To ensure consistent performance and longevity, the most common maintenance tasks for a zirconia sintering furnace are routine cleaning of the furnace chamber, regular inspection of the heating elements, and periodic calibration of the temperature control system. These actions are fundamental to preventing contamination and maintaining the thermal accuracy required for producing high-quality, predictable zirconia restorations.

Furnace maintenance is not just about preventing breakdowns; it is about guaranteeing the precision and purity of the sintering environment. Inconsistent maintenance directly leads to inconsistent material properties, affecting the strength, fit, and aesthetics of your final restorations.

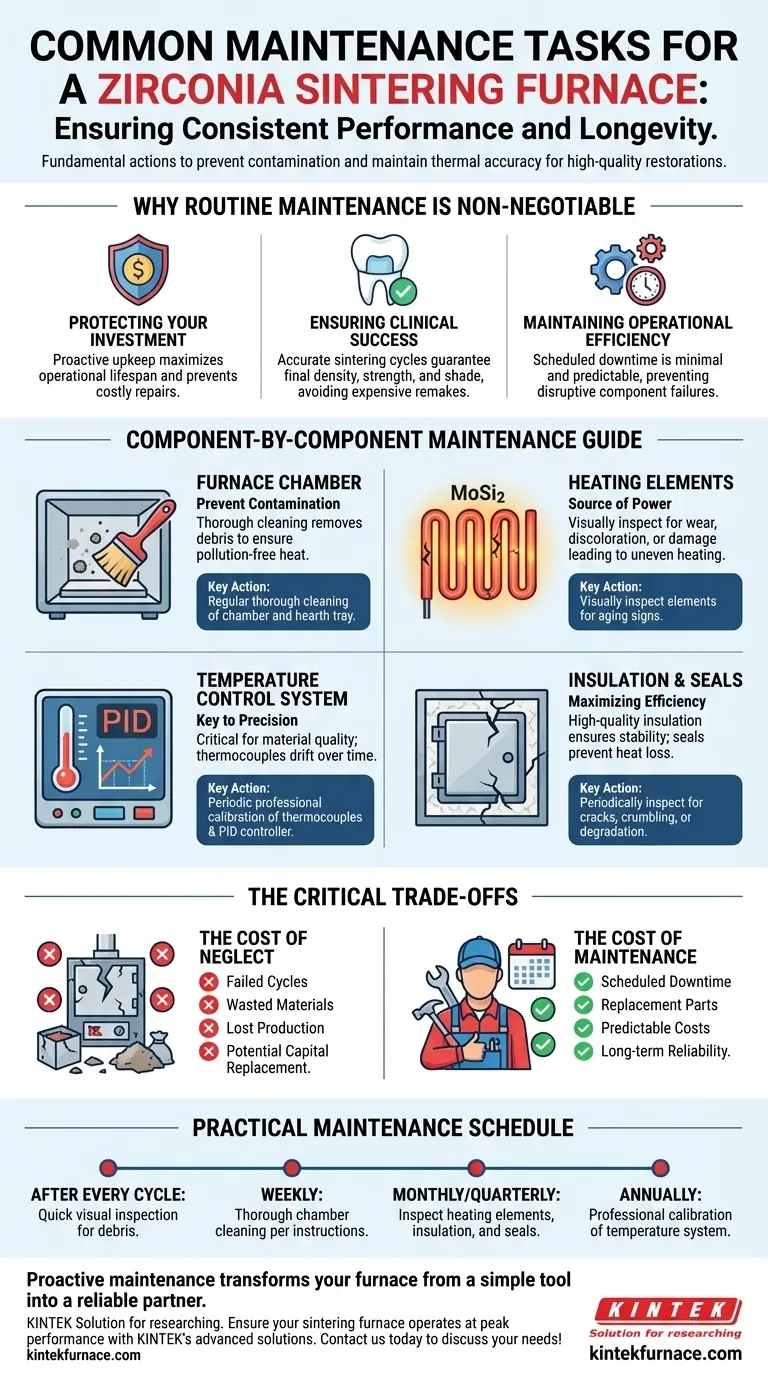

Why Routine Maintenance is Non-Negotiable

A zirconia furnace is a precision instrument. Neglecting its upkeep compromises the very reason you invested in it: to produce strong, aesthetic, and perfectly fitting biocompatible materials with repeatable accuracy.

Protecting Your Investment

A sintering furnace is a significant capital expense. Proactive maintenance protects this asset from premature failure, catastrophic damage, and costly emergency repairs, maximizing its operational lifespan.

Ensuring Clinical Success

The final density, strength, and shade of a zirconia restoration are directly tied to the accuracy of the sintering cycle. A poorly maintained furnace can lead to weak or discolored crowns, requiring expensive and time-consuming remakes.

Maintaining Operational Efficiency

Scheduled downtime for maintenance is predictable and minimal. Unscheduled downtime due to component failure is disruptive and costly, halting production and delaying cases. Regular upkeep prevents these sudden interruptions.

A Component-by-Component Maintenance Guide

Effective maintenance focuses on the key systems responsible for creating a pure, precisely controlled thermal environment. Always consult your manufacturer’s manual for specific instructions and schedules.

The Furnace Chamber: Preventing Contamination

The interior of the furnace must remain pristine. Contaminants can vaporize at high temperatures and embed into the zirconia, causing discoloration and compromising biocompatibility.

Perform a thorough cleaning of the chamber and hearth tray regularly. This removes any dust or ceramic debris, ensuring that high-purity heating elements can provide clean, pollution-free heat.

Heating Elements: The Source of Power

The heating elements, typically made of molybdenum disilicide (MoSi2) or silicon carbide (SiC), do the heavy lifting. Over time, they can degrade, crack, or age, leading to uneven heating.

Visually inspect the elements for any signs of wear, discoloration, or physical damage. An aging element that heats unevenly is a primary cause of inconsistent sintering results and should be replaced before it fails completely.

Temperature Control System: The Key to Precision

This is the most critical system for material quality. The furnace relies on thermocouples to measure temperature and a PID controller to regulate it, often maintaining an accuracy of ±1℃.

Thermocouples can drift over time, reporting incorrect temperatures. This seemingly small error can ruin an entire batch of restorations. Regular calibration by a qualified technician is essential to guarantee that the temperature on the screen matches the actual temperature in the chamber.

Insulation and Seals: Maximizing Efficiency

High-quality insulation ensures thermal stability and energy efficiency. Door seals prevent heat from escaping and air from entering the chamber during the cycle.

Periodically inspect the insulation for cracks or crumbling. Check the door seal for any signs of degradation or damage that could compromise the integrity of the sintering atmosphere.

Understanding the Critical Trade-offs

Making informed decisions about maintenance requires weighing the costs of action against the risks of inaction.

The Cost of Neglect vs. The Cost of Maintenance

The "cost" of maintenance is a few hours of scheduled downtime and the price of replacement parts. The cost of neglect includes failed sintering cycles, wasted materials, lost production time, and the potential for a complete furnace failure requiring a major capital replacement.

Following vs. Ignoring Manufacturer Guidelines

The manufacturer's manual is your definitive guide. It provides maintenance schedules and procedures tested specifically for your model. Ignoring these guidelines not only risks damaging the equipment but can also void your warranty.

Safety During Maintenance

Always prioritize safety. Before performing any internal maintenance, ensure the furnace is completely powered off and has cooled to room temperature. Wear appropriate personal protective equipment (PPE), such as heat-resistant gloves and safety glasses, and ensure the area is well-ventilated.

A Practical Maintenance Schedule

While your manufacturer's manual is the final authority, a typical maintenance schedule can be broken down by frequency.

- After every cycle: Perform a quick visual inspection of the chamber and hearth plate for any obvious debris or residue.

- Weekly: Conduct a more thorough cleaning of the furnace chamber according to your manufacturer's instructions.

- Monthly or Quarterly: Visually inspect the heating elements for signs of aging or damage, and check the condition of the insulation and door seal.

- Annually or as specified: Schedule a professional service for calibration of the temperature control system and thermocouples.

Proactive maintenance transforms your furnace from a simple tool into a reliable partner in producing exceptional results.

Summary Table:

| Maintenance Task | Frequency | Key Actions |

|---|---|---|

| Chamber Cleaning | Weekly | Remove dust and debris to prevent contamination |

| Heating Element Inspection | Monthly/Quarterly | Check for wear, discoloration, or damage |

| Temperature System Calibration | Annually | Calibrate thermocouples and PID controller for accuracy |

| Insulation and Seal Check | Monthly/Quarterly | Inspect for cracks or degradation to maintain efficiency |

Ensure your zirconia sintering furnace operates at peak performance with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, enhancing precision and efficiency. Contact us today to discuss how we can support your maintenance and upgrade requirements!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time