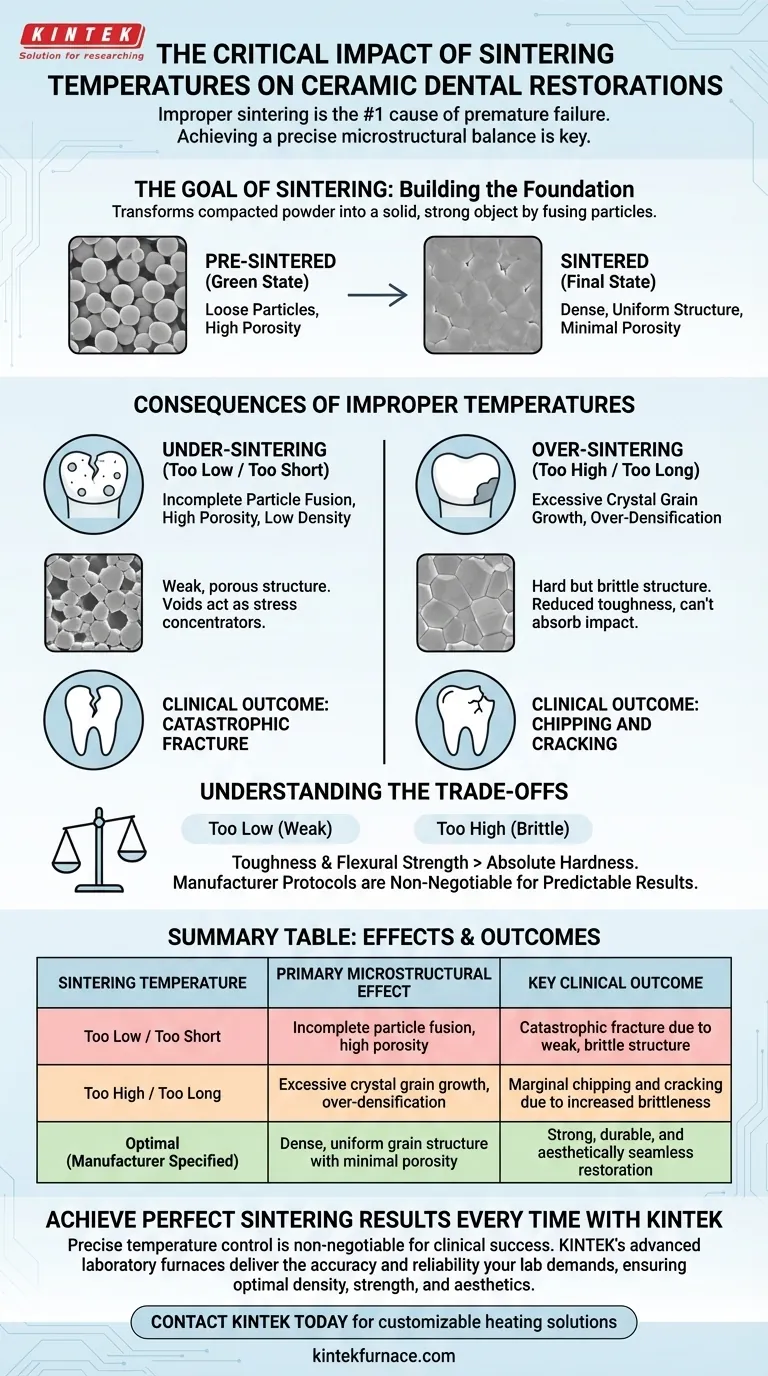

Using an improper sintering temperature is the single most common cause of premature failure in ceramic dental restorations. Firing a ceramic at the wrong temperature—whether too high or too low—critically undermines its final structural integrity. A temperature that is too low results in a weak, porous restoration prone to complete fracture, while a temperature that is too high creates an overly dense, brittle material susceptible to chipping and cracking.

The core purpose of sintering is to achieve a precise microstructural balance of density and grain size. Deviating from the manufacturer's specified temperature disrupts this balance, creating a restoration that is guaranteed to fail under the normal stresses of clinical function.

The Goal of Sintering: Building the Ceramic Foundation

Sintering is a thermal process that transforms a compacted ceramic powder (the "green state") into a dense, solid object. This occurs at temperatures below the material's melting point.

From Loose Particles to a Solid Mass

Think of the pre-sintered ceramic as a container of tightly packed sand. While it holds a shape, the individual grains are not bonded.

The sintering process applies controlled heat, causing the surfaces of these particles to fuse together. This process eliminates the empty spaces (pores) between them, increasing the material's overall density and strength.

Achieving Optimal Microstructure

The final strength, toughness, and even the esthetics of a ceramic restoration are dictated by its internal microstructure.

The ideal structure is a dense, uniform arrangement of crystals with minimal porosity. This allows occlusal forces to be distributed evenly throughout the restoration, preventing stress from concentrating in any single weak point.

The Consequences of Under-Sintering (Too Low / Too Short)

When the furnace temperature is too low or the holding time is insufficient, the ceramic does not receive enough thermal energy to complete the densification process.

Incomplete Particle Fusion

The atomic diffusion process that bonds the ceramic particles together is incomplete. The "necks" that form between individual grains are underdeveloped and weak.

High Porosity and Low Density

Significant voids remain within the material's structure. These pores act as internal stress concentrators, becoming the starting points for cracks when the restoration is put under load.

Clinical Outcome: Catastrophic Fracture

An under-sintered restoration is fundamentally weak and brittle. It cannot withstand normal chewing forces and is highly susceptible to a complete, catastrophic fracture, often rendering the entire restoration unusable.

The Consequences of Over-Sintering (Too High / Too Long)

Exposing the ceramic to excessive heat or holding it at the peak temperature for too long is equally damaging, though it leads to a different mode of failure.

Excessive Crystal Grain Growth

While the material becomes very dense, the high thermal energy causes the individual crystal grains to grow abnormally large. This process reduces the material's ability to resist crack propagation.

Reduced Toughness and Increased Brittleness

A material with very large grains is typically very hard but also extremely brittle. It loses its "toughness"—the ability to absorb small amounts of energy without fracturing.

Clinical Outcome: Chipping and Cracking

An over-sintered restoration will feel hard but will not be durable. It cannot flex or absorb impact, making it highly prone to chipping along the margins and developing stress cracks over time.

Understanding the Trade-offs

Achieving a successful clinical outcome requires moving beyond a simplistic view of the material's properties. It is a process of precision, not approximation.

The Myth of "Harder is Better"

Over-sintering creates a harder but more brittle material. In dentistry, toughness and flexural strength are more important than absolute hardness. A restoration must be able to withstand millions of chewing cycles, which requires a material that can manage stress, not just resist scratching.

Impact on Esthetics and Fit

Improper temperatures also affect the final shade and translucency of the ceramic, leading to a poor esthetic match. Furthermore, it can cause unpredictable shrinkage, compromising the marginal fit of the restoration.

Manufacturer Protocols Are Non-Negotiable

Every ceramic system has a unique chemical composition designed to mature at a specific temperature and heating rate. These protocols are the result of extensive research and must be followed precisely. Calibrating your furnace regularly is essential to ensure you are delivering the correct temperature.

How to Ensure Optimal Sintering for Clinical Success

Your approach to sintering should be guided by the desired clinical outcome: a restoration that is both durable and predictable.

- If your primary focus is preventing catastrophic fractures: You must ensure the ceramic receives enough thermal energy to fully densify. Never cut firing times short or use a temperature below the manufacturer's recommendation.

- If your primary focus is avoiding marginal chipping and long-term cracks: You must prevent the formation of a brittle microstructure by strictly avoiding temperatures that are too high or hold times that are too long.

- If your primary focus is achieving consistent, predictable results: Treat the manufacturer's firing schedule as a precise prescription, not a general guideline, and ensure your furnace is calibrated to deliver it accurately every time.

Ultimately, a perfectly executed sintering cycle is the foundation for creating a restoration that is strong, durable, and esthetically seamless.

Summary Table:

| Sintering Temperature | Primary Microstructural Effect | Key Clinical Outcome |

|---|---|---|

| Too Low / Too Short | Incomplete particle fusion, high porosity | Catastrophic fracture due to weak, brittle structure |

| Too High / Too Long | Excessive crystal grain growth, over-densification | Marginal chipping and cracking due to increased brittleness |

| Optimal (Manufacturer Specified) | Dense, uniform grain structure with minimal porosity | Strong, durable, and aesthetically seamless restoration |

Achieve Perfect Sintering Results Every Time

Don't let improper sintering compromise the quality and longevity of your dental restorations. Precise temperature control is non-negotiable for clinical success.

KINTEK's advanced laboratory furnaces are engineered to deliver the accuracy and reliability your dental lab demands. Our Muffle and Tube Furnaces provide the uniform heating and precise temperature profiles required to follow manufacturer sintering protocols exactly, ensuring optimal density, strength, and aesthetics for every restoration.

Ready to eliminate sintering failures and achieve consistent, predictable results?

Contact KINTEK today to discuss how our customizable heating solutions can enhance your workflow and ensure the clinical success of your ceramic restorations.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency