Using a dental furnace involves programming the device according to the specific ceramic material's requirements, executing a controlled heating cycle, and allowing for a gradual cooldown phase. This process sinters or glazes the ceramic restoration, such as a crown or bridge, giving it the required strength and aesthetic properties.

The key to effectively using a dental furnace is not just reaching a target temperature, but managing the entire thermal journey. Rushing the preheat or cooldown phases introduces thermal shock, which is the primary cause of fractures and failures in ceramic restorations.

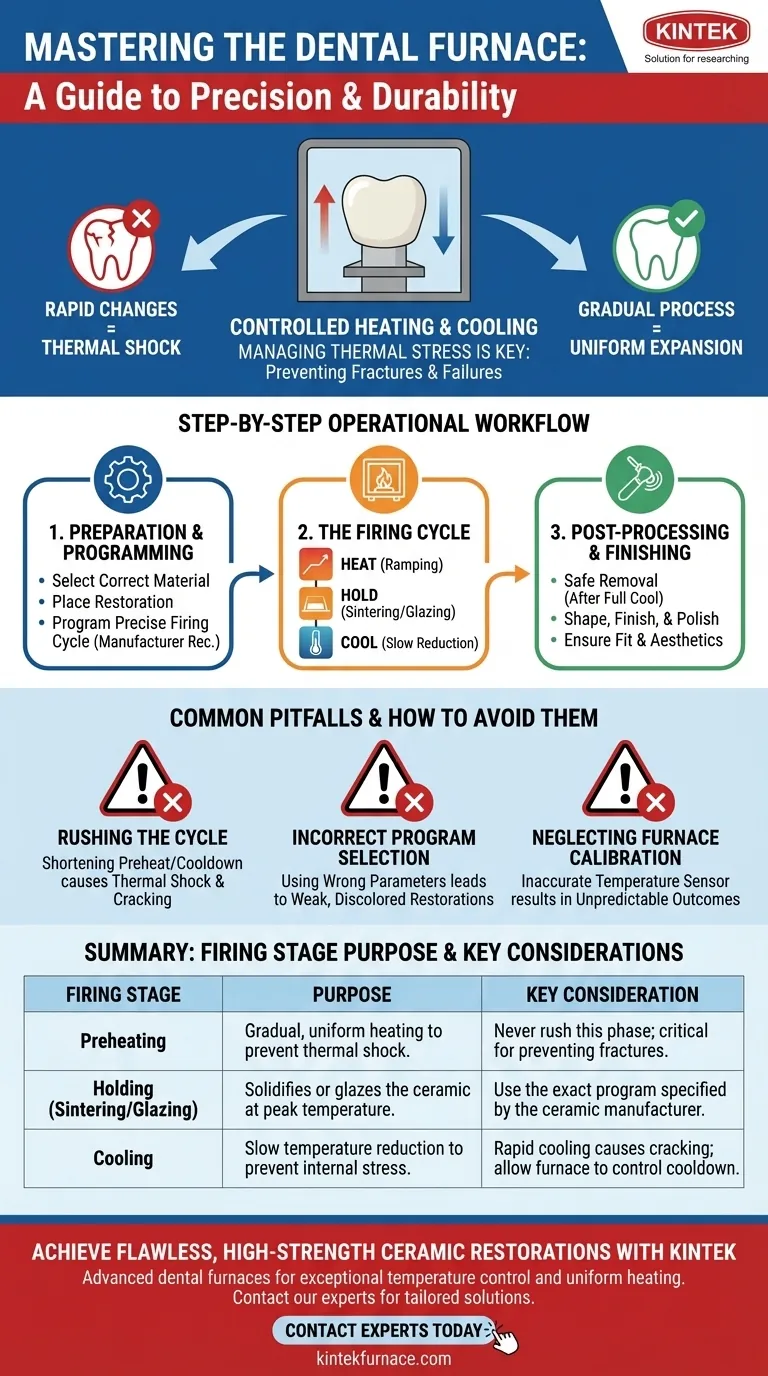

The Core Principle: Managing Thermal Stress

The fundamental purpose of a dental furnace is to apply heat in a highly controlled manner. Ceramic materials are brittle and expand or contract with temperature changes. If this change happens too quickly, the material cannot handle the internal stress, and it cracks.

Why Preheating is Non-Negotiable

The preheat phase slowly and evenly raises the temperature of the restoration. This gradual ramp-up allows the entire ceramic structure, from the surface to the core, to expand uniformly.

Skipping this step causes the outside of the restoration to heat and expand faster than the inside, creating immense internal stress that results in fractures.

The Critical Role of Controlled Cooling

Just as important as preheating is the cooldown phase. After the firing cycle is complete, the furnace must slowly lower the temperature.

Rapid cooling would cause the surface to shrink faster than the core, once again introducing stress that can lead to immediate or delayed cracking of the final prosthetic.

A Step-by-Step Operational Workflow

While specific furnace models vary, the universal process follows a clear and logical sequence designed to ensure consistent, high-quality results.

Step 1: Preparation and Programming

Before any heating begins, you must prepare the restoration and the furnace. This involves selecting the correct ceramic material for the case and placing the restoration inside the chamber.

Crucially, you must program the furnace with the precise firing cycle recommended by the ceramic's manufacturer. Every material has a unique recipe for temperature, ramp rate, and hold times.

Step 2: The Firing Cycle

Once programmed, the furnace executes the cycle automatically. This typically involves three stages:

- Heating (Ramping): The temperature rises at a controlled rate.

- Holding (Sintering/Glazing): The furnace maintains a peak temperature to solidify or glaze the ceramic.

- Cooling: The temperature is slowly reduced back to a safe level.

Step 3: Post-Processing and Finishing

After the furnace cycle is complete and the restoration has fully cooled, it can be safely removed. The final step involves shaping, finishing, and polishing the crown or bridge with specialized equipment to ensure a perfect fit and natural appearance.

Understanding the Common Pitfalls

Achieving consistent results means being aware of the trade-offs and avoiding common mistakes that compromise the integrity of the restoration.

Rushing the Cycle

The most common error is attempting to save time by shortening the preheat or cooldown phases. This is a false economy, as the high risk of thermal shock and cracking will lead to costly remakes and lost chair time.

Incorrect Program Selection

Using a firing program that does not match the specific ceramic material is a guaranteed path to failure. Each ceramic type has different thermal properties, and using the wrong parameters can result in a weak, discolored, or ill-fitting restoration.

Neglecting Furnace Calibration

Over time, a furnace's temperature sensor (thermocouple) can lose accuracy. An uncalibrated furnace might be running hotter or colder than it reports, making your precise programs useless. Regular calibration is essential for predictable and repeatable outcomes.

Making the Right Choice for Your Goal

Proper furnace operation is central to producing durable and aesthetic restorations. Your approach should align with your primary objective for each case.

- If your primary focus is durability and strength: Adhere strictly to the manufacturer's recommended preheat and cooldown schedules to eliminate internal stress.

- If your primary focus is aesthetic perfection: Ensure you use the exact program for the chosen ceramic to achieve the correct shade, translucency, and glaze.

- If your primary focus is practice efficiency: Prioritize correctness over speed by never skipping steps, which prevents costly remakes and ensures predictable results.

Mastering this process transforms the dental furnace from a simple oven into a precision tool for delivering superior patient outcomes.

Summary Table:

| Firing Stage | Purpose | Key Consideration |

|---|---|---|

| Preheating | Gradual, uniform heating to prevent thermal shock. | Never rush this phase; it's critical for preventing fractures. |

| Holding (Sintering/Glazing) | Solidifies or glazes the ceramic at peak temperature. | Use the exact program specified by the ceramic manufacturer. |

| Cooling | Slow temperature reduction to prevent internal stress. | Rapid cooling causes cracking; allow the furnace to control the cooldown. |

Achieve flawless, high-strength ceramic restorations with every firing.

At KINTEK, we understand that your success depends on precision and reliability. Our advanced dental furnaces are engineered for exceptional temperature control and uniform heating, giving you the confidence to master the thermal cycle. With our strong deep customization capability, we can provide a solution tailored to your lab's specific workflow and material requirements.

Ready to elevate your ceramic work and eliminate costly remakes? Contact our experts today to find the perfect furnace for your practice.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations