At a minimum, a modern sintering furnace must have redundant over-temperature protection, a clear emergency shut-off mechanism, and an earth leakage circuit breaker. These core features form the foundation of a system designed to prevent thermal runaway, provide manual override in a crisis, and protect operators from electrical shock.

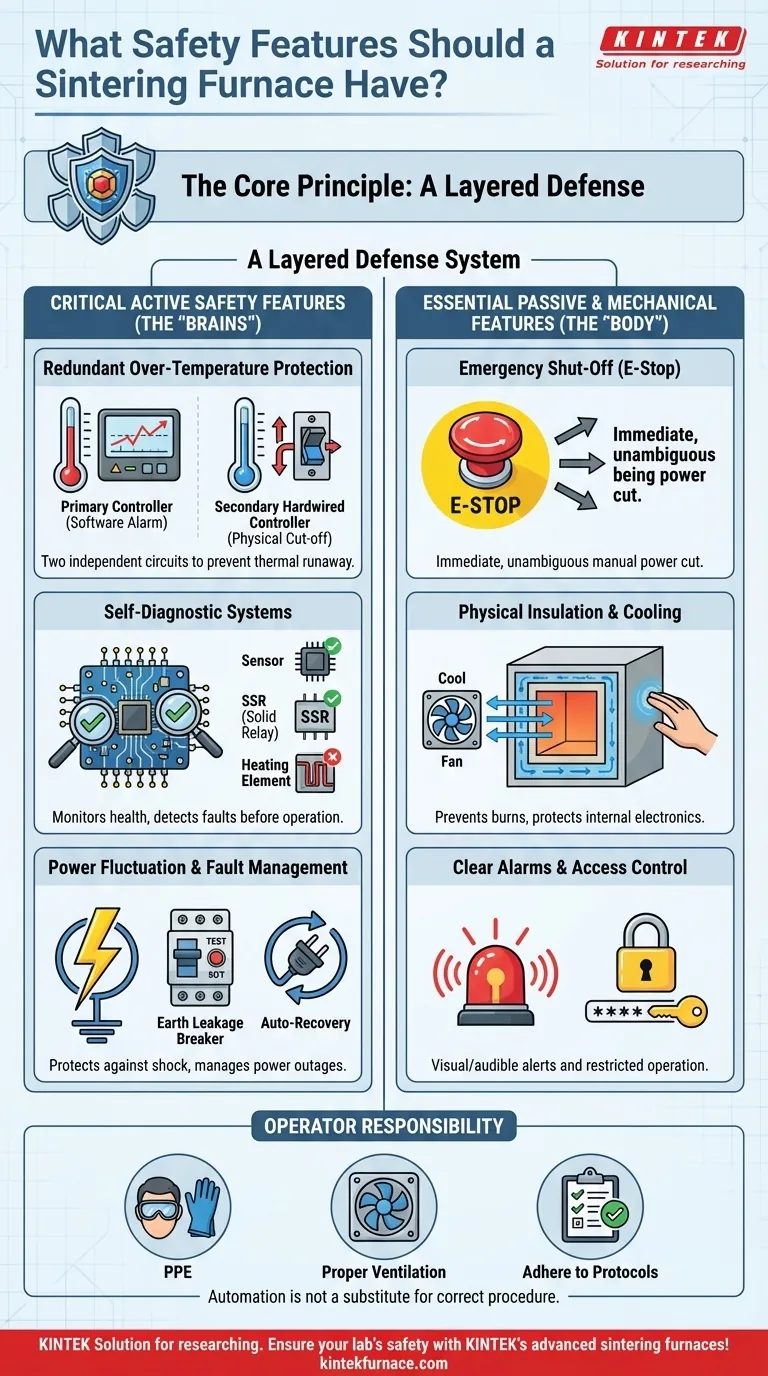

A sintering furnace is a high-energy system where safety is not achieved by a single feature, but through a layered defense. Understanding how these layers—from automated self-diagnostics to simple physical controls—work together is the key to ensuring safe, reliable, and repeatable operation.

The Core Principle: A Layered Defense

The most robust safety philosophies are built on the principle of redundancy. A single point of failure, whether it's a malfunctioning sensor or a software glitch, should never be capable of causing a catastrophic event.

A well-designed furnace anticipates potential failures and has backup systems in place to manage the risk. This layered approach creates a resilient system that protects the operator, the workpiece, and the equipment itself.

Critical Active Safety Features

Active safety systems are the "brains" of the furnace. They constantly monitor operating parameters and are programmed to intervene automatically when conditions deviate from the safe and expected range.

Redundant Over-Temperature Protection

This is the single most important safety system. Simply having one temperature limit is not enough.

A proper system uses two independent circuits. The primary controller manages the heating profile and will trigger a software alarm if the temperature exceeds the setpoint. A secondary, hardwired controller acts as a failsafe, physically cutting power to the heating elements if a much higher, critical temperature is reached. This protects against a failure of the primary control system (like a shorted SSR).

Self-Diagnostic Systems

Modern furnaces should be able to monitor their own health. Before a run ever begins, or even during operation, these systems check for common failure points.

Look for diagnostics that can detect a disconnected sensor, a shorted Solid State Relay (SSR), or a broken heating element. This preemptively identifies a fault that could otherwise lead to a dangerous thermal runaway or a failed process.

Power Fluctuation and Fault Management

The furnace must manage its connection to your facility's power grid safely.

An earth leakage breaker is non-negotiable. It immediately cuts power if it detects a current leak to the furnace chassis, preventing severe electrical shock. An auto-recovery function can also be a valuable safety and process feature, allowing the furnace to resume its heating cycle safely after a brief power outage.

Essential Passive and Mechanical Features

These features are the physical "body" of the furnace's safety design. They require direct operator interaction or provide inherent physical protection.

Emergency Shut-Off

Often called an E-stop, this is a large, conspicuous button that immediately and completely cuts all power to the heating systems. Its function must be unambiguous and instantly accessible. It is the final manual override when all automated systems fail or when an external emergency occurs.

Physical Insulation and Cooling

The furnace body must remain safe to the touch during high-temperature operation. A strongly cooled furnace body, typically using dual-wall construction with fan-assisted airflow, is critical. This not only prevents severe burns but also protects sensitive internal electronics from heat damage, ensuring their long-term reliability.

Clear Alarms and Access Control

Safety alerts are useless if they are not understood. The furnace must have clear visual and audible alarms for events like over-temperature conditions or system faults.

Additionally, a key lock function or password protection is a simple but effective feature. It prevents untrained personnel from operating the furnace or unintentionally altering critical process parameters.

Understanding the Trade-offs and Operator Responsibility

Not all safety systems are created equal, and no automated system can replace a trained, attentive operator.

Feature Quality vs. Presence

Simply having "over-temperature protection" on a specification sheet is not enough. The key is how it is implemented. Is it an independent, hardwired circuit, or just a software flag in the primary controller? A truly safe system will always have independent redundancy for critical functions.

Automation Is Not a Substitute for Procedure

The furnace's safety features are designed to protect the equipment and mitigate disaster. The operator's responsibility is to ensure day-to-day safety through correct procedure.

This includes always wearing appropriate Personal Protective Equipment (PPE), ensuring the furnace has proper ventilation for off-gassing, and strictly adhering to the manufacturer's operating protocols and temperature limits.

Making the Right Choice for Your Goal

When evaluating a sintering furnace, match its safety profile to your lab's specific operational needs and risk tolerance.

- If your primary focus is maximum safety and unattended operation: Prioritize furnaces with robust self-diagnostic systems, fully independent over-temperature protection, and clear, actionable alarms.

- If your primary focus is processing standard materials on a budget: Ensure the non-negotiable basics are present: a hardwired over-temperature cutoff, a tested emergency shut-off, and an earth leakage breaker.

- If you are auditing an existing furnace: Perform regular functional tests of the E-stop, verify the secondary over-temperature setting is correct, and confirm all alarms are operational.

Ultimately, furnace safety is a result of deliberate design and disciplined operation.

Summary Table:

| Safety Feature | Purpose | Key Details |

|---|---|---|

| Redundant Over-Temperature Protection | Prevents thermal runaway | Uses primary and secondary controllers for independent monitoring |

| Emergency Shut-Off | Allows manual override in crises | Large, accessible button that cuts all power instantly |

| Earth Leakage Circuit Breaker | Protects against electrical shock | Cuts power if current leaks to the furnace chassis |

| Self-Diagnostic Systems | Monitors furnace health | Detects issues like disconnected sensors or broken elements |

| Physical Insulation and Cooling | Prevents burns and protects components | Dual-wall construction with fan-assisted airflow |

| Clear Alarms and Access Control | Ensures alerts are understood and restricts access | Visual/audible alarms and key lock or password protection |

Ensure your lab's safety and efficiency with KINTEK's advanced sintering furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, integrating critical safety features like redundant over-temperature protection and emergency shut-offs. Don't compromise on safety—contact us today to discuss how our furnaces can protect your operations and enhance performance!

Visual Guide

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the core advantage of using a Hot Pressing Sintering (HPS) furnace? Enhance SiC/YAG Ceramic Density & Strength

- How does temperature control at 950°C affect SiC/Cu-Al2O3 composites? Optimize Sintering for High Strength

- Why is multi-stage pressure regulation required in a vacuum hot press furnace? Optimize Ti-Al3Ti Composite Sintering

- What is the core processing value of a vacuum hot pressing sintering furnace? Master AZ31 Magnesium Alloy Density

- How does the programmable pressure function of a vacuum hot press furnace influence the quality of IZO targets?