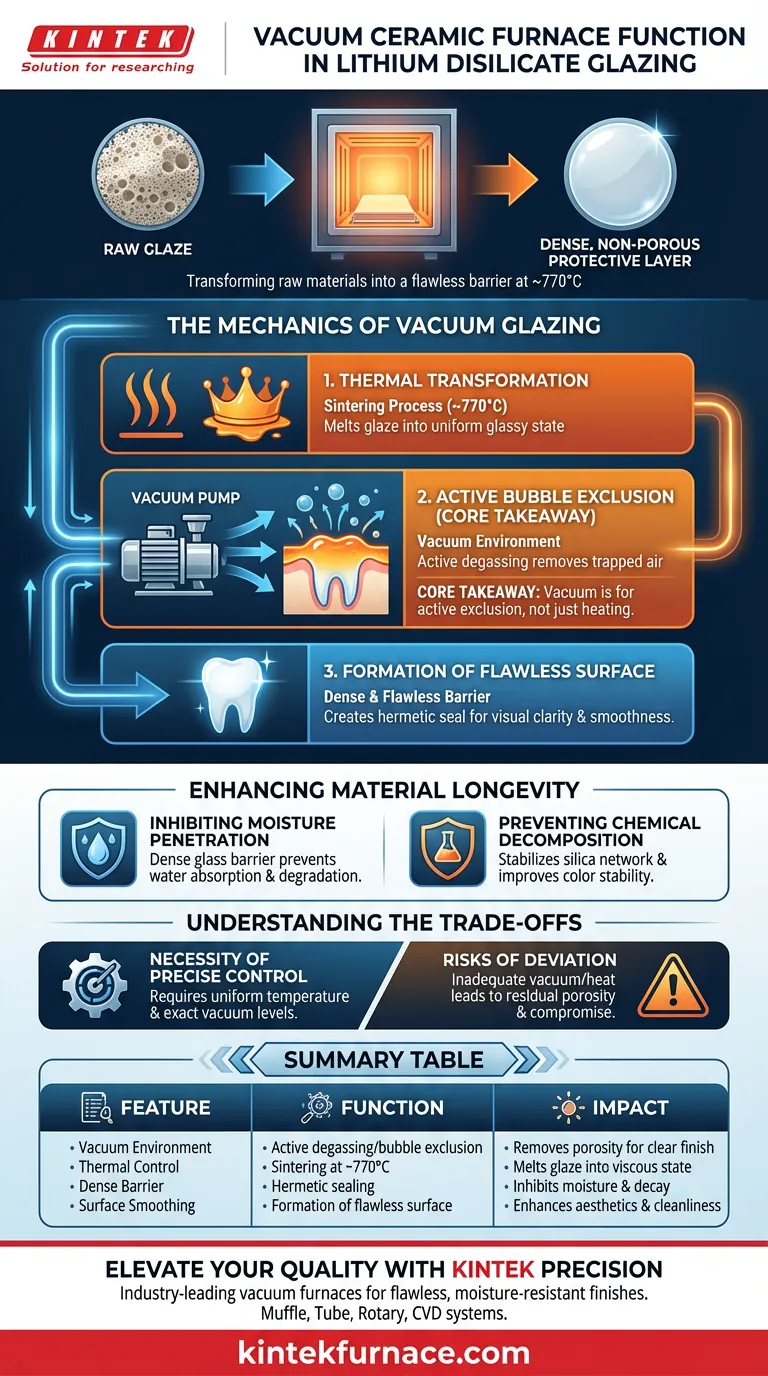

A vacuum ceramic furnace performs the critical function of transforming raw glaze materials into a dense, non-porous protective layer on lithium disilicate restorations. By heating the material to specific temperatures (typically 770°C) under a vacuum, the furnace actively extracts air bubbles from the molten glaze, creating a hermetic seal that improves both the visual clarity and the structural longevity of the material.

Core Takeaway The vacuum environment is not merely for heating; its primary purpose is the active exclusion of trapped air during the sintering phase. This ensures the final glaze is a dense, flawless barrier that prevents moisture penetration and chemical decomposition, rather than a porous coating that could compromise the restoration over time.

The Mechanics of Vacuum Glazing

Thermal Transformation

The furnace utilizes specific heating programs to raise the temperature of the lithium disilicate and the applied glaze paste.

At approximately 770 degrees Celsius, the furnace triggers a sintering process. This heat transforms the glaze powder and liquid mixture, melting them down into a uniform, viscous glassy state.

Active Bubble Exclusion

The defining feature of this process is the application of a vacuum during the heating cycle.

As the glaze melts, air trapped within the powder/liquid mixture attempts to escape. The vacuum environment facilitates this degassing process, effectively pulling air bubbles out of the molten layer before it solidifies.

Formation of a Flawless Surface

By removing these microscopic voids, the furnace produces a dense and flawless barrier.

Without the vacuum, the glaze layer would likely contain trapped porosity, which results in a cloudy appearance and a rougher surface texture. The vacuum ensures the final finish is smooth and optically clear.

Enhancing Material Longevity

Inhibiting Moisture Penetration

The glazed layer acts as a functional shield for the underlying lithium disilicate.

The dense glass barrier created by the vacuum furnace inhibits moisture penetration. This is critical because water absorption can degrade the ceramic structure over prolonged exposure in the oral environment.

Preventing Chemical Decomposition

Beyond moisture, the glaze protects the chemical integrity of the material.

The barrier prevents the decomposition of the silica network. By stabilizing the surface chemistry, the glazing process significantly improves the color stability of the restoration, ensuring it does not degrade or shift in shade over time.

Understanding the Trade-offs

The Necessity of Precise Control

While the vacuum is essential for density, the process relies heavily on the precision of the thermal field.

Just as high-temperature furnaces used in material synthesis require strict execution of heating curves to prevent local overheating, the glazing furnace must maintain uniform temperature distribution.

Risks of Process Deviation

If the temperature fluctuates or the vacuum level is insufficient, the glaze may fail to seal completely.

Inadequate vacuum levels can lead to residual porosity, compromising the hermetic seal. Conversely, incorrect thermal application can cause compositional deviations, negating the benefits of the glaze layer.

Making the Right Choice for Your Goal

To maximize the quality of lithium disilicate restorations, consider how the furnace functions relative to your specific objectives:

- If your primary focus is Aesthetic Quality: Ensure the vacuum cycle is fully synchronized with the melt phase to eliminate all micro-bubbles, guaranteeing high translucency and color fidelity.

- If your primary focus is Long-Term Durability: Prioritize the integrity of the sintered barrier (holding at 770°C) to create a maximum-density shield against moisture and silica degradation.

Ultimately, the vacuum ceramic furnace converts a cosmetic coating into a functional, structural defense system for the restoration.

Summary Table:

| Feature | Function in Glazing Process | Impact on Lithium Disilicate |

|---|---|---|

| Vacuum Environment | Active degassing/bubble exclusion | Removes porosity for a clear, dense finish |

| Thermal Control | Sintering at ~770°C | Melts glaze into a uniform, viscous glassy state |

| Dense Barrier | Hermetic sealing | Inhibits moisture penetration & chemical decay |

| Surface Smoothing | Formation of flawless surface | Enhances aesthetics and prevents plaque buildup |

Elevate Your Restoration Quality with KINTEK Precision

Don't let residual porosity compromise your lab's output. KINTEK provides industry-leading vacuum and high-temperature furnace systems—including Muffle, Tube, Rotary, and CVD systems—specifically engineered for the precise thermal control and vacuum integrity required for lithium disilicate glazing. Backed by expert R&D and manufacturing, our customizable furnaces ensure every restoration achieves a flawless, moisture-resistant finish.

Ready to optimize your dental laboratory workflow? Contact our specialists today to find the perfect high-temp solution for your unique needs!

Visual Guide

References

- K. Saleh, Yasser Aly. COLOR STABILITY OF GLAZED AND POLISHED LITHIUM DISILICATE PRESSABLE GLASS CERAMIC AFTER IMMERSION IN MOUTH RINSES: AN IN VITRO STUDY.. DOI: 10.21608/adjalexu.2023.212029.1387

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the program stages in zirconia sintering furnaces and their functions? Master Precision for Durable Dental Restorations

- What additional features might a porcelain furnace have for esthetic enhancements? Unlock Superior Dental Restoration Control

- What happens to the restoration inside the porcelain furnace? Discover the Sintering Process for Durable Dental Ceramics

- Can a porcelain furnace be used for zirconia materials? Understand the critical differences for success.

- What are the limitations of ceramic dental furnaces? Specialized for Porcelain, Not Zirconia

- How many teeth can the sintering tray of the Zirconia Dental Sintering Furnace accommodate? Boost Your Lab's Efficiency with High-Capacity Sintering

- What temperature range do pressing furnaces typically operate at? Optimize Your Dental Lab's Ceramic Pressing

- What is the significance of biocompatibility in dental ceramics processed by a porcelain furnace? Ensure Patient Safety and Long-Term Oral Health