At its core, the significance of biocompatibility in dental ceramics is about patient safety and long-term oral health. The high-temperature firing process within a porcelain furnace is the critical step that transforms raw ceramic powders into a stable, non-toxic, and inert final restoration that will not harm the patient's surrounding tissues, even after years of use in the demanding environment of the oral cavity.

The central challenge with any dental restoration is that it is a foreign material placed into a sensitive biological system. The porcelain furnace solves this by using controlled, high-heat processing to lock the ceramic's chemical components into a solid, inert glass-like or crystalline structure, ensuring it is non-reactive and safe for the patient.

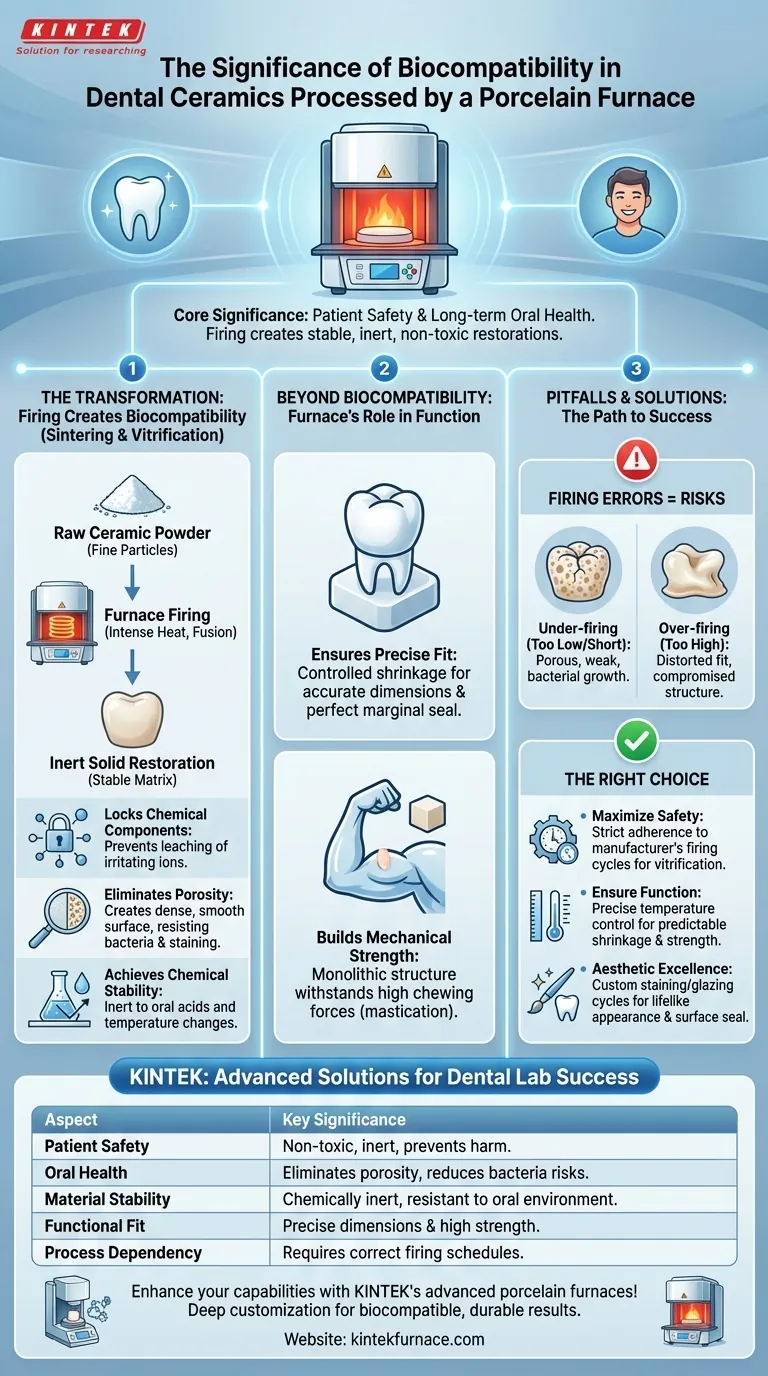

The Transformation: How Firing Creates a Biocompatible Material

The journey from a simple ceramic powder to a biocompatible restoration is a marvel of material science, orchestrated entirely within the porcelain furnace. This process, known as sintering, is what guarantees the material's safety and stability.

From Loose Powder to an Inert Solid

The raw materials for dental ceramics exist as fine particles. In this state, they are not suitable for intraoral use.

The intense heat inside the furnace causes these particles to fuse together, a process called vitrification. This locks all chemical components into a stable, solid matrix.

This transformation is what prevents potentially irritating ions or substances from leaching out into the patient's saliva over time.

Eliminating Porosity for Health

An unfired or under-fired ceramic is porous, like a sponge. These microscopic voids can harbor bacteria, leading to inflammation, plaque accumulation, and potential secondary decay.

The firing process eliminates this porosity, creating a dense, smooth surface. This polished surface is highly resistant to bacterial colonization and staining, which directly supports the health of the surrounding gum tissue.

Achieving Chemical Stability

The oral cavity is a harsh environment, subject to constant changes in temperature and pH from foods and drinks.

A properly fired ceramic is chemically inert and highly resistant to corrosion or degradation from these acids. This stability ensures the restoration does not break down and release unwanted byproducts into the body.

Beyond Biocompatibility: The Furnace's Role in Function

While safety is the primary concern, the firing process is also essential for the functional success of the restoration. A restoration that doesn't function correctly is, by definition, not biocompatible in a practical sense.

Ensuring a Precise Fit

During firing, the ceramic undergoes controlled and predictable shrinkage. Dental technicians account for this shrinkage to create a restoration with exceptionally accurate dimensions.

This precision is critical for a perfect fit. A poorly fitting crown or veneer can create gaps that trap food, irritate the gums, or cause issues with the patient's bite.

Building Mechanical Strength

The fusion of ceramic particles during firing creates a monolithic structure with immense strength.

This strength is necessary to withstand the powerful forces of chewing (mastication). An improperly fired, weak restoration is prone to fracture, which can create sharp edges that damage soft tissue and require a complete replacement.

Understanding the Pitfalls: When Firing Goes Wrong

Achieving biocompatibility is entirely dependent on the correct execution of the firing process. Errors can compromise the safety and integrity of the final product.

The Dangers of Improper Firing Schedules

If the furnace temperature is too low or the time is too short (under-firing), the ceramic will be porous and weak. This can lead to bacterial colonization and the potential leaching of components.

If the temperature is too high (over-firing), the ceramic can slump or distort, ruining the precise fit required for good oral health. This also compromises its internal structure and strength.

The Material Itself Matters

The porcelain furnace perfects the material, but it cannot make an inherently unsafe material biocompatible.

The process relies on starting with high-purity, medical-grade ceramic materials, such as zirconia or lithium disilicate, which are known for their excellent biocompatibility. The furnace's role is to realize that inherent potential.

Making the Right Choice for Your Goal

The application of this knowledge depends on your specific role and objective, whether in a dental lab or a clinical setting.

- If your primary focus is maximizing patient safety: Adhere strictly to the ceramic manufacturer's recommended firing cycles to guarantee complete vitrification and create a chemically inert surface.

- If your primary focus is ensuring long-term functional success: Prioritize precise temperature control and cooling rates to achieve predictable shrinkage, ensuring a perfect fit and maximum mechanical strength.

- If your primary focus is aesthetic excellence: Use custom staining and glazing cycles as the final step to create a lifelike appearance while sealing the surface for enhanced biocompatibility and stain resistance.

Ultimately, the porcelain furnace is the critical bridge between advanced material science and a successful, long-lasting clinical outcome for the patient.

Summary Table:

| Aspect | Key Significance |

|---|---|

| Patient Safety | Creates non-toxic, inert materials that prevent tissue harm and leaching of ions. |

| Oral Health | Eliminates porosity to reduce bacterial colonization and inflammation risks. |

| Material Stability | Ensures chemical inertness and resistance to oral environment stresses. |

| Functional Fit | Achieves precise dimensions and strength for comfortable, long-lasting restorations. |

| Process Dependency | Relies on correct firing schedules to avoid under-firing or over-firing issues. |

Enhance your dental lab's capabilities with KINTEK's advanced porcelain furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering biocompatible, durable dental ceramics for superior patient outcomes. Contact us today to discuss how our solutions can optimize your processes and elevate your results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity