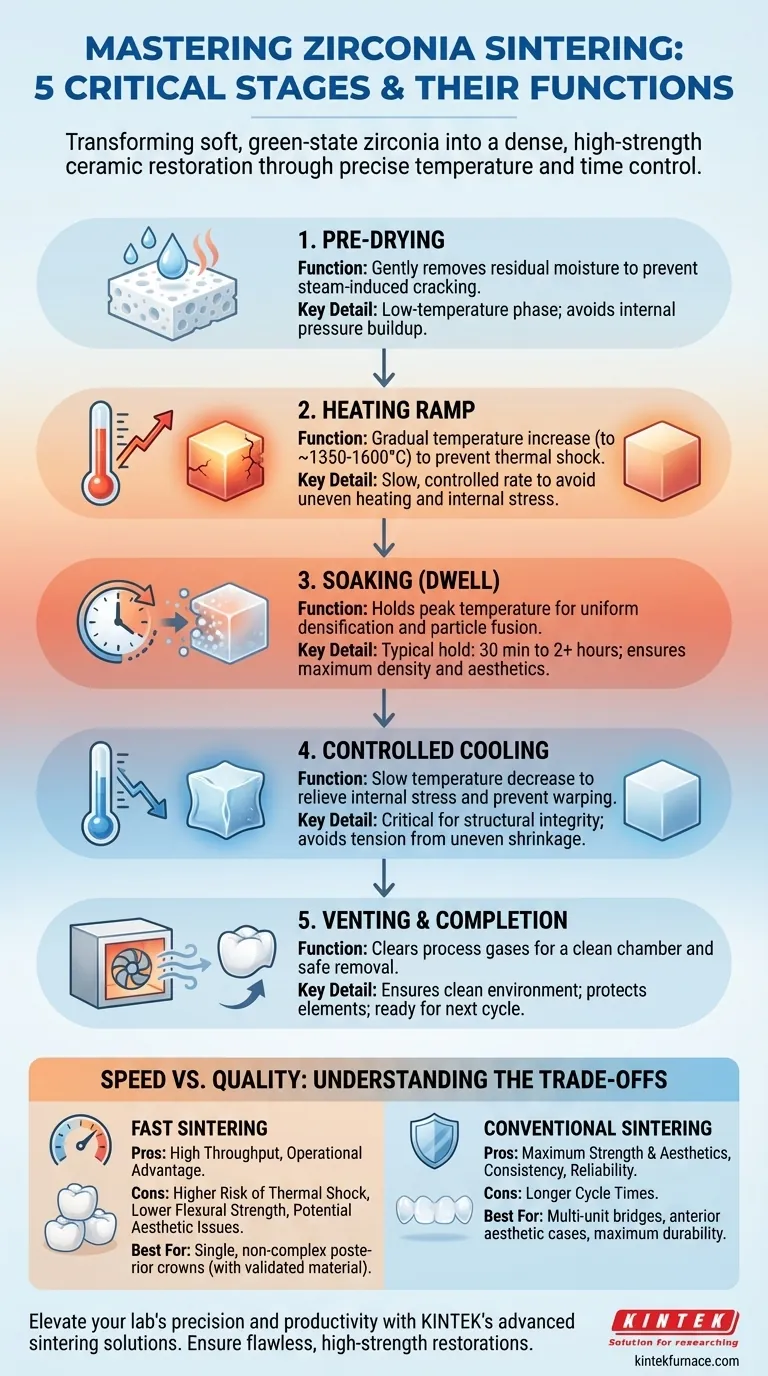

In essence, a zirconia sintering program consists of five critical stages: pre-drying, heating, soaking, cooling, and venting. Each stage carefully manipulates temperature and time to transform the soft, milled "green state" zirconia into a dense, high-strength final ceramic restoration without introducing internal stresses or defects.

The goal of a sintering program is not simply to heat the zirconia. It is to precisely manage a complex material transformation, where every stage is designed to prevent specific failures—from cracking and warping to poor aesthetics—ensuring a predictable and durable final product.

The Transformation: From Chalk to Ceramic

Sintering is the process that gives zirconia its final strength and density. Before sintering, a milled restoration is porous, weak, and oversized. The furnace program guides this material through a controlled shrinkage and densification process. Understanding each step is key to mastering the outcome.

Stage 1: Pre-Drying

This initial, low-temperature phase is designed to gently remove any residual moisture from the zirconia restoration or the furnace chamber.

Skipping this or rushing it is a common mistake. If moisture is trapped and the temperature rises too quickly, the water turns to steam, creating immense internal pressure that can cause micro-fractures or even visible cracks in the final restoration.

Stage 2: The Heating Ramp

Once dry, the furnace begins to gradually increase the temperature towards its peak. This is known as the heating ramp.

The rate of temperature increase is critical. A slow, controlled ramp prevents thermal shock, where different parts of the restoration heat up at different rates, creating internal stress. The target temperature typically falls between 1350°C and 1600°C, depending on the specific type of zirconia being used.

Stage 3: Soaking (or Dwell)

The furnace holds the restoration at the peak temperature for a specified period, typically from 30 minutes to over two hours. This "soaking" phase is where the most critical part of sintering occurs.

This hold time allows the temperature to distribute completely and uniformly throughout the entire restoration, even in the thickest areas. It ensures that all particles fuse together, eliminating porosity and allowing the material to achieve its maximum density and specified translucency.

Stage 4: Controlled Cooling

Arguably the most critical stage for preventing failure, cooling must be as carefully controlled as heating. The furnace temperature is lowered slowly and deliberately.

Rapid cooling is the primary cause of cracked or warped restorations. As the outside of the zirconia cools and shrinks faster than the inside, it creates immense tension. A slow cooling phase allows the entire restoration to shrink uniformly, relieving these internal stresses and ensuring its structural integrity.

Stage 5: Venting and Completion

In the final stage, the furnace program may actively vent the chamber to clear away any process gases before allowing the door to be opened. This ensures a clean environment for the next cycle and protects the heating elements.

Only after the furnace has cooled to a safe temperature can the final, fully sintered restoration be removed. It will now be significantly smaller, denser, and possess its final high-strength properties.

Understanding the Trade-offs: Speed vs. Quality

Modern furnaces often advertise "fast sintering" cycles, some completing in as little as an hour. While tempting for high-production labs, this speed comes with significant compromises.

The Allure of Fast Sintering

The obvious benefit is increased throughput. A lab can process more cases in a single day, which is a major operational advantage. These cycles are enabled by advanced heating elements and precise PID temperature controllers that can ramp temperatures up and down very quickly.

The Hidden Risks of Speed

Fast cycles dramatically increase the risk of thermal shock during both heating and cooling. This can lead to lower flexural strength, reduced longevity, and a higher chance of catastrophic failure down the line. Furthermore, rushed soaking times may result in incomplete sintering, affecting the material's aesthetic properties like translucency.

When to Choose Fast vs. Conventional Cycles

Fast sintering should not be the default. It is best reserved for specific situations, such as single, non-complex posterior crowns, using a zirconia material explicitly validated by its manufacturer for that exact fast cycle. For multi-unit bridges, anterior aesthetic cases, or when maximum durability is required, a slower, conventional sintering program remains the gold standard.

Making the Right Choice for Your Goal

Your choice of sintering program should always be driven by the clinical or production goal.

- If your primary focus is maximum strength and aesthetics: Always default to a conventional, slower sintering cycle. Never rush the cooling stage, especially for large or complex restorations like bridges.

- If your primary focus is high throughput for simple cases: You may use a fast sintering cycle, but only with a zirconia material that has been specifically tested and approved for that exact program by the manufacturer.

- If your primary focus is consistency and reliability: Invest in a furnace with high-purity heating elements and precise PID temperature control. These features are not luxuries; they are fundamental to executing these sensitive programs correctly every time.

Ultimately, mastering the sintering process is about controlling variables to achieve a predictable, high-quality outcome for every case.

Summary Table:

| Stage | Function | Key Details |

|---|---|---|

| Pre-Drying | Removes moisture to prevent cracking | Low temperature, avoids steam-induced fractures |

| Heating Ramp | Gradual temperature increase to prevent thermal shock | Controlled rate, targets 1350°C–1600°C |

| Soaking (Dwell) | Holds peak temperature for densification | 30 min–2+ hours, ensures uniform particle fusion |

| Controlled Cooling | Slow temperature decrease to prevent warping | Avoids internal stress, critical for structural integrity |

| Venting | Clears process gases for a clean chamber | Protects elements, prepares for next cycle |

Elevate your lab's precision and productivity with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored for zirconia sintering. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is enhanced by deep customization to meet your unique experimental needs. Ensure flawless, high-strength dental restorations every time—contact us today to discuss how we can optimize your sintering processes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time