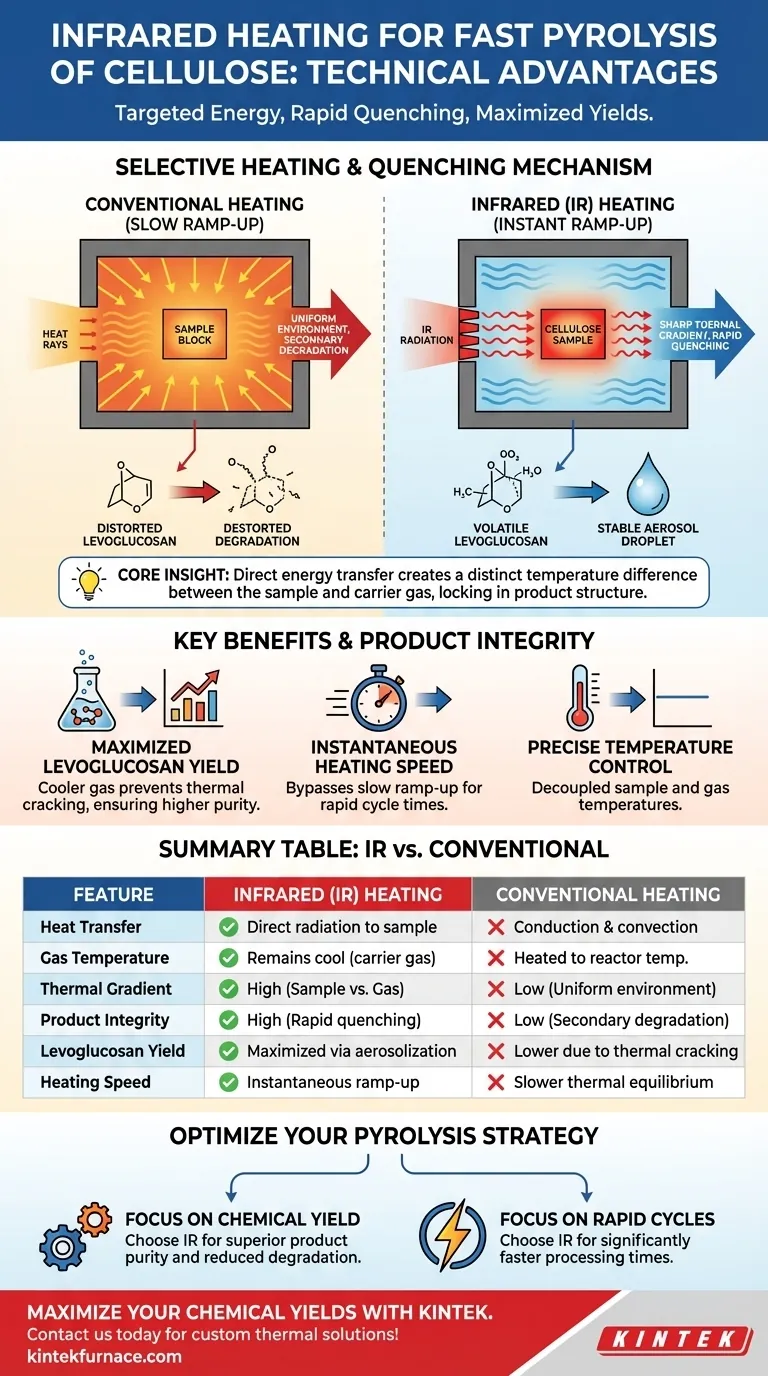

The primary technical advantage of infrared (IR) heating in cellulose fast pyrolysis is its ability to selectively target the sample material without overheating the surrounding environment. Unlike conventional methods that rely on heating the entire reactor volume, IR radiation transfers energy directly to the cellulose, achieving decomposition temperatures rapidly while keeping the carrier gas relatively cool.

Core Insight The effectiveness of infrared heating relies on creating a sharp temperature gradient between the sample and the carrier gas. This allows volatile compounds to escape the hot zone and immediately quench in the cooler gas, effectively locking in their chemical structure and preventing degradation.

The Mechanics of Selective Heating

Targeting the Material, Not the Medium

Conventional heating methods typically transfer heat via conduction or convection, requiring the reactor walls and the carrier gas to reach high temperatures first.

Infrared heating bypasses this limitation by using radiation to transfer energy directly to the cellulose sample.

Decoupling Gas and Sample Temperatures

Because the energy is targeted, the surrounding carrier gas (such as nitrogen) remains at a significantly lower temperature than the decomposing sample.

This creates a distinct thermal environment that is impossible to achieve with standard resistance or convection furnaces, where the gas is often the primary heat transfer medium.

Preserving Product Integrity

The "Quench" Effect

When cellulose decomposes, it releases volatile organic compounds. In a uniformly hot reactor, these compounds remain at high temperatures, leading to unwanted secondary reactions.

In an IR furnace, these volatiles exit the heated cellulose and immediately enter the cooler carrier gas stream.

Maximizing Levoglucosan Yield

The primary reference highlights that this specific temperature gradient forces volatile levoglucosan to cool rapidly into aerosols.

By transitioning quickly from a hot vapor to a stable aerosol, the process prevents secondary thermal degradation, ensuring a higher purity and yield of the target chemical product.

Understanding the Trade-offs

Material Absorption Dependency

While IR heating is highly efficient for cellulose, its effectiveness depends on the material's ability to absorb infrared radiation.

If a sample or a specific additive reflects IR wavelengths, the heating rate may become inconsistent or inefficient compared to conductive methods.

Process Sensitivity

The rapid nature of IR heating requires precise control over exposure times.

Because the sample heats much faster than the environment, slight over-exposure can lead to charring before the volatiles have a chance to escape and quench.

Optimizing Your Pyrolysis Strategy

To determine if an infrared furnace is the right tool for your specific application, consider your primary technical objectives:

- If your primary focus is maximizing chemical yield: The IR method is superior because the cool carrier gas prevents secondary degradation of sensitive compounds like levoglucosan.

- If your primary focus is rapid cycle times: IR heating offers the advantage of reaching decomposition temperatures almost instantly, bypassing the slow ramp-up times of conventional ovens.

By leveraging the thermal gradient unique to infrared heating, you can achieve a level of chemical selectivity that conventional bulk heating simply cannot match.

Summary Table:

| Feature | Infrared (IR) Heating | Conventional Heating |

|---|---|---|

| Heat Transfer | Direct radiation to sample | Conduction and convection |

| Gas Temperature | Remains cool (carrier gas) | Heated to reactor temperature |

| Thermal Gradient | High (Sample vs. Gas) | Low (Uniform environment) |

| Product Integrity | High (Rapid quenching) | Low (Secondary degradation) |

| Levoglucosan Yield | Maximized via aerosolization | Lower due to thermal cracking |

| Heating Speed | Instantaneous ramp-up | Slower thermal equilibrium |

Maximize Your Chemical Yields with KINTEK

Don't let secondary reactions compromise your research results. KINTEK’s high-precision heating solutions, backed by expert R&D and world-class manufacturing, provide the thermal control necessary for advanced applications like cellulose pyrolysis.

Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our laboratory high-temp furnaces are fully customizable to meet your unique experimental needs. Leverage our expertise to achieve superior material decomposition and product purity.

Ready to upgrade your lab’s thermal capabilities? Contact us today to find your custom solution!

Visual Guide

References

- Takashi Nomura, Haruo Kawamoto. Purity improvement and efficient recovery of levoglucosan mist produced by fast pyrolysis of cellulose using corona discharge. DOI: 10.1039/d5ra01634g

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are some specific processes modern Muffle Furnaces can perform? Unlock Precision in High-Temperature Applications

- What function does a high-temperature muffle furnace serve in ceramic membrane substrate preparation?

- Why is a high-temperature muffle furnace required for 1000 Celsius aging treatment? Evaluate CeZrPAl Durability

- What is a box furnace? A Versatile Tool for Precise Heat Treatment

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What functions do drying ovens and sintering furnaces serve in Sol-Gel? Optimize Bioactive Coating Integrity

- How is a muffle furnace utilized during the secondary thermal decomposition of ZnCl2-impregnated biochar?

- How does a high-temperature box muffle furnace convert mussel shells to calcium oxide? Expert Calcination Guide