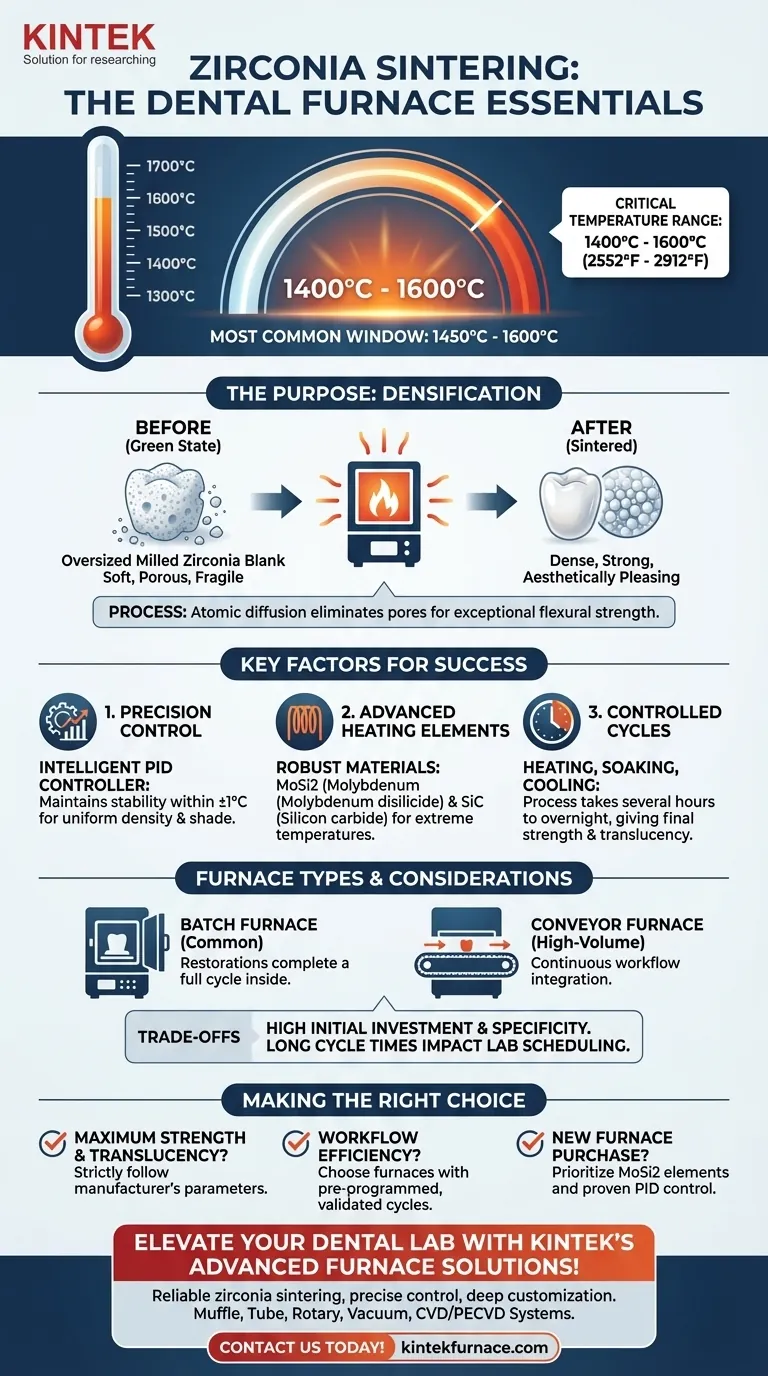

To effectively sinter zirconia, a dental furnace must reach a temperature range between 1400°C and 1600°C (2552°F and 2912°F). The most common operational window is between 1450°C and 1600°C. This extreme heat is necessary to transform the soft, milled zirconia block into a dense, strong, and aesthetically pleasing final restoration.

The specific temperature is only one part of the equation. Achieving a successful clinical outcome depends on a precisely controlled heating and cooling cycle, as this process is what gives the final zirconia restoration its required strength and translucency.

The Purpose of High-Temperature Sintering

Sintering is the critical step that transforms a chalky, fragile zirconia milling blank into a final, high-strength ceramic. Understanding this process reveals why precise temperature management is non-negotiable.

From Milled Blank to Final Crown

After a crown or bridge is designed and milled, the material is in a "green" or pre-sintered state. It is soft, porous, and oversized to account for shrinkage. The sintering furnace applies controlled heat to cause the zirconia particles to bond and densify, shrinking the restoration to its final, exact dimensions.

Why This Specific Temperature Range?

The 1400°C to 1600°C range is required to initiate the atomic diffusion that eliminates pores between zirconia particles. This process, known as densification, is what gives the material its exceptional flexural strength. Temperatures below this range will result in an under-sintered, weak restoration, while excessive temperatures can lead to unwanted grain growth, reducing translucency.

The Critical Role of Precision Control

Modern zirconia furnaces use intelligent PID (Proportional-Integral-Derivative) controllers to maintain temperature stability, often within ±1°C. This level of precision is not a luxury; it is essential for consistency. It ensures that every part of the restoration receives the exact same thermal treatment, guaranteeing uniform density, hardness, and shade.

Key Furnace Components and Capabilities

The ability to reliably reach and maintain these extreme temperatures depends on specialized furnace technology. Not all dental furnaces are capable of sintering zirconia.

Advanced Heating Elements

Standard furnaces cannot withstand the thermal stress of zirconia sintering. Zirconia furnaces are equipped with robust heating elements made from materials like silicon carbide (SiC) or, more commonly, molybdenum disilicide (MoSi2). These high-performance elements are designed for long life at extreme temperatures.

Batch vs. Continuous Processing

Most dental labs and practices use batch furnaces, where restorations are placed inside for a complete heating and cooling cycle. For high-volume production labs, conveyor furnaces exist that allow for a continuous workflow, integrating the sintering process directly with milling and pressing stations.

Understanding the Trade-offs and Considerations

While essential for modern restorative dentistry, zirconia sintering comes with operational realities that every professional must manage.

Sintering Cycles Are Not Instantaneous

The entire sintering cycle, including the controlled ramp-up, the "soak" at peak temperature, and the slow cool-down, can take several hours to overnight. This cycle time is a significant factor in lab scheduling and the ability to offer same-day restorations.

High Initial Investment and Specificity

Zirconia-capable furnaces represent a higher upfront cost compared to standard ceramic ovens. Furthermore, they are highly specialized. A practice focused solely on other types of ceramics may find the investment and longer cycle times unsuitable for their business model.

Making the Right Choice for Your Goal

Your approach to sintering should align with your clinical or business objectives. Use these principles as a guide.

- If your primary focus is achieving maximum strength and translucency: Strictly follow the specific sintering parameters provided by the zirconia manufacturer, paying close attention to peak temperature and cycle duration.

- If your primary focus is workflow efficiency: Invest in a furnace with pre-programmed, validated cycles for different zirconia types, which can help balance speed with quality for standard restorations.

- If you are purchasing a new furnace: Prioritize models with high-performance MoSi2 heating elements and proven PID temperature control to ensure reliability and future-proof your investment for new zirconia materials.

Mastering the principles of sintering is fundamental to producing predictable, durable, and beautiful zirconia restorations.

Summary Table:

| Aspect | Details |

|---|---|

| Temperature Range | 1400°C to 1600°C (1450°C to 1600°C common) |

| Purpose | Densifies zirconia for strength and translucency |

| Key Factors | Precise control (±1°C), heating/cooling cycles, material-specific parameters |

| Furnace Types | Batch furnaces (common), conveyor furnaces (high-volume) |

| Heating Elements | Molybdenum disilicide (MoSi2), silicon carbide (SiC) |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable sintering furnaces tailored for zirconia and other materials. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by deep customization to meet your unique experimental needs. Ensure precise temperature control, uniform heating, and durable performance for consistent, high-quality dental restorations. Contact us today to discuss how we can optimize your sintering processes and boost efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time