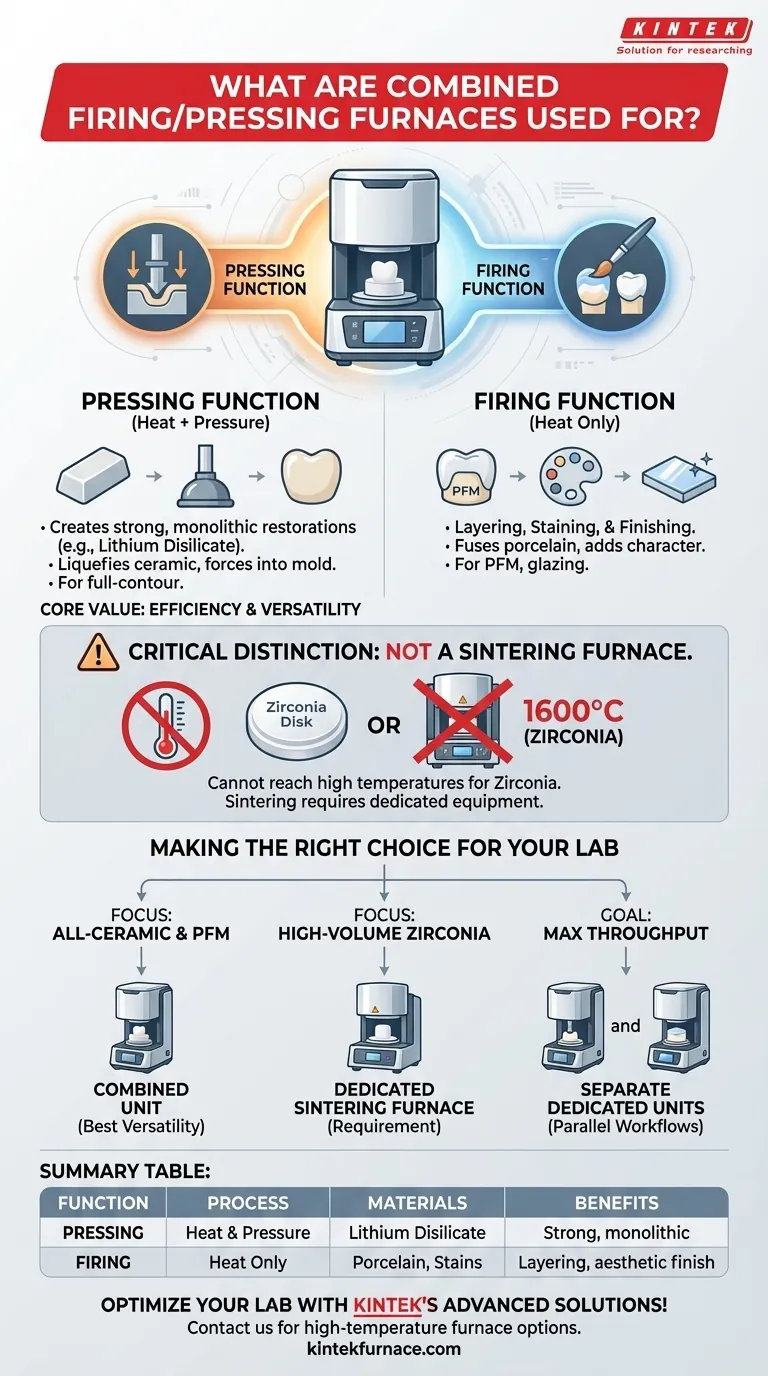

In modern dental laboratories, a combined firing and pressing furnace is a versatile device that merges two critical functions into a single unit. It is used to fabricate pressed-ceramic restorations like crowns and veneers, and it is also used for the conventional firing process required for layering porcelain, staining, and glazing.

The core value of a combined furnace is its efficiency, integrating the capability to both press monolithic ceramic restorations and fire layered porcelain restorations within one machine. This makes it a foundational piece of equipment, distinct from highly specialized units like sintering furnaces, which serve a completely different purpose.

The Two Core Functions Explained

A combined furnace is not performing one new type of process, but rather two separate, established processes. Understanding each function is key to understanding the furnace's role in the lab.

The Pressing Function: Creating Full-Contour Restorations

The "pressing" function uses a combination of precise heat and pressure. This process is used to create strong, monolithic restorations from pressable ceramic materials.

The procedure involves liquefying a specialized ceramic ingot or block inside the furnace. Once molten, a plunger applies pressure, forcing the liquid ceramic into a hollow mold created using a lost-wax technique. This is the standard method for fabricating restorations from materials like lithium disilicate.

The Firing Function: Layering and Finishing

The "firing" function is essentially the capability of a traditional porcelain furnace. It is used for any process that requires heating dental ceramics to achieve fusion, maturation, or glazing without the use of pressure.

This includes firing porcelain layers onto a metal framework for a Porcelain-Fused-to-Metal (PFM) crown, adding stains to characterize a restoration, or applying a final glaze to create a smooth, life-like surface. This process relies on precise temperature control to prevent cracking and ensure a strong bond.

How It Differs from Other Dental Furnaces

The term "furnace" is used for several different machines in a dental lab, each designed for a specific material and process. A combined firing/pressing furnace is often confused with a sintering furnace, but their functions are fundamentally different.

Firing/Pressing vs. Sintering Furnaces

The most critical distinction is between a combined furnace and a sintering furnace. A sintering furnace is designed for one purpose: to process zirconia restorations after they have been milled.

Sintering involves heating zirconia to extremely high temperatures—often up to 1600°C—to shrink the material, eliminate porosity, and transform it into its final, dense, and durable state.

A combined firing/pressing furnace cannot reach these temperatures and is not designed for the sintering process. Its heating elements are engineered for the lower temperatures required by pressable ceramics and conventional porcelains.

Understanding the Trade-offs

While highly versatile, a combined furnace is not a universal solution. Understanding its limitations is crucial for making smart equipment decisions.

The Primary Limitation: It Cannot Sinter Zirconia

The most common mistake is assuming a combined furnace can handle all ceramic materials. It is critical to remember that zirconia requires a dedicated sintering furnace. Attempting to process zirconia in a combined furnace will not work and may damage the equipment.

Versatility vs. High-Volume Workflow

For most labs, a combined unit is ideal because it saves space and reduces initial investment. However, a very high-volume lab might prefer separate, dedicated units.

Having a dedicated pressing furnace and several dedicated firing/glazing furnaces can prevent bottlenecks. This allows technicians to press new cases while others are simultaneously glazing finished work, optimizing throughput.

Making the Right Choice for Your Lab

Selecting the right furnace depends entirely on the types of restorations your laboratory produces.

- If your primary focus is all-ceramic restorations (like e.max) and traditional PFM work: A combined firing/pressing furnace offers the best combination of versatility and efficiency for your core business.

- If your primary focus is high-volume zirconia crowns and bridges: A dedicated sintering furnace is an absolute requirement, as a combined furnace cannot perform this high-temperature process.

- If your goal is to maximize throughput for all restoration types: Your lab may benefit from having both a dedicated sintering furnace and separate pressing and firing furnaces to run multiple workflows in parallel.

Ultimately, understanding that these furnaces are specialized tools for different materials and processes is the key to equipping your lab for success.

Summary Table:

| Function | Process | Materials Used | Key Benefits |

|---|---|---|---|

| Pressing | Applies heat and pressure to mold ceramics | Lithium disilicate, pressable ceramics | Creates strong, monolithic restorations like crowns and veneers |

| Firing | Heats ceramics for fusion and glazing | Porcelain, stains, glazes | Enables layering, staining, and finishing for PFM and aesthetic restorations |

Optimize your dental lab with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether you're handling pressed ceramics or traditional porcelain work. Contact us today to discuss how our furnaces can enhance your efficiency and quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow