In short, the primary features a porcelain furnace adds for esthetic enhancements are those that facilitate the precise application and firing of stains and glazes. However, the true esthetic potential of a restoration is unlocked not by a single feature, but by a suite of technical capabilities that grant the technician absolute control over the ceramic firing process.

The ability to apply stains and glazes is the most direct esthetic feature, but superior esthetics are fundamentally achieved through the furnace's core capacity for precise, repeatable, and uniform control over temperature and atmosphere.

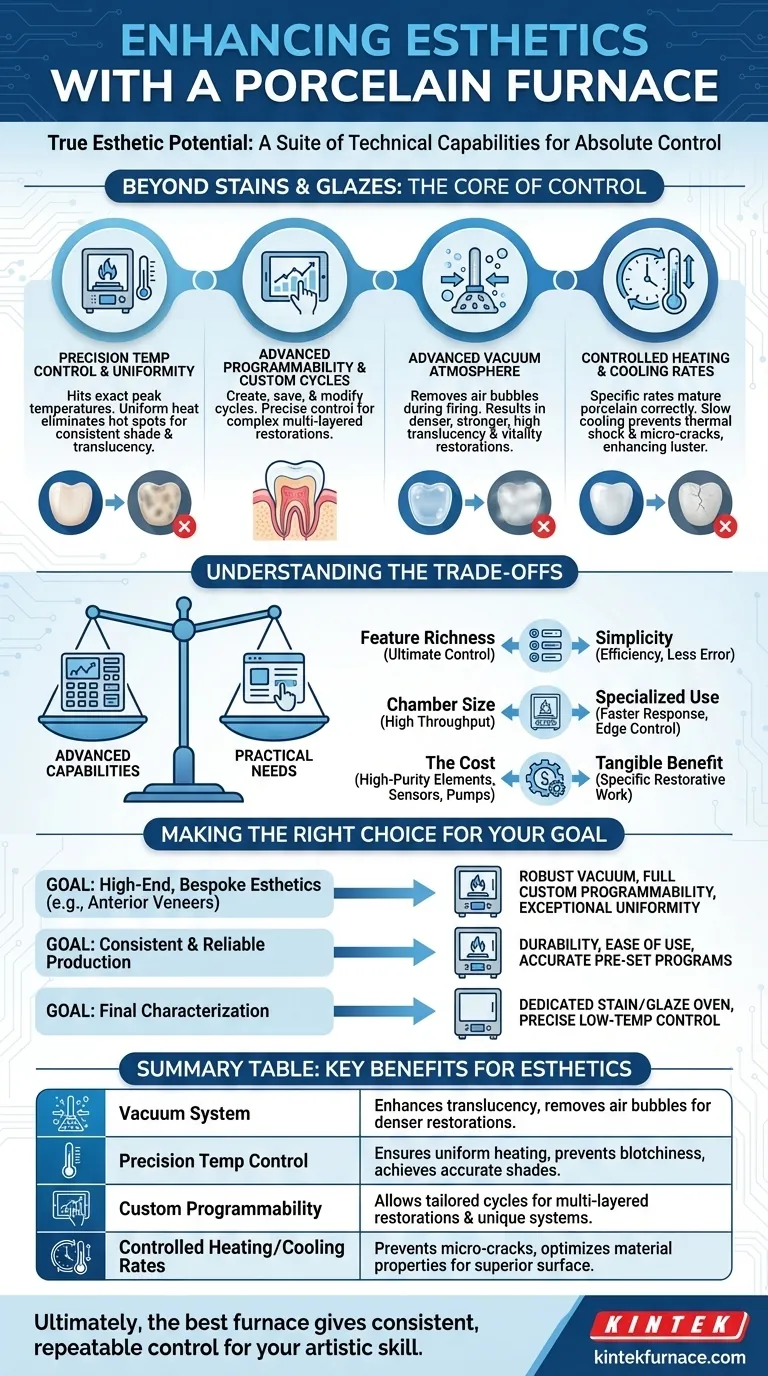

Beyond Stains and Glazes: The Core of Esthetic Control

While a dedicated "stain and glaze" cycle is a clear esthetic feature, several foundational technical capabilities have a far greater impact on the final look of a restoration. These features ensure the ceramic achieves its ideal properties of translucency, color value, and surface texture.

Precision Temperature Control and Uniformity

The final shade and translucency of a ceramic are critically dependent on hitting exact peak temperatures. A furnace with high-end temperature controllers and strategically placed heating elements (often molybdenum disilicide) ensures this precision.

Uniform heat distribution is just as important. It eliminates "hot spots" within the firing chamber, preventing uneven vitrification that can lead to a blotchy or opaque appearance in the final restoration.

Advanced Programmability and Custom Cycles

Modern furnaces go far beyond simple pre-set programs. The ability for a technician to create, save, and modify custom firing cycles via a user-friendly touchscreen is a powerful esthetic tool.

This allows for precise control over every stage of the process, accommodating the unique requirements of different ceramic systems, custom-mixed porcelains, or complex multi-layered restorations with internal characterization.

Advanced Firing Chamber Atmosphere (Vacuum)

Many high-end furnaces incorporate a vacuum pump. During the firing cycle, this pump removes air from the firing chamber.

This process pulls microscopic air bubbles out of the porcelain particles before they sinter. The result is a denser, stronger restoration with significantly higher translucency and vitality, which is a cornerstone of high-end esthetics.

Controlled Heating and Cooling Rates

The speed at which a furnace heats up and cools down has a major effect on the final outcome. The ability to program a specific heating rate (e.g., 60°C per minute) is crucial for maturing different types of porcelain correctly.

Likewise, a slow, controlled cooling phase prevents thermal shock, which can cause micro-cracks that compromise both the strength and the surface luster of the restoration.

Understanding the Trade-offs

Investing in a furnace requires balancing advanced capabilities with practical needs. Not every feature is necessary for every lab.

Feature Richness vs. Simplicity

A furnace with hundreds of programmable slots and advanced calibration options offers ultimate control. However, this complexity can be overwhelming and unnecessary for a lab that primarily uses one or two consistent ceramic systems.

For many, a furnace with a handful of reliable pre-set programs and an intuitive interface offers greater efficiency and less room for user error.

Chamber Size vs. Specialized Use

A large firing chamber allows for higher throughput, which is essential for a production-oriented lab.

However, a smaller chamber often heats more uniformly and responds faster to temperature changes, potentially offering a slight edge in control for highly demanding, single-unit anterior esthetic cases.

The Cost of Ultimate Control

Features like high-purity quartz-coiled heating elements, multi-point temperature sensors, and powerful vacuum pumps directly contribute to a higher price tag.

You must weigh the cost of these features against the tangible benefit they provide for the specific type of restorative work you perform. A simple glaze oven is far more cost-effective than a full-featured ceramic furnace if that is its only purpose.

Making the Right Choice for Your Goal

Your decision should be guided by the primary esthetic goal of your work.

- If your primary focus is high-end, bespoke esthetics (e.g., anterior veneers): Prioritize a furnace with a robust vacuum system, full custom programmability, and a reputation for exceptional temperature uniformity.

- If your primary focus is consistent and reliable production: Choose a furnace known for its durability, ease of use, and accurate pre-set programs for the most common materials you use.

- If your primary focus is simply final characterization: A smaller, dedicated stain and glaze oven with precise low-temperature control is the most efficient and cost-effective solution.

Ultimately, the best furnace is the one that gives you the consistent and repeatable control needed to translate your artistic skill into the final restoration.

Summary Table:

| Feature | Key Benefit for Esthetics |

|---|---|

| Vacuum System | Enhances translucency by removing air bubbles for denser, more vital restorations |

| Precision Temperature Control | Ensures uniform heating to prevent blotchiness and achieve accurate shades |

| Custom Programmability | Allows tailored cycles for multi-layered restorations and unique ceramic systems |

| Controlled Heating/Cooling Rates | Prevents micro-cracks and optimizes material properties for superior surface finish |

Elevate your dental lab's esthetic outcomes with KINTEK's advanced porcelain furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs for consistent, high-quality restorations. Contact us today to discuss how our furnaces can enhance your control and results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision