The stability of microstructural properties in die steels is achieved through the box resistance furnace's ability to maintain a highly uniform thermal field and precise temperature cycles. This controlled environment facilitates the complete dissolution of alloying elements and the subsequent uniform precipitation of fine carbides. By regulating these thermal phases with high accuracy, the furnace ensures consistent hardness and a homogeneous internal structure across all treated samples.

A box resistance furnace provides the stable thermal foundation necessary to standardize microstructural evolution, specifically through precise carbide management and the elimination of chemical segregation. This technical precision allows for the achievement of specific hardness benchmarks, which is critical for the scientific validity of subsequent performance testing.

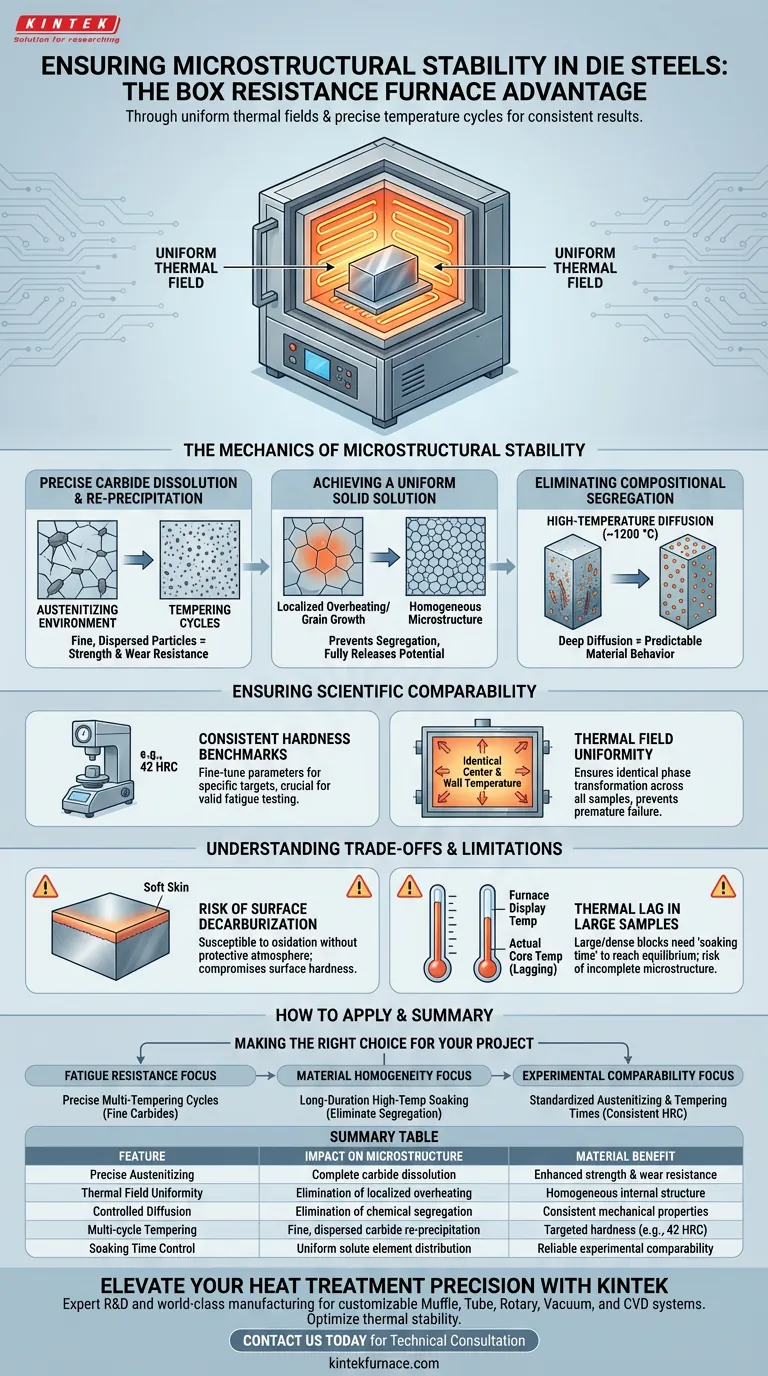

The Mechanics of Microstructural Stability

Precise Carbide Dissolution and Re-precipitation

The furnace provides a stable austenitizing environment that allows carbides within the die steel to dissolve fully into the matrix. Following this, the system executes multiple tempering cycles to ensure these carbides re-precipitate as fine, dispersed particles. This specific transformation is what gives the steel its final strength and wear resistance.

Achieving a Uniform Solid Solution

By maintaining a constant temperature over extended periods, the furnace allows solute elements to distribute uniformly within the metallic matrix. This prevents "localized overheating," which can cause grain growth, or "insufficient solid solution," which leaves the material weak. The result is a homogeneous microstructure that can fully release its potential for precipitation strengthening.

Eliminating Compositional Segregation

High-temperature box furnaces, often operating around 1200 °C, facilitate the deep diffusion of alloying elements. This prolonged, stable heat is essential for eliminating compositional segregation in ingots or complex alloys. A uniform chemical distribution ensures that the material behaves predictably during machining and final use.

Ensuring Scientific Comparability

Consistent Hardness Benchmarks

In a research or industrial setting, different steel samples must often reach a consistent hardness benchmark (such as 42 HRC) before testing. The box resistance furnace allows for the fine-tuning of thermal parameters to hit these specific targets accurately. This level of control ensures that any subsequent data, such as fatigue testing results, is scientifically valid and comparable.

Thermal Field Uniformity

The design of the furnace chamber is optimized for thermal field uniformity, meaning the temperature at the center is identical to the temperature near the walls. This uniformity ensures that every part of the die steel undergoes the exact same phase transformation. Without this, a single batch of steel could exhibit varying mechanical properties, leading to premature tool failure.

Understanding the Trade-offs and Limitations

The Risk of Surface Decarburization

While box resistance furnaces excel at temperature stability, they often operate with a standard atmospheric composition. Without a protective gas or vacuum, die steels held at high temperatures for long periods are susceptible to oxidation and decarburization. This can create a soft "skin" on the material that compromises surface hardness.

Thermal Lag in Large Samples

Users must account for the difference between the furnace's displayed temperature and the actual core temperature of the steel. Because box furnaces rely on radiation and convection, large or dense die blocks may require significant "soaking time" to reach equilibrium. Failure to account for this lag can lead to an incomplete internal microstructure despite the furnace reading the correct temperature.

How to Apply This to Your Heat Treatment Goals

Making the Right Choice for Your Project

To maximize the effectiveness of a box resistance furnace, the heating profile must be tailored to the specific metallurgical requirements of the steel grade.

- If your primary focus is fatigue resistance: Utilize precise multiple tempering cycles to ensure carbides are fine and dispersed rather than coarse.

- If your primary focus is material homogeneity: Prioritize long-duration high-temperature soaking to eliminate chemical segregation and ensure a uniform solid solution.

- If your primary focus is experimental comparability: Standardize your austenitizing and tempering times to reach a specific HRC benchmark across all test samples.

By mastering the thermal environment of the box resistance furnace, you ensure that the microstructural integrity of your die steel is a constant rather than a variable.

Summary Table:

| Feature | Impact on Microstructure | Material Benefit |

|---|---|---|

| Precise Austenitizing | Complete carbide dissolution into the matrix | Enhanced strength & wear resistance |

| Thermal Field Uniformity | Elimination of localized overheating/grain growth | Homogeneous internal structure |

| Controlled Diffusion | Elimination of chemical segregation | Consistent mechanical properties |

| Multi-cycle Tempering | Fine, dispersed carbide re-precipitation | Targeted hardness (e.g., 42 HRC) |

| Soaking Time Control | Uniform solute element distribution | Reliable experimental comparability |

Elevate Your Heat Treatment Precision with KINTEK

Ensure perfect microstructural integrity for your die steels with KINTEK’s high-performance laboratory solutions. Backed by expert R&D and world-class manufacturing, we provide a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific temperature and atmospheric requirements.

Whether you need to eliminate chemical segregation or achieve precise hardness benchmarks, our furnaces offer the thermal stability your research or production demands.

Ready to optimize your thermal processing? Contact us today to discuss your unique needs with our technical team!

Visual Guide

References

- Yasha Yuan, Jingpei Xie. Strain-Controlled Thermal–Mechanical Fatigue Behavior and Microstructural Evolution Mechanism of the Novel Cr-Mo-V Hot-Work Die Steel. DOI: 10.3390/ma18020334

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of the heating and holding curves in a muffle furnace? Sinter High-Quality PTFE Composites

- What is the primary function of a muffle furnace during SCBA pretreatment? Mastering Sugarcane Bagasse Carbonization

- Why are modern muffle furnaces considered energy-efficient? Discover Key Innovations for Lower Costs

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What was the initial purpose of a muffle furnace and how has it evolved? Discover Its Journey from Contamination Shield to Precision Tool

- What factors should users consider when selecting a box type resistance furnace? Key Insights for Optimal Performance

- What are the technical advantages of using an infrared heating furnace for the fast pyrolysis of cellulose? Higher Yields

- What should be considered about crucible size when choosing a muffle furnace? Optimize for Safety and Efficiency