At their core, dental sintering and porcelain furnaces are defined by their temperature capabilities, process control, and material compatibility. Key features across both types include precise, programmable firing cycles, intuitive touch-screen controls for ease of use, and uniform heat distribution within the chamber to ensure consistent results. The most significant distinction lies in their maximum temperature, which dictates the specific materials each furnace is designed to process.

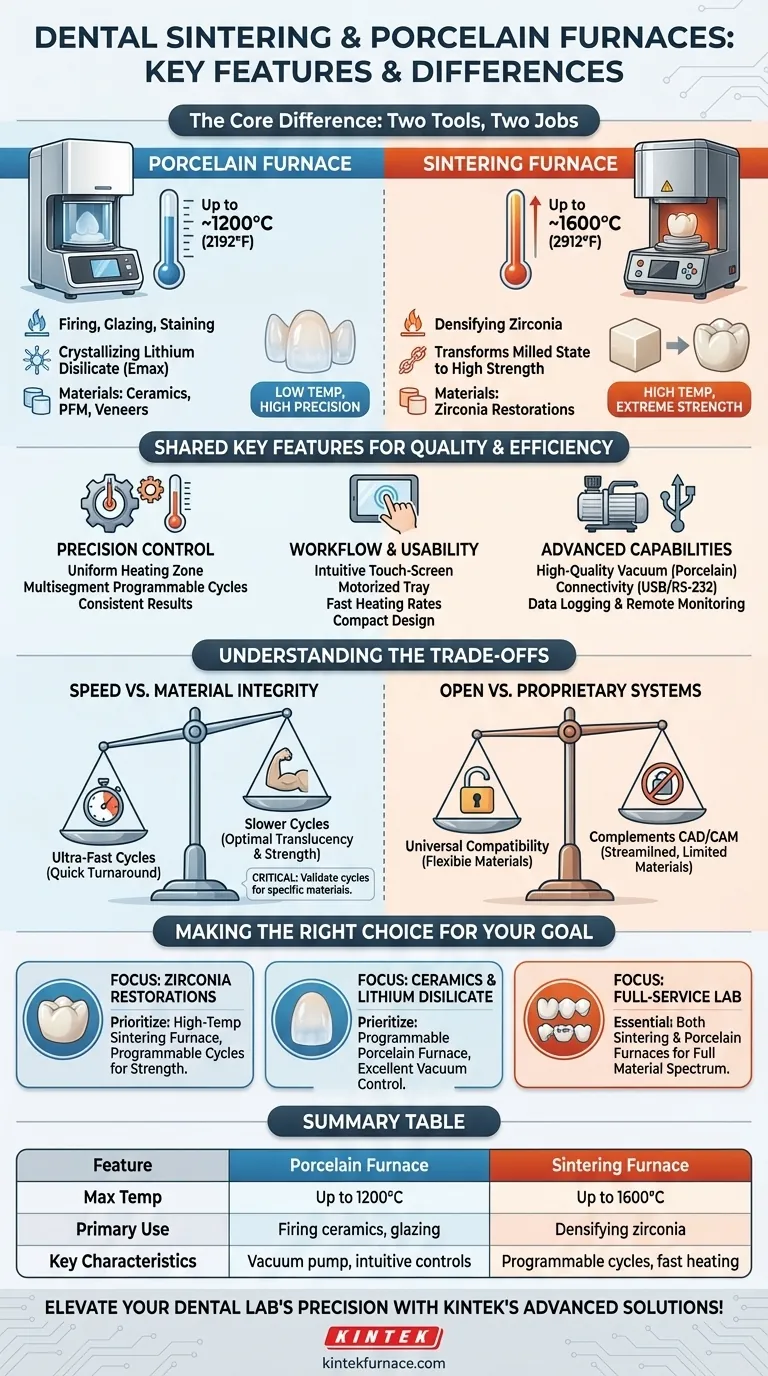

The central takeaway is that porcelain and sintering furnaces serve two distinct, non-interchangeable functions. Porcelain furnaces fire and glaze ceramics at temperatures up to ~1200°C, while sintering furnaces use much higher heat (up to ~1600°C) specifically to transform milled zirconia into its final, high-strength state.

The Core Difference: Sintering vs. Porcelain

Before evaluating specific features, it is crucial to understand that these are two different tools for two different jobs. A lab processing modern materials will often need both.

The Role of a Porcelain Furnace

A porcelain furnace is designed for firing, glazing, and staining various dental ceramics. This includes traditional porcelain-fused-to-metal (PFM) restorations as well as all-ceramic materials.

These electronically controlled devices are essential for crystallizing materials like lithium disilicate (e.g., Emax) and firing veneers or inlays. They operate with high precision at a lower maximum temperature, typically up to 1200°C (2192°F).

The Role of a Sintering Furnace

A sintering furnace serves one primary purpose: to sinter zirconia. After a zirconia restoration is milled, it exists in a soft, chalk-like state.

The sintering furnace subjects this pre-sintered restoration to extremely high temperatures—often up to 1600°C (2912°F)—over a programmed cycle. This process densifies the material, shrinking it to its final size and imparting the incredible strength for which zirconia is known.

Key Features for Quality and Efficiency

Once you know which type of furnace you need, you can evaluate the features that directly impact the quality of your restorations and the efficiency of your workflow.

Precision Temperature Control

This is the single most important characteristic of any dental furnace. Inconsistent heat leads to weak or unaesthetic restorations.

Key features include a uniform heating zone to ensure all parts of the restoration receive the same temperature and a multisegment programmable controller. This allows you to create custom heating, holding, and cooling cycles to perfectly match the specifications of different materials.

Workflow and Usability

Modern furnaces are designed to simplify what was once a complex process. Look for an intuitive, color touch-screen display that makes programming cycles straightforward.

Features like a motorized tray ensure smooth, repeatable placement of the work, while fast heating rates can significantly reduce overall processing time, increasing lab throughput. A compact design is also a valuable feature in labs where space is at a premium.

Advanced Capabilities

For porcelain furnaces, a high-quality vacuum pump is essential. Pulling a vacuum during the firing cycle removes air to reduce porosity in the final ceramic, resulting in a stronger and more aesthetic restoration.

For both types, connectivity options like USB ports or RS-232 communication allow for easy data logging, program transfer, and remote monitoring, which helps with quality control and troubleshooting.

Understanding the Trade-offs

Choosing a furnace involves balancing competing priorities. Understanding these trade-offs will help you make a more informed decision.

Speed vs. Material Integrity

Many modern sintering furnaces offer "speed" or "fast" sintering cycles that can be completed in a fraction of the traditional time. While this drastically improves turnaround, it can be a compromise.

For some zirconia materials, ultra-fast cycles may result in slightly lower translucency or even reduced flexural strength compared to a slower, longer cycle. It is critical to ensure your chosen cycle is validated for the specific zirconia you are using.

Open vs. Proprietary Systems

Some furnaces are designed as part of a complete ecosystem, intended to complement specific CAD/CAM systems like CEREC or inLab. These often offer streamlined workflows but may be optimized for a limited range of materials.

"Open-system" furnaces are designed to be universally compatible, giving you the flexibility to use materials from any manufacturer. This provides more freedom but may require more effort to develop and validate firing programs.

Making the Right Choice for Your Goal

Your decision should be driven entirely by the materials you work with most often.

- If your primary focus is zirconia restorations: Prioritize a high-temperature sintering furnace with precise, programmable cycles to achieve optimal strength and aesthetics.

- If your primary focus is lithium disilicate or feldspathic porcelain: A programmable porcelain furnace with excellent vacuum control is the essential tool for achieving high-quality, non-porous results.

- If you operate a full-service lab: You will almost certainly need both a sintering furnace and a porcelain furnace to efficiently handle the full spectrum of modern dental materials.

Matching the furnace's technical capabilities to your primary materials is the most critical step toward producing predictable, high-quality dental restorations.

Summary Table:

| Feature | Porcelain Furnace | Sintering Furnace |

|---|---|---|

| Max Temperature | Up to 1200°C | Up to 1600°C |

| Primary Use | Firing ceramics, glazing | Densifying zirconia |

| Key Characteristics | Vacuum pump, intuitive controls | Programmable cycles, fast heating |

Elevate your dental lab's precision and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for sintering and porcelain applications. Contact us today to discuss how our solutions can enhance your workflow and deliver consistent, high-quality restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations