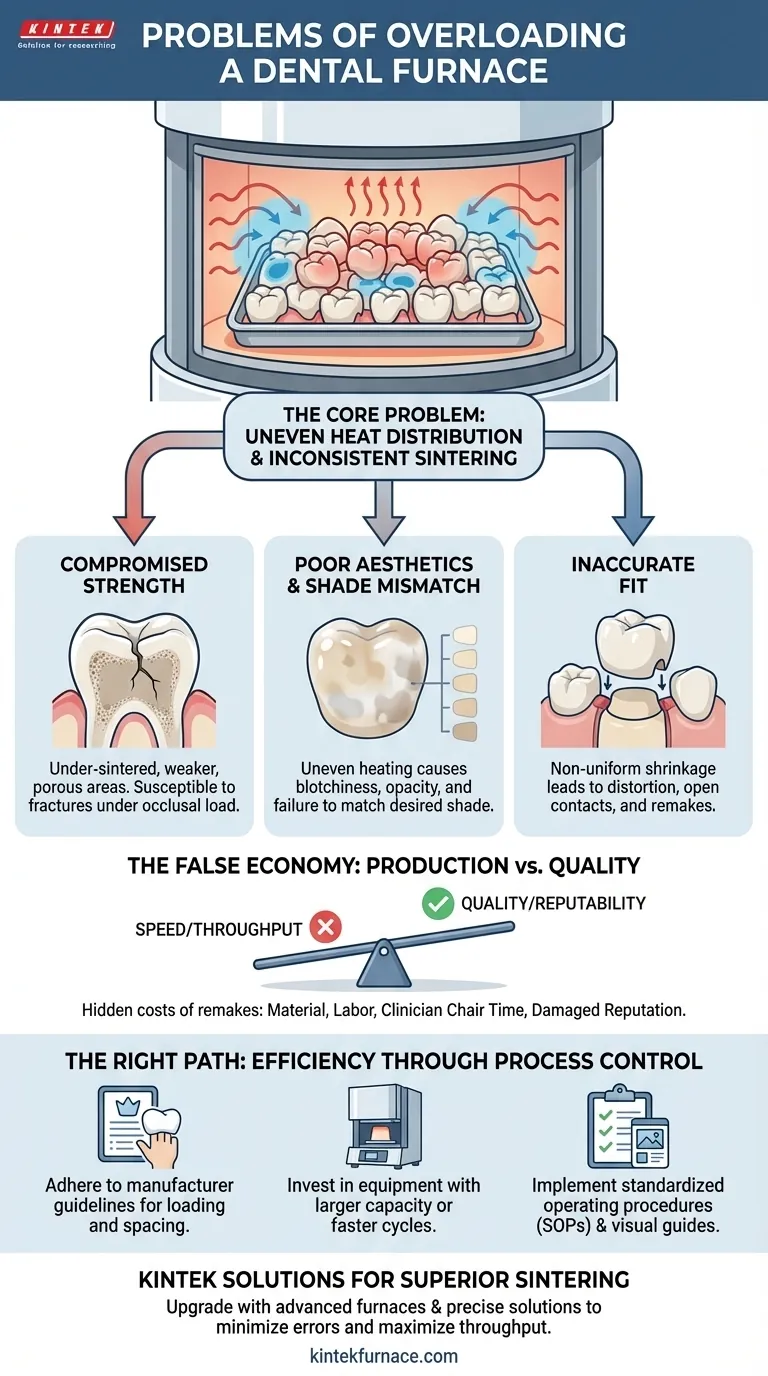

At its core, overloading a dental furnace causes uneven heating and inconsistent sintering of the restorations inside. This fundamental process failure directly compromises the physical and aesthetic quality of the final crowns, bridges, or other prosthetics, leading to costly remakes and unpredictable results.

The temptation to increase throughput by overloading a furnace is a false economy. The minor time saved is consistently outweighed by the significant cost and clinical failures caused by compromised restorations.

The Core Problem: Uneven Heat Distribution

A dental furnace is engineered to create a perfectly uniform thermal environment. Overloading disrupts this critical function, leading to a cascade of problems that begin with inconsistent heating.

Obstructed Heat Flow

When restorations are packed too closely together, they create physical barriers. These obstructions prevent radiant heat from the furnace's elements from reaching every surface of every unit uniformly.

Creating Hot and Cold Spots

This obstruction results in a significant temperature gradient across the sintering tray. Units on the outer edges receive more direct heat and get hotter faster, while units clustered in the center remain cooler for longer.

The Impact on Sintering

Sintering is the process where ceramic particles fuse together under precise heat and time. When the temperature is not uniform, the sintering process itself becomes inconsistent, resulting in a restoration with different properties in different areas.

Consequences for the Final Restoration

An unevenly sintered restoration is a failed restoration. The consequences manifest as tangible defects that undermine its clinical function and aesthetic value.

Compromised Strength

Under-sintered areas within the ceramic (often zirconia) will not reach their target density. These regions are significantly weaker and more porous, making the final crown highly susceptible to fractures under normal occlusal load.

Poor Aesthetics and Shade Mismatch

The final shade, value, and translucency of modern ceramics are directly linked to a precise sintering cycle. Uneven heating can lead to restorations that are blotchy, opaque in some areas, and overly translucent in others, failing to match the desired shade.

Inaccurate Fit

All-ceramic restorations are designed to shrink by a predictable percentage during sintering. If one part of a crown is heated differently than another, the shrinkage will be non-uniform, leading to distortion. This results in a poor marginal fit, open contacts, or a restoration that simply won't seat.

Understanding the Trade-offs: Production vs. Quality

The primary motivation for overloading is a desire to increase production capacity without investing in new equipment. However, this approach is fundamentally flawed and introduces unacceptable risks.

The Hidden Costs of Remakes

A single failed restoration requires new material, additional technician labor to re-fabricate it, and valuable clinician chair time for a second delivery appointment. These costs far exceed the perceived savings of running one fewer furnace cycle.

The Risk to Reputation

Consistently delivering ill-fitting or weak restorations damages the reputation of the dental lab and the trust of the clinicians it serves. The long-term business cost of unreliability is immense.

The Correct Path to Higher Throughput

True efficiency comes from process control, not shortcuts. To increase output, a lab must accurately analyze its workload and invest in equipment that matches its needs, whether that means a furnace with a larger chamber, a faster cycle, or simply running more correctly loaded cycles.

Making the Right Choice for Your Goal

To avoid these issues, your operational protocols must prioritize quality and predictability over perceived speed.

- If your primary focus is clinical excellence: Always adhere strictly to the manufacturer's guidelines for the number of units and the spacing between them for every cycle.

- If your primary focus is increasing output: Invest in analyzing your daily and weekly production needs to determine if you need a furnace with a larger capacity or faster sintering cycles to meet demand without compromising quality.

- If your primary focus is minimizing errors: Implement standardized operating procedures (SOPs) for furnace loading and create visual guides near the equipment to ensure every technician loads the furnace correctly, every time.

Ultimately, mastering the sintering process by ensuring proper furnace loading is fundamental to achieving predictable, high-quality results in modern dentistry.

Summary Table:

| Problem | Consequence | Prevention |

|---|---|---|

| Uneven heat distribution | Inconsistent sintering, weak strength | Follow manufacturer loading guidelines |

| Hot and cold spots | Shade mismatch, poor aesthetics | Use proper spacing between units |

| Non-uniform shrinkage | Ill-fitting restorations, remakes | Implement SOPs for loading |

Upgrade your dental lab's efficiency and quality with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, minimizing errors and maximizing throughput. Contact us today to discuss how our products can enhance your sintering process and deliver superior restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations