Yes, a furnace designed for both processes can be used for zirconia, but it is critical to understand the distinction. While modern "combi" furnaces are built to handle both porcelain firing and zirconia sintering, a standard or older porcelain-only furnace lacks the required temperature capabilities and programming for successful zirconia processing. The two procedures are fundamentally different, and using the wrong equipment or cycle will compromise the final restoration.

The core issue is not whether a single box can get hot, but whether it can precisely execute two vastly different thermal processes. Porcelain firing is a relatively low-temperature, short-duration process for aesthetics, while zirconia sintering is a high-temperature, long-duration process essential for structural integrity.

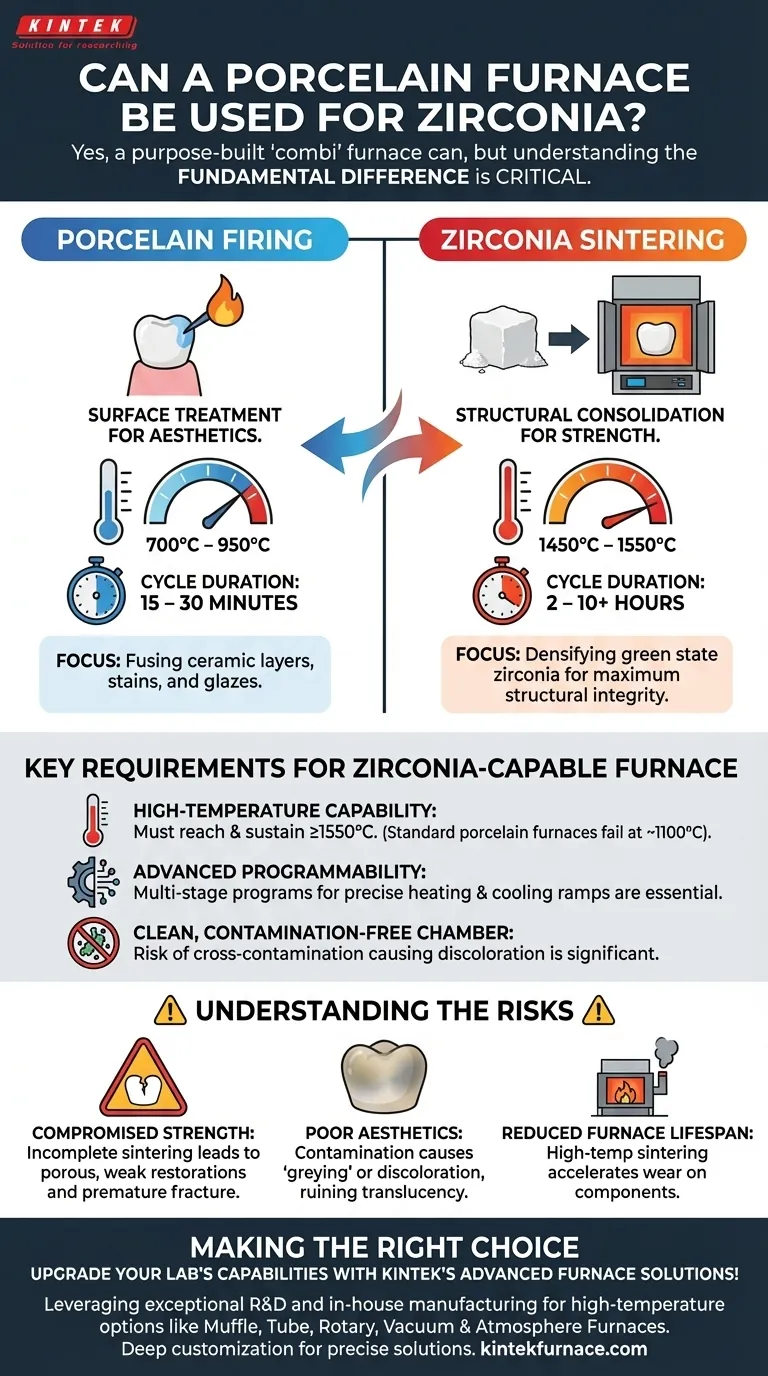

The Fundamental Difference: Firing vs. Sintering

To understand the equipment requirements, you must first understand the two distinct material science processes at play. They are not interchangeable.

What is Porcelain Firing?

Porcelain firing is primarily a surface treatment. It involves heating a restoration to fuse layers of dental ceramic, apply stains, or create a final glaze.

This process typically occurs at temperatures between 700°C and 950°C. The cycles are short, often lasting only 15-30 minutes, and focus on achieving the correct surface texture and shade.

What is Zirconia Sintering?

Sintering is a transformative process that gives zirconia its strength. It takes a pre-milled, chalk-like "green state" or "white state" restoration and consolidates it into a dense, hard final form.

This requires much higher temperatures, typically between 1450°C and 1550°C, held for an extended period. A full sintering cycle is a multi-stage program that can last anywhere from 2 to over 10 hours, including precisely controlled heating and cooling ramps.

Why This Distinction is Critical

The massive difference in peak temperature and cycle duration is the central challenge. A furnace must be specifically engineered to safely reach and hold 1550°C for hours without damaging its own components, like the heating elements or insulation.

Furthermore, the slow, controlled cool-down phase in a sintering cycle is crucial for preventing thermal shock and micro-fractures in the zirconia, ensuring its maximum strength.

Key Requirements for a Zirconia-Capable Furnace

Before attempting to sinter zirconia, you must confirm your furnace meets several non-negotiable criteria.

High-Temperature Capability

The furnace must be officially rated by the manufacturer to reach and sustain temperatures of at least 1550°C. A standard porcelain furnace, which may max out around 1100°C-1200°C, simply cannot perform the sintering process.

Advanced Programmability

A zirconia-capable furnace must allow for creating and saving complex, multi-stage programs. You need precise control over the heating rate (how fast the temperature rises), the hold time at peak temperature, and the cooling rate. Simple, pre-set porcelain programs are inadequate.

A Clean, Contamination-Free Chamber

Using the same furnace for both processes introduces a significant risk of cross-contamination. Residues from glazing or porcelain firing can become airborne at high sintering temperatures and embed into the zirconia surface, causing discoloration and compromising the aesthetic outcome.

Understanding the Trade-offs and Risks

Using an inadequate furnace or a contaminated combi-furnace carries significant risks that directly impact clinical success.

Compromised Structural Integrity

Incomplete sintering due to incorrect temperatures or short cycles results in a porous, weak restoration. This material will not have the manufacturer-stated flexural strength and is at a high risk of premature fracture in the patient's mouth.

Poor Aesthetic Results

Contamination from other materials is a leading cause of "greying" or discoloration of zirconia restorations. This completely negates the aesthetic benefits of using modern, translucent zirconia materials.

Reduced Furnace Lifespan

Consistently running long, high-temperature sintering cycles in a furnace not explicitly designed for this workload will cause accelerated wear on the heating elements, thermocouple, and insulation. This leads to more frequent, costly repairs and inaccurate temperature readings.

Making the Right Choice for Your Goal

Your decision should be based on your lab's production volume, quality standards, and budget.

- If your primary focus is high-quality, consistent zirconia restorations: Invest in a dedicated sintering furnace. This eliminates contamination risks and ensures every unit is processed according to ideal parameters.

- If you run a versatile lab with mixed production: A modern "combi" furnace is a viable solution, but you must enforce a strict protocol of using separate, dedicated firing trays and cleaning the chamber meticulously between material types.

- If you are considering a new furnace purchase: Prioritize a model that is explicitly marketed as a combination furnace with separate, validated programs for both porcelain and the specific types of zirconia you plan to use.

Understanding the distinct requirements of each material is the key to achieving predictable, high-quality results with your equipment.

Summary Table:

| Aspect | Porcelain Firing | Zirconia Sintering |

|---|---|---|

| Process Type | Surface treatment for aesthetics | Structural consolidation for strength |

| Temperature Range | 700°C - 950°C | 1450°C - 1550°C |

| Cycle Duration | 15-30 minutes | 2-10+ hours |

| Key Risks | Inadequate for zirconia | Compromised strength, discoloration if improper furnace used |

Upgrade your lab's capabilities with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, whether you're sintering zirconia or firing porcelain. Contact us today to enhance your efficiency and achieve superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow