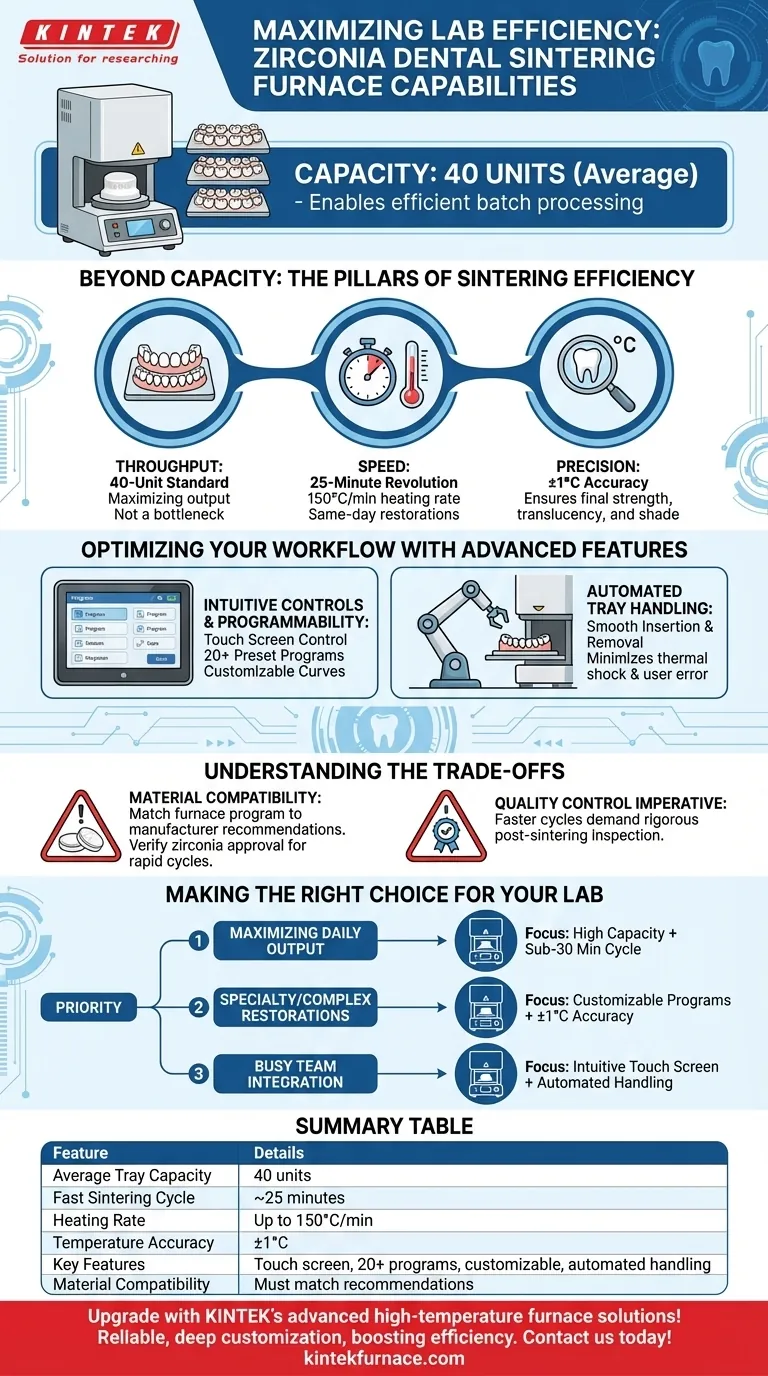

On average, a standard zirconia dental sintering furnace tray can accommodate approximately 40 units of teeth. This capacity allows for efficient batch processing in a typical dental lab environment. However, the number of units is only one part of a much larger equation that determines a furnace's true value and impact on your workflow.

The central consideration is not simply how many teeth a furnace can hold, but how quickly and accurately it can process them. The combination of capacity, speed, and precision is what truly defines the efficiency and profitability of a modern dental lab's restoration process.

Beyond Capacity: The Pillars of Sintering Efficiency

While the 40-unit capacity provides a baseline for throughput, two other factors—speed and precision—are critical for evaluating the performance of a modern zirconia furnace.

Throughput: The 40-Unit Standard

A capacity of 40 units is a robust standard for most dental lab operations. It enables the processing of multiple cases simultaneously, maximizing the output of a single sintering cycle.

This batch size is designed to align with a typical day's production, ensuring that the furnace is a facilitator, not a bottleneck, in your workflow.

Speed: The 25-Minute Revolution

The most significant advancement in recent years is the dramatic reduction in cycle times. Modern fast-sintering furnaces can complete a full cycle in as little as 25 minutes.

This is made possible by remarkable heating rates, with some models capable of reaching target temperatures at 150°C per minute. This speed transforms workflow, allowing for same-day restorations and rapid turnaround on urgent cases.

Precision: The Critical Role of ±1°C Accuracy

Speed is meaningless without precision. Zirconia's final strength, translucency, and shade are highly dependent on an exact sintering temperature profile.

A furnace with a temperature accuracy of ±1°C ensures that the material's properties are fully and consistently realized. This level of control is non-negotiable for producing high-quality, predictable restorations and avoiding costly remakes.

Optimizing Your Workflow with Advanced Features

Modern furnaces are not just ovens; they are sophisticated instruments designed to enhance consistency and reduce user error.

Intuitive Controls and Programmability

Features like an intuitive touch screen control and 20 or more preset heating programs significantly lower the learning curve for technicians.

The ability to create and save customizable sintering curves gives labs the flexibility to work with a wide range of zirconia materials from different manufacturers, each with its own specific requirements.

Automated Tray Handling

Automated tray handling is another key feature that boosts efficiency. It ensures the smooth and safe insertion and removal of the sintering tray, minimizing the risk of thermal shock to the restorations or operator error.

Understanding the Trade-offs

While the benefits of fast sintering are clear, it is essential to approach this technology with a complete understanding of its requirements.

The Material Compatibility Question

Not all zirconia discs are formulated for ultra-fast sintering cycles. Using a material not certified for rapid heating can compromise the structural integrity and aesthetic quality of the final restoration.

It is absolutely critical to match the furnace's sintering program with the material manufacturer's specific recommendations. Always verify that your chosen zirconia is approved for the cycle you intend to use.

The Quality Control Imperative

Faster cycles demand equally fastidious quality control. With quicker turnaround, it becomes even more important to have a rigorous process for inspecting restorations post-sintering to ensure they meet all clinical and aesthetic standards.

Making the Right Choice for Your Lab

Selecting the right furnace depends on balancing your lab's specific priorities.

- If your primary focus is maximizing daily output: Prioritize a furnace that combines the 40-unit capacity with a verified sub-30-minute sintering cycle to achieve the highest throughput.

- If your primary focus is specialty or complex restorations: Focus on furnaces with highly customizable heating programs and proven ±1°C accuracy to ensure absolute material integrity.

- If your primary focus is integrating a furnace into a busy team: Look for models with intuitive touch screens, extensive preset programs, and automated handling to minimize training and user error.

By understanding the interplay between capacity, speed, and precision, you can select a furnace that not only meets your needs but elevates your lab's capabilities.

Summary Table:

| Feature | Details |

|---|---|

| Average Tray Capacity | 40 units of teeth |

| Fast Sintering Cycle Time | As little as 25 minutes |

| Heating Rate | Up to 150°C per minute |

| Temperature Accuracy | ±1°C |

| Key Features | Touch screen controls, 20+ preset programs, customizable sintering curves, automated tray handling |

| Material Compatibility | Requires matching zirconia discs with manufacturer recommendations |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable sintering furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, boosting efficiency and profitability. Contact us today to discover how our tailored solutions can elevate your restoration process!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations