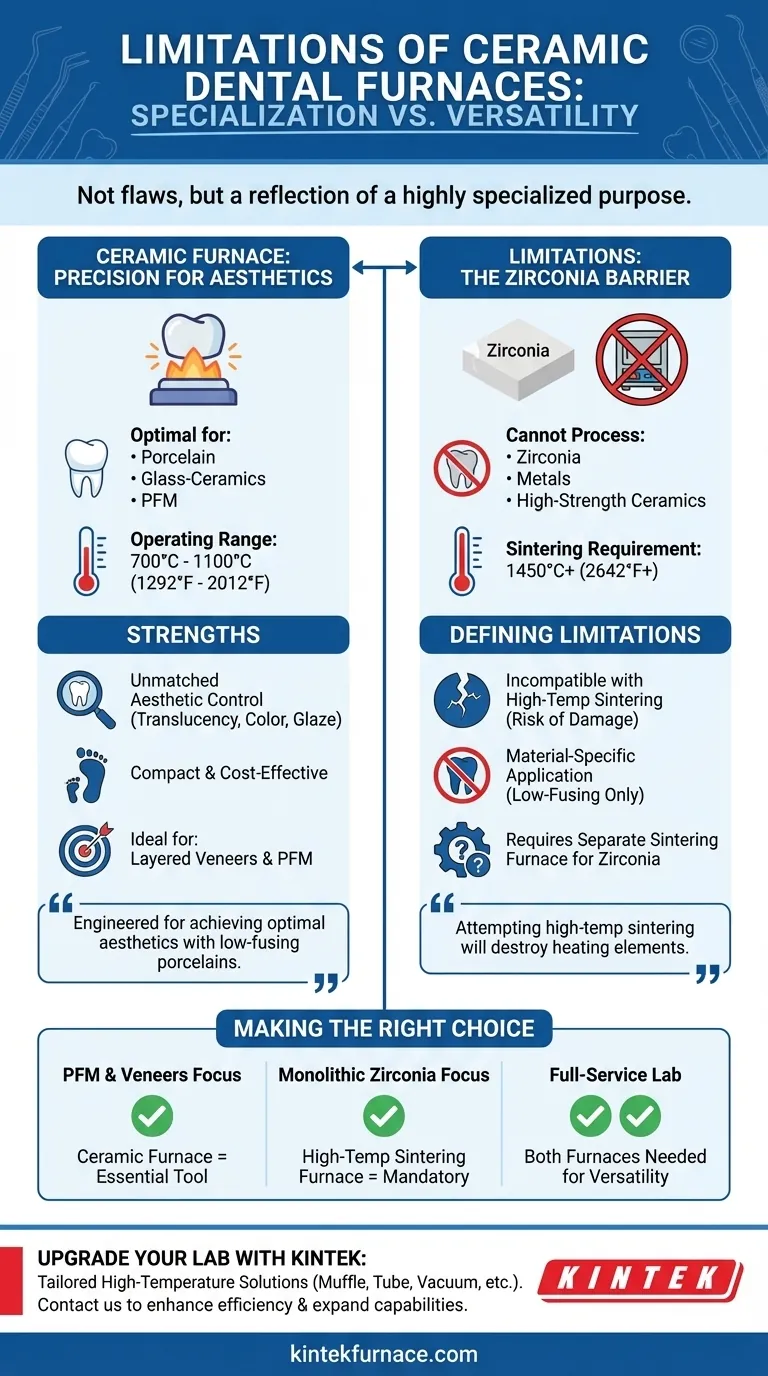

In short, the primary limitations of ceramic dental furnaces are their inability to perform high-temperature sintering and their specialization for only specific ceramic materials. These furnaces are precision instruments designed for the unique firing requirements of porcelain and glass-ceramics, not for high-strength materials like zirconia that demand much higher processing temperatures.

A ceramic furnace’s limitations are not flaws, but rather a reflection of its highly specialized purpose. It is a tool engineered for achieving optimal aesthetics with low-fusing porcelains, not a universal oven for all dental materials.

The Core Design: Precision Over Power

A ceramic furnace is not simply a hot box; it is a finely tuned instrument designed to achieve one goal with exceptional accuracy: creating lifelike dental restorations from porcelain.

Built for Aesthetics, Not Brute Force

The primary function of a ceramic furnace is to fire materials like porcelain crowns, veneers, and porcelain-fused-to-metal (PFM) restorations. Its design prioritizes uniform heating and extremely accurate temperature control to achieve the ideal translucency, color matching, and glaze for a flawless aesthetic result.

The Temperature Ceiling

Ceramic furnaces typically operate in a temperature range of 700°C to 1100°C (1292°F to 2012°F). This range is perfectly suited for fusing layers of porcelain but is far too low for processing other materials.

The Role of Heating Elements

This temperature limitation is a direct result of their components. Ceramic furnaces use heating elements made of materials like Kanthal or Nichrome, which are reliable and cost-effective within their intended operational range. They are not designed to withstand the extreme heat required for sintering.

The Two Defining Limitations Explained

Understanding these design principles clarifies the two fundamental limitations of any standard ceramic dental furnace.

Limitation 1: Incompatibility with High-Temperature Sintering

The most significant limitation is the inability to sinter high-strength ceramics like zirconia. Sintering is a process that transforms a porous, "chalky" pre-milled restoration into a dense, strong final product.

Zirconia requires sintering temperatures of 1450°C (2642°F) or higher to achieve its full structural integrity. Attempting this in a ceramic furnace would not only fail to process the material but would also destroy the furnace's heating elements.

Limitation 2: Material-Specific Application

A ceramic furnace is restricted to firing low-fusing conventional ceramics and glass-ceramics. It cannot be used to process metals or high-strength crystalline ceramics. This makes it a specialized tool rather than a versatile, all-in-one solution for a modern dental lab.

Understanding the Trade-offs: Specialization vs. Versatility

Choosing a furnace involves balancing its capabilities against your lab's or practice's specific needs. The ceramic furnace presents a clear set of trade-offs.

What You Gain: Unmatched Aesthetic Control

The key advantage is precision. By focusing on a lower temperature range, these furnaces provide the exceptional control needed to layer porcelain and achieve natural-looking gradients, opalescence, and surface texture.

What You Sacrifice: Material Versatility

The clear downside is the inability to work with zirconia, which is a dominant material in modern restorative dentistry for its strength. A lab that wants to produce zirconia restorations in-house must invest in a separate, high-temperature sintering furnace.

The Cost and Footprint Advantage

Ceramic furnaces are generally more cost-effective and have a more compact, user-friendly design compared to the larger, more industrial sintering furnaces. For a practice focusing exclusively on porcelain work, it is the more economical and practical choice.

Making the Right Choice for Your Goal

Your decision must be driven by the types of restorations you produce. The "limitation" of a ceramic furnace only becomes a problem when it is mismatched with the task at hand.

- If your primary focus is on porcelain-fused-to-metal (PFM) and layered aesthetic veneers: A ceramic furnace is the essential, purpose-built tool for your work.

- If your practice is heavily involved with monolithic zirconia crowns and bridges: You absolutely require a separate, high-temperature sintering furnace to process these materials correctly.

- If you run a full-service lab handling a wide range of materials: You will need both types of furnaces to meet the distinct processing requirements of different ceramics.

Understanding these distinctions ensures you invest in the right technology, preventing costly errors and maximizing the quality of your final restorations.

Summary Table:

| Limitation | Description | Impact on Dental Labs |

|---|---|---|

| Inability to perform high-temperature sintering | Cannot reach temperatures above 1100°C, required for zirconia sintering | Labs must invest in separate sintering furnaces for zirconia restorations |

| Material-specific application | Designed only for low-fusing ceramics like porcelain and glass-ceramics | Limits versatility, not suitable for metals or high-strength ceramics |

Upgrade Your Dental Lab with KINTEK's Advanced Furnace Solutions

Are you struggling with the limitations of your current ceramic furnace? KINTEK specializes in providing tailored high-temperature furnace solutions to meet your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely address your specific experimental and production requirements, whether you're working with porcelain, zirconia, or other advanced materials.

Don't let equipment hold back your lab's potential—contact us today to discuss how our solutions can enhance your efficiency and expand your material processing capabilities!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations